Robot toy and assembling method thereof

An assembly method and robot technology, which can be used in toys, automatic toys, instruments, etc., and can solve problems such as complicated operations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] Next, the robot toy according to the present invention will be described.

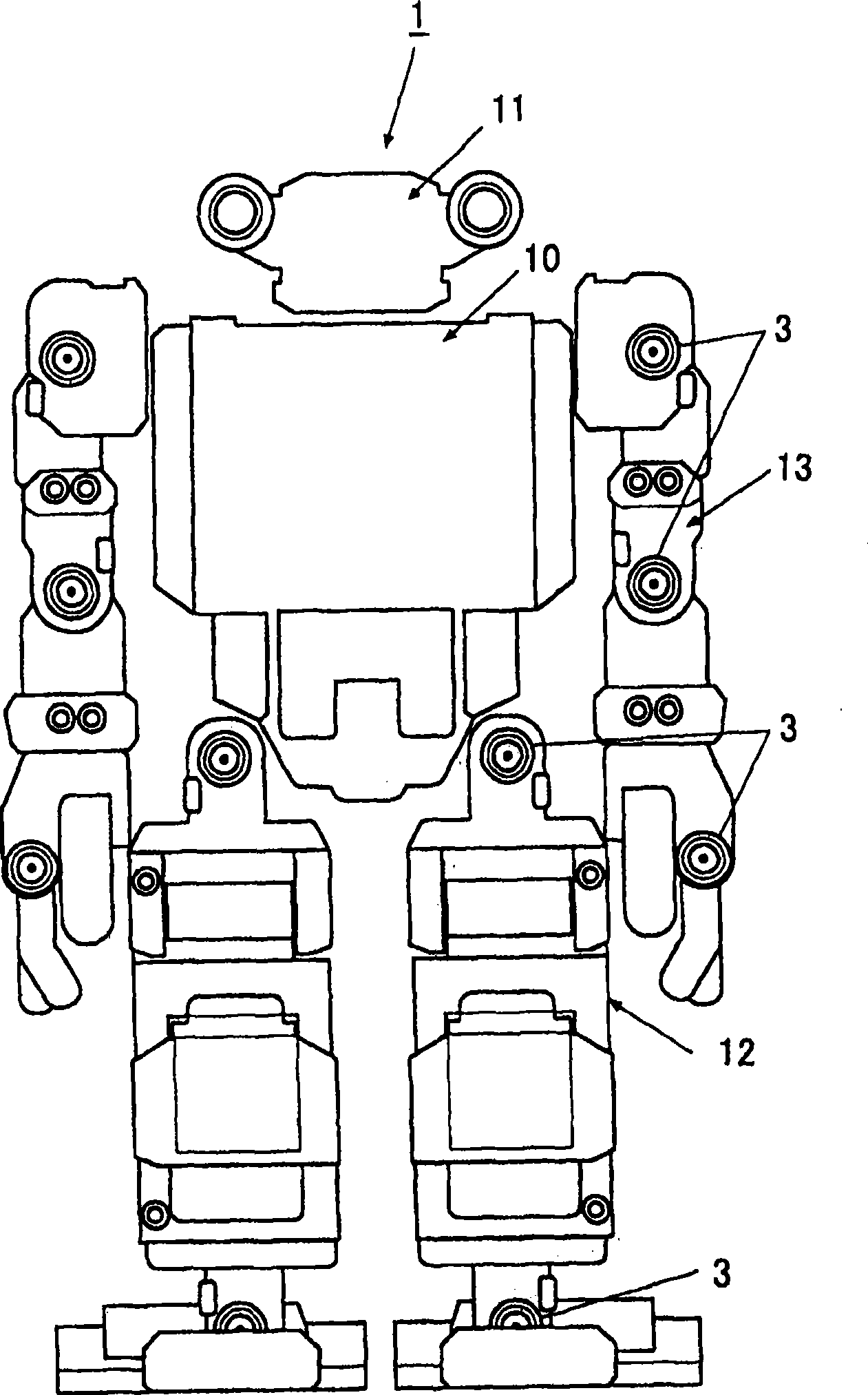

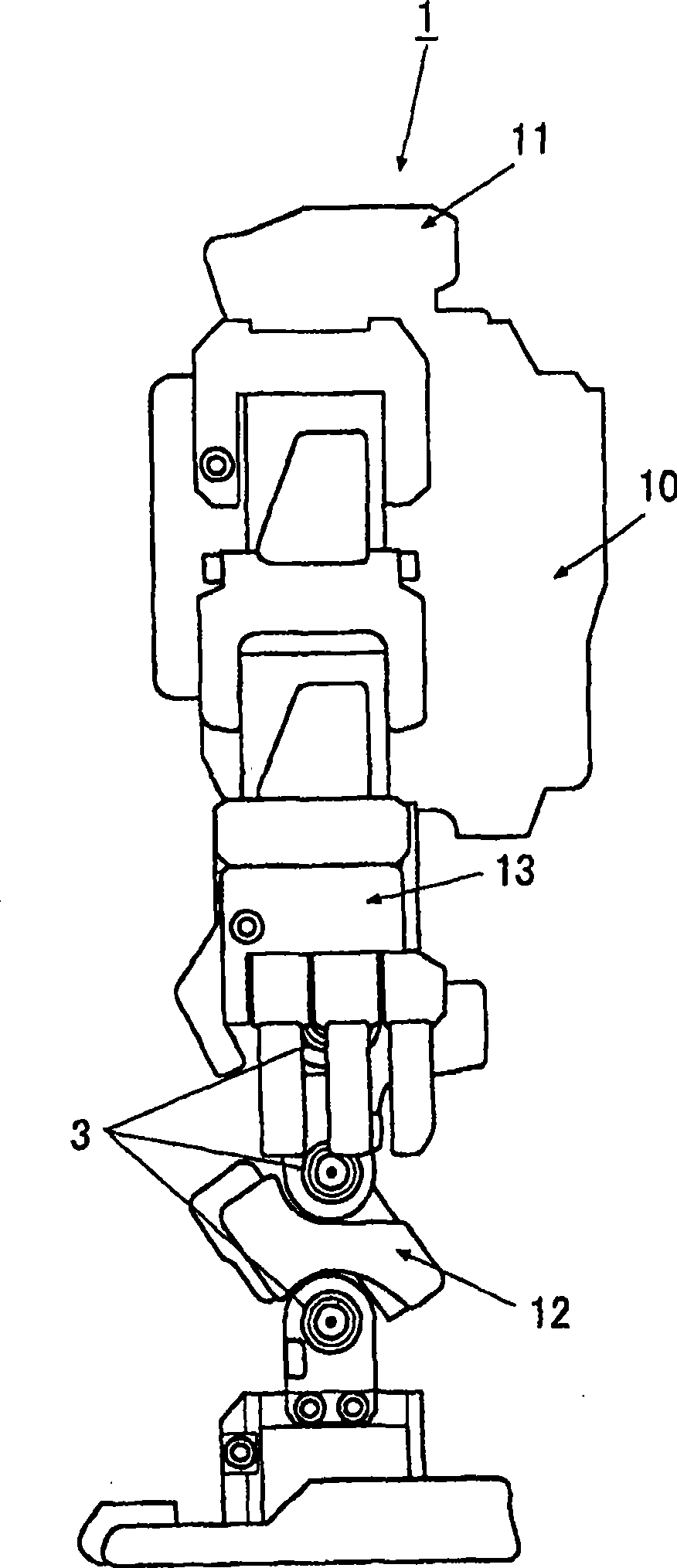

[0050] figure 1 It is a front view of the robot toy 1 in this embodiment, figure 2 is the right side view of the robot toy 1.

[0051] The robot toy 1 is a toy whose operation is remotely controlled by the operation of a controller not shown. Specifically, this robot toy 1 includes: a torso 10, a head 11, a leg 12, and a hand 13. The joints of the legs 12 and the hand 13 are respectively assembled with a robot that is driven according to the operation of the controller. Servo Mechanism 3.

