Polar coordinate mode horizontal automatic regulating cargo sling and method

An automatic adjustment and polar coordinate technology, applied in the direction of load hanging components, transportation and packaging, etc., can solve the problems of easy swing, drastic angle change, large bending moment change, etc., and achieve the effect of time-consuming solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The preferred embodiments of the present invention are introduced below, and this part is only an illustration of the present invention, rather than limiting the present invention and its application or use. Other implementation modes obtained according to the present invention also belong to the technical innovation scope of the present invention. The setting of relevant parameters in the scheme does not mean that only example values can be used.

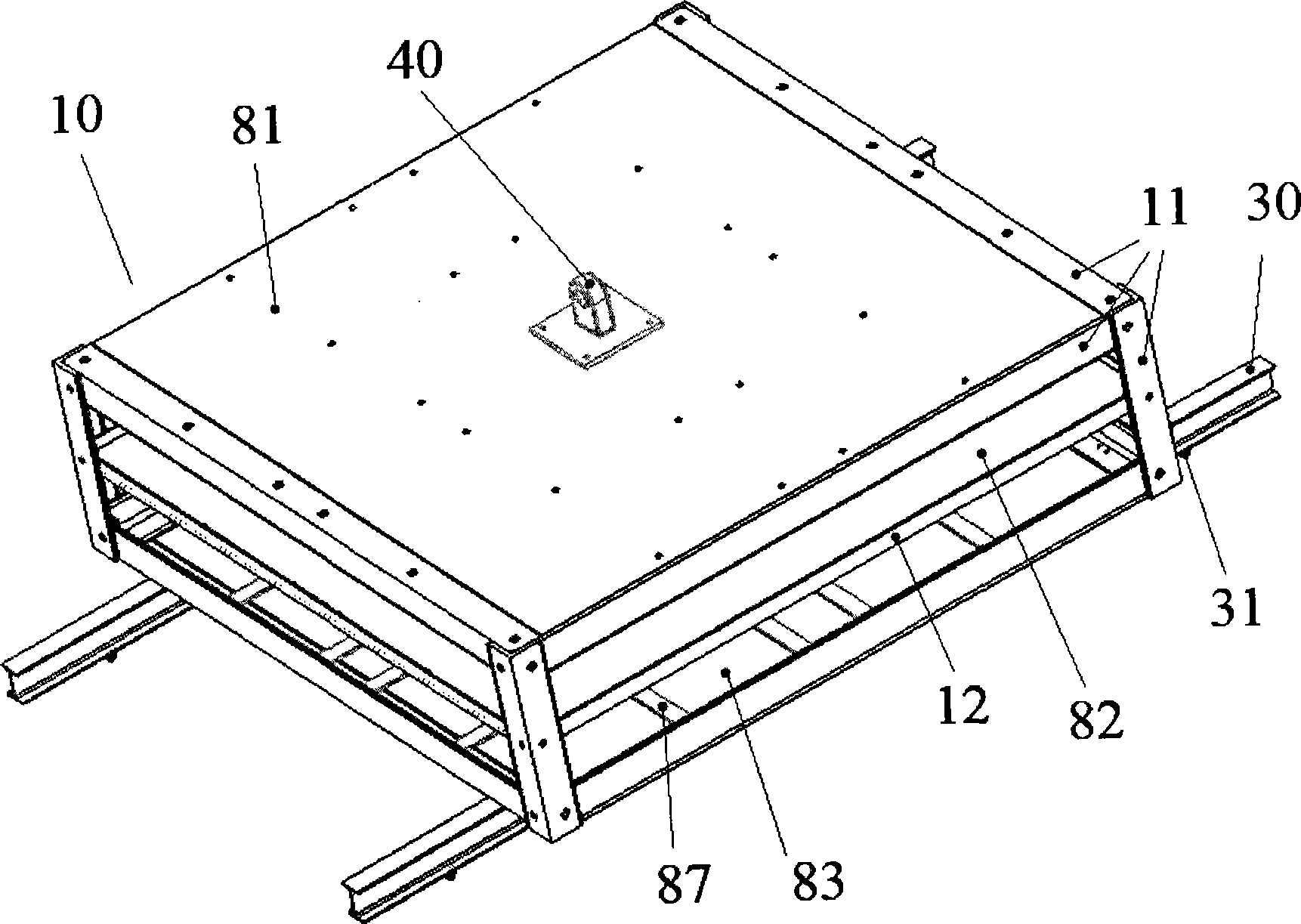

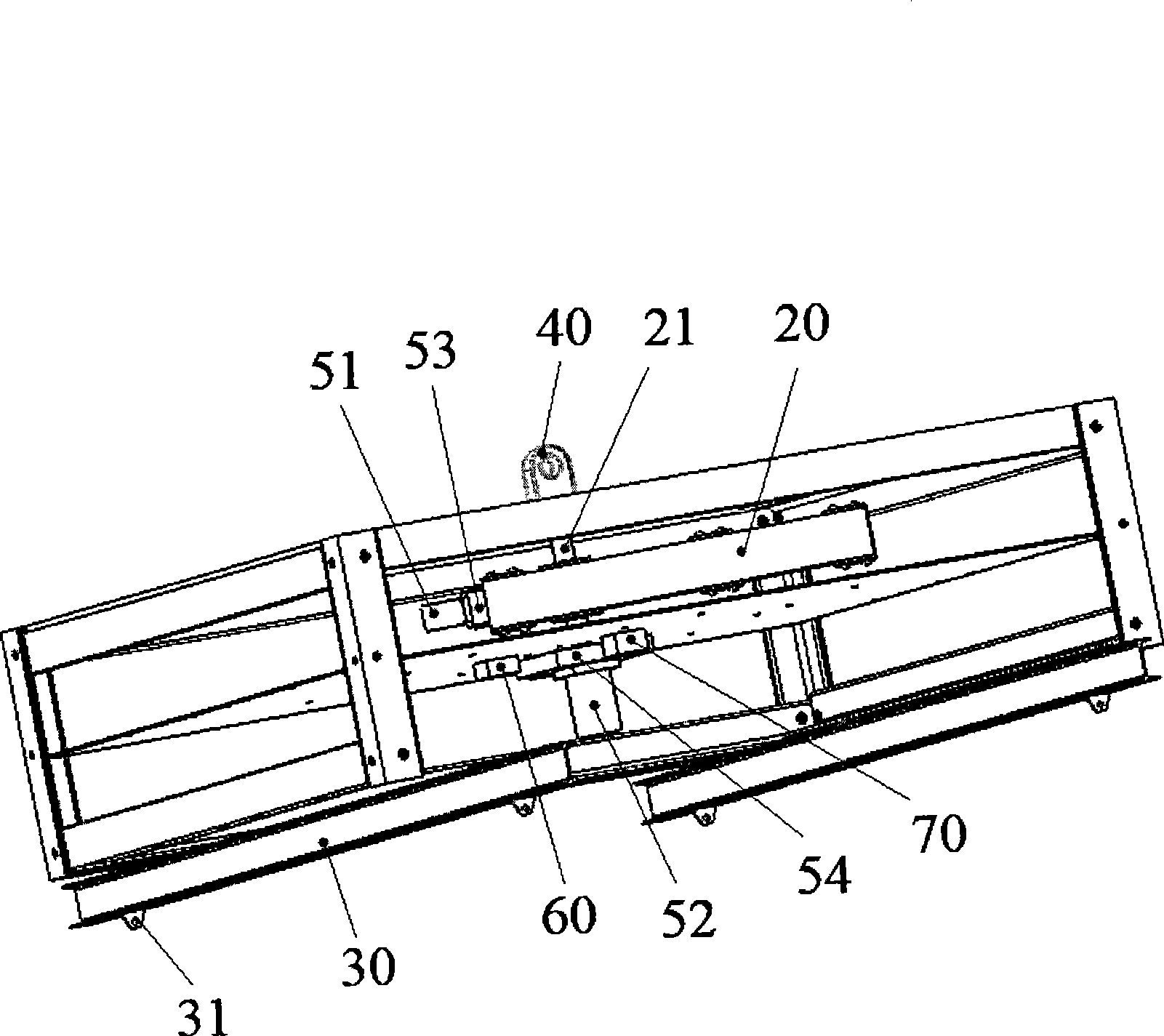

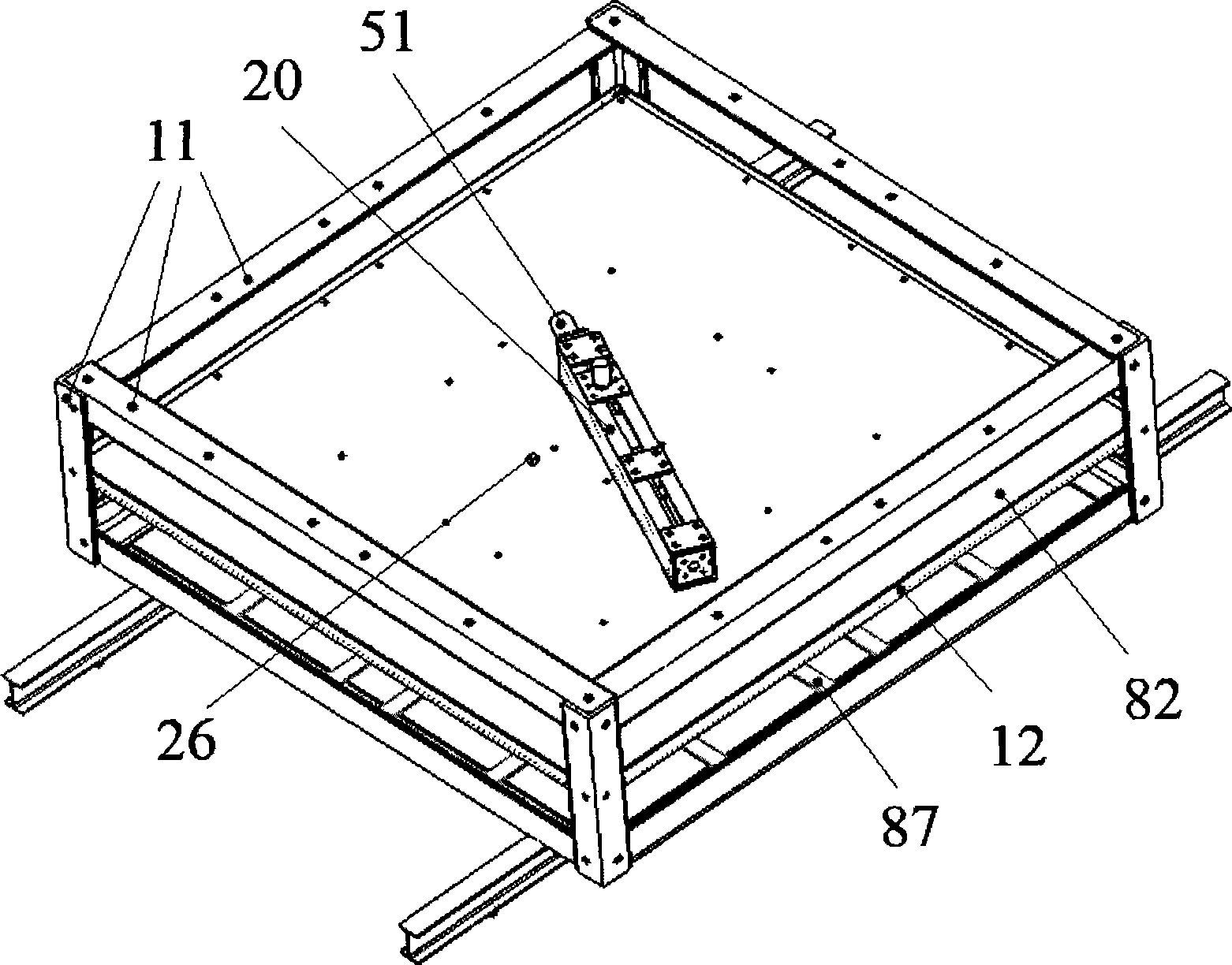

[0053] In order to use the method of center of gravity compensation to compensate the eccentric moment caused by the eccentric load, the present invention designs such figure 1 Self-levelling spreader system shown in polar coordinates. The main part of the whole system is a load-bearing box 10, which consists of a box load-bearing beam 11 supporting the upper surface plate 81, a box body load-bearing beam 11 supporting the lower surface plate 83, and a box body load-bearing beam connecting the upper and lower surfaces. 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com