Oyster calcining technological process

A process method, oyster calcination technology, applied in the direction of medical formula, medical preparations containing active ingredients, unknown raw materials, etc., can solve the problems of labor-intensive production, uneven quality, unfavorable large-scale production, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] 1. Experimental equipment:

[0024] Muffle furnace, Shanghai Precision Scientific Instrument Co., Ltd., SX2-4-10 type;

[0025] Analytical balance, Shanghai Precision Scientific Instrument Co., Ltd., HANK-P N FA1104N;

[0026] Tablet hardness tester, Shanghai Huanghai Drug Testing Instrument Co., Ltd., YPD-200C type.

[0027] 2. Experimental method:

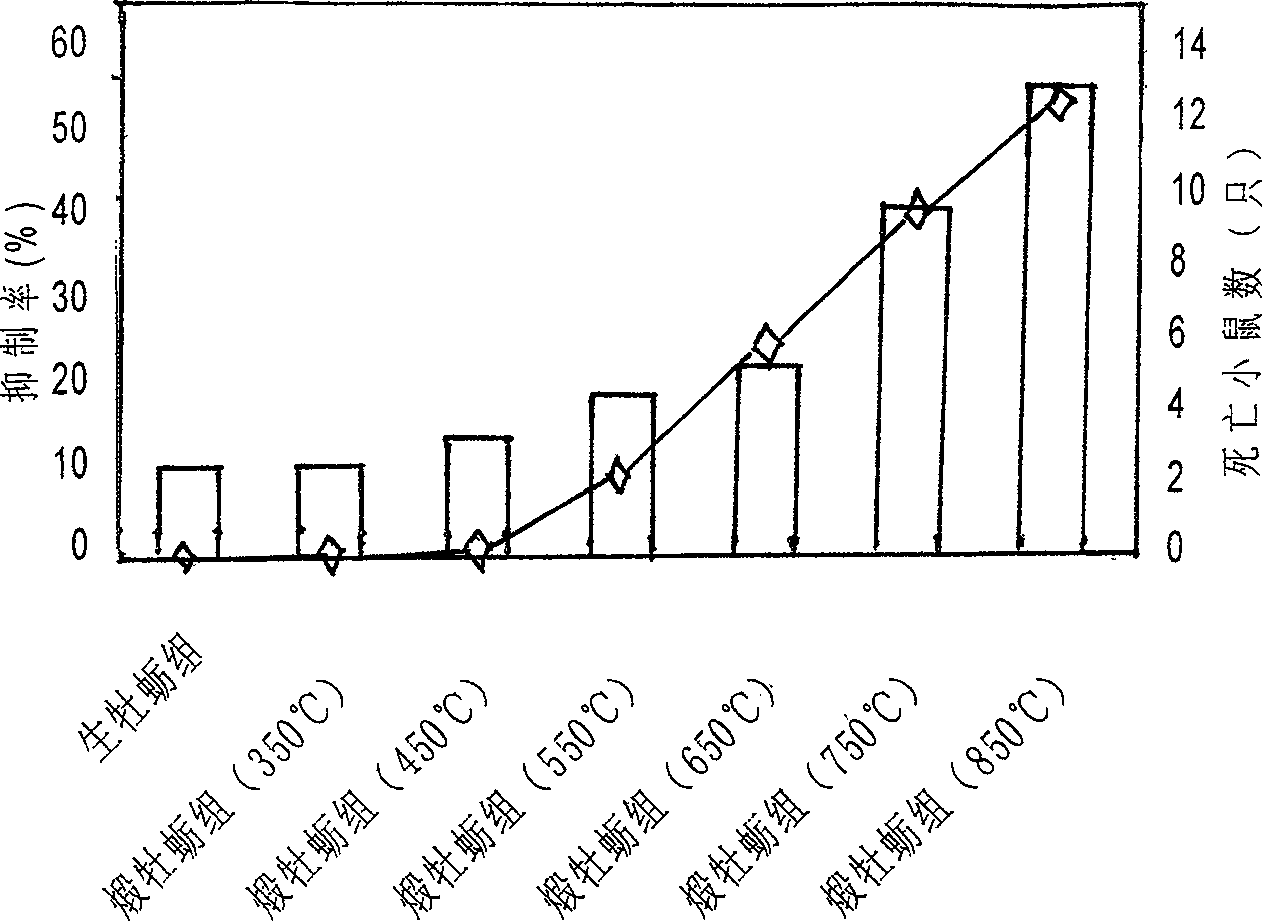