[0052] [Configuration of Servo Mechanism]

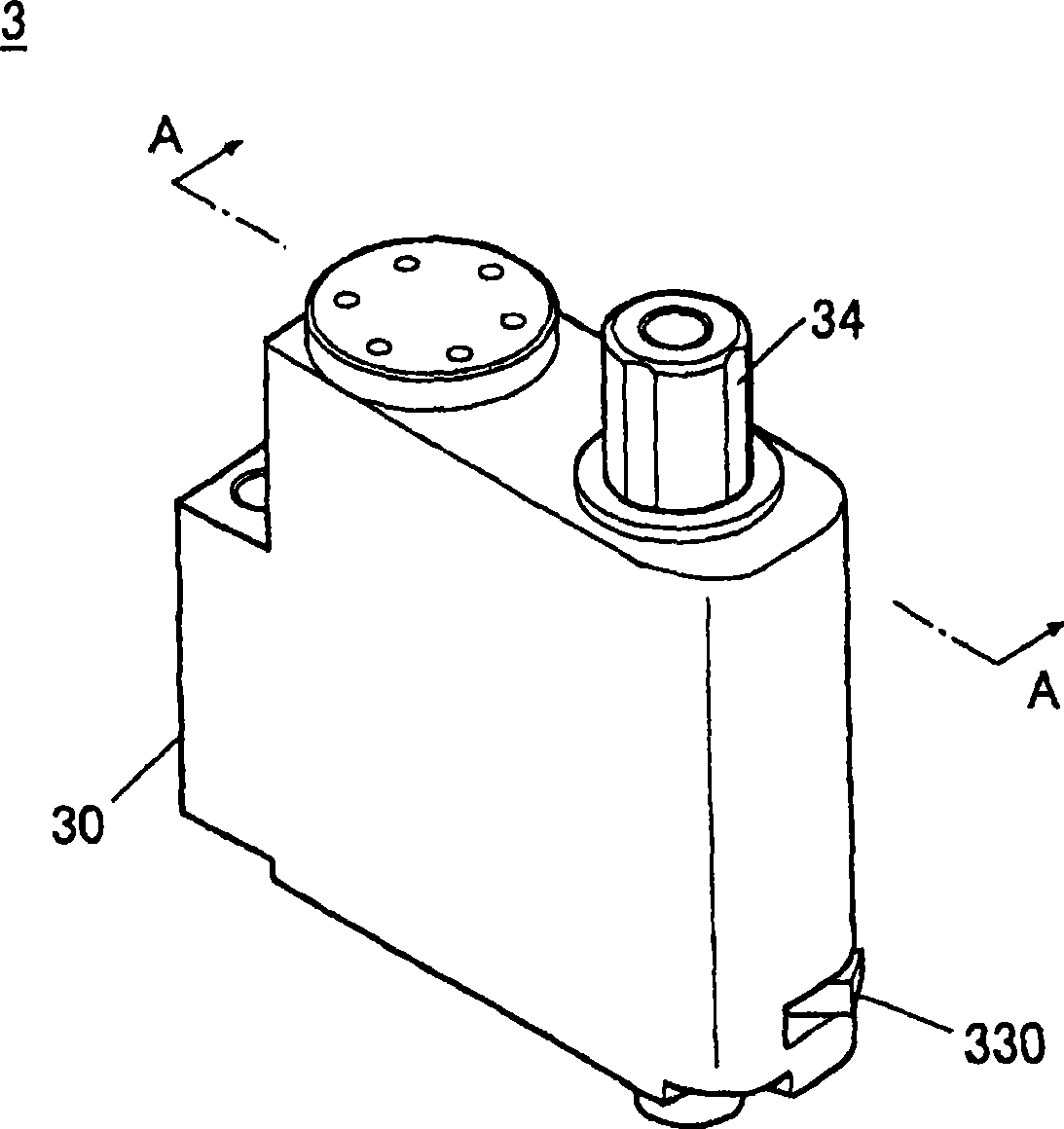

[0053] Such as image 3 , Figure 4 As shown, the servo mechanism 3 rotates and drives the output shaft 34 , and includes a servo motor 31 , a reduction gear mechanism 32 , and a potentiometer 33 inside the housing 30 .

[0054] Among them, the servo motor 31 is used to rotate the reduction gear mechanism 32 .

[0055] The reduction gear mechanism 32 has gear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com