Calcining method of lapis chloriti potassium nitrate

A technology for green stone and green stone raw products, applied in the field of traditional Chinese medicine, can solve the problems of uneven quality, time-consuming, labor-intensive production, etc., and achieve the effects of increasing safety, increasing the dissolution rate, and reducing the content of harmful elements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Example 1 Method for calcining bluestone and fire nitrate

[0018] Crush the bluestone into small pieces of 2~5mm, wash and dry; take the raw bluestone with a weight ratio of 1:0.1~1:2.5 and mix well, and spread on 100ml with a thickness of 2~10cm Put the crucible into a muffle furnace and calcinate at a high temperature of 500~900℃ for 1~4h to obtain the sintered bluestone.

Embodiment 2

[0019] Example 2 Research on the calcination process of bluestone and fire nitrate

[0020] ⑴ Experimental method

[0021] Evaluation indicators for calcined products: the color, porosity, and water-soluble dissolution rate of calcined products are taken as indicators for evaluating the effect of calcining. The scoring rules are as follows:

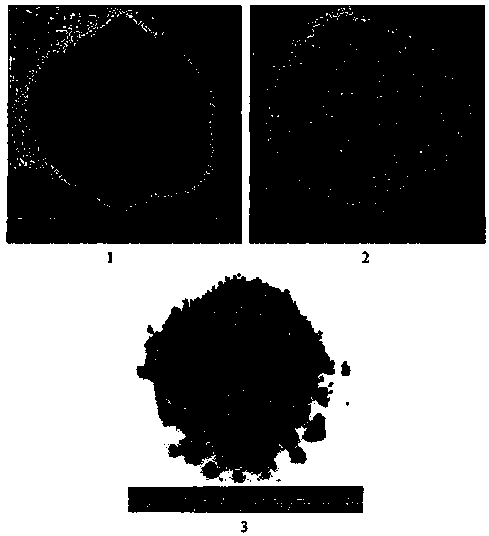

[0022] (1) The color of the calcined product: 10 points for golden yellow, 6 points for dark yellow brown, 4 points for no yellow appearance;

[0023] (2) The porosity of the calcined product: the calcined product is loose (good fluidity, no agglomeration) as 10 points, relatively loose or crisp (some agglomerated, but loose with a little force) is rated as 6 points, and the hardness is evaluated. It is 4 points.

[0024] (3) Water-soluble dissolution rate: calculate the water-soluble dissolution rate of the sample based on the dried product.

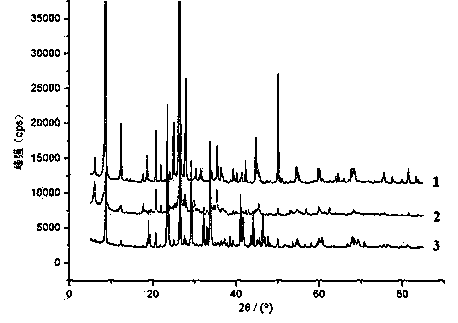

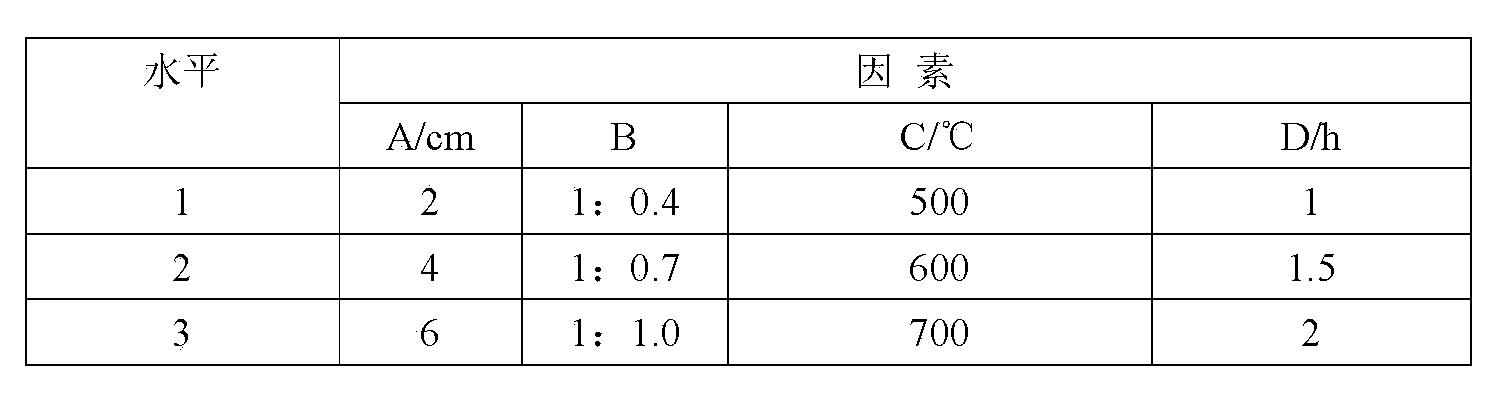

[0025] Experimental design: adopt L 9 (3 4 ) Orthogonal table examines the layer thickness (A), the mass ...

Embodiment 3

[0036] Example 3 Verification of the calcination process of bluestone and fire nitrate

[0037] Three batches of samples were prepared according to the optimized conditions for the calcination of bluestone and fire nitrate in Example 2. The results showed that the color was golden yellow, the samples were loose, and the water-soluble dissolution rates were 29.48%, 29.47%, and 29.43%, indicating the optimal process The conditions are stable, reasonable and feasible.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com