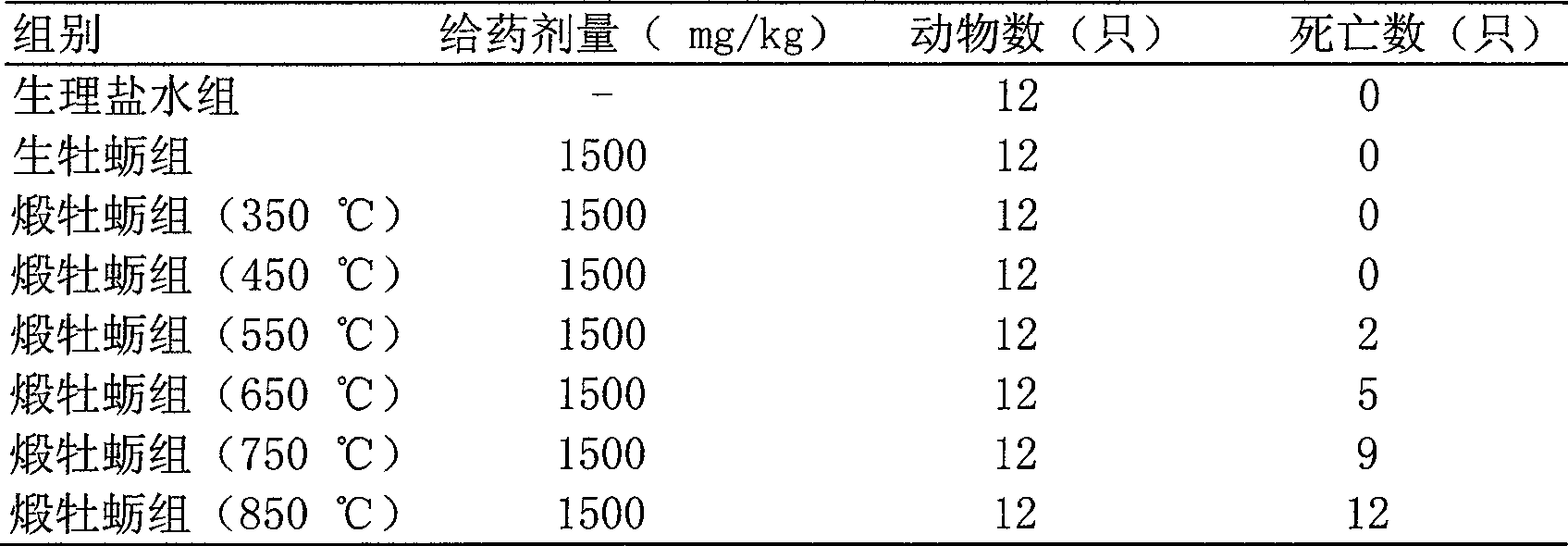

[0028] 2.1 Take 120 qualified male mice, weighing about 18-22g, and randomly divide them into blank control group (normal saline group), raw oyster group 1500g / kg, calcined oyster group (350°C, 450°C, 550°C, 650°C, 750°C, 850°C), 1500mg / kg, the animals were given the test drug (0.1ml / 10g) twice a day for a total of 7 days. The experimental results are shown in Table 1

[0029] Table 1 Results of mouse toxicity test

[0030]

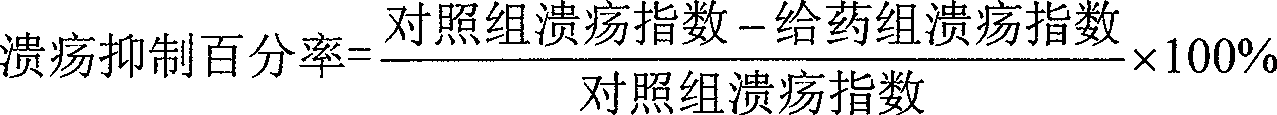

[0031] 2.2 Male SD rats weighing 180-200g were randomly divided into blank control group, model control group, positive control group and drug treatment group after weighing. Animals in the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com