Resin forming optical lens

An optical lens and resin molding technology, applied in optics, lenses, optical components, etc., can solve problems that are difficult to realize, hinder application and introduction, and achieve the effect of simplifying the assembly process and reducing the concentration loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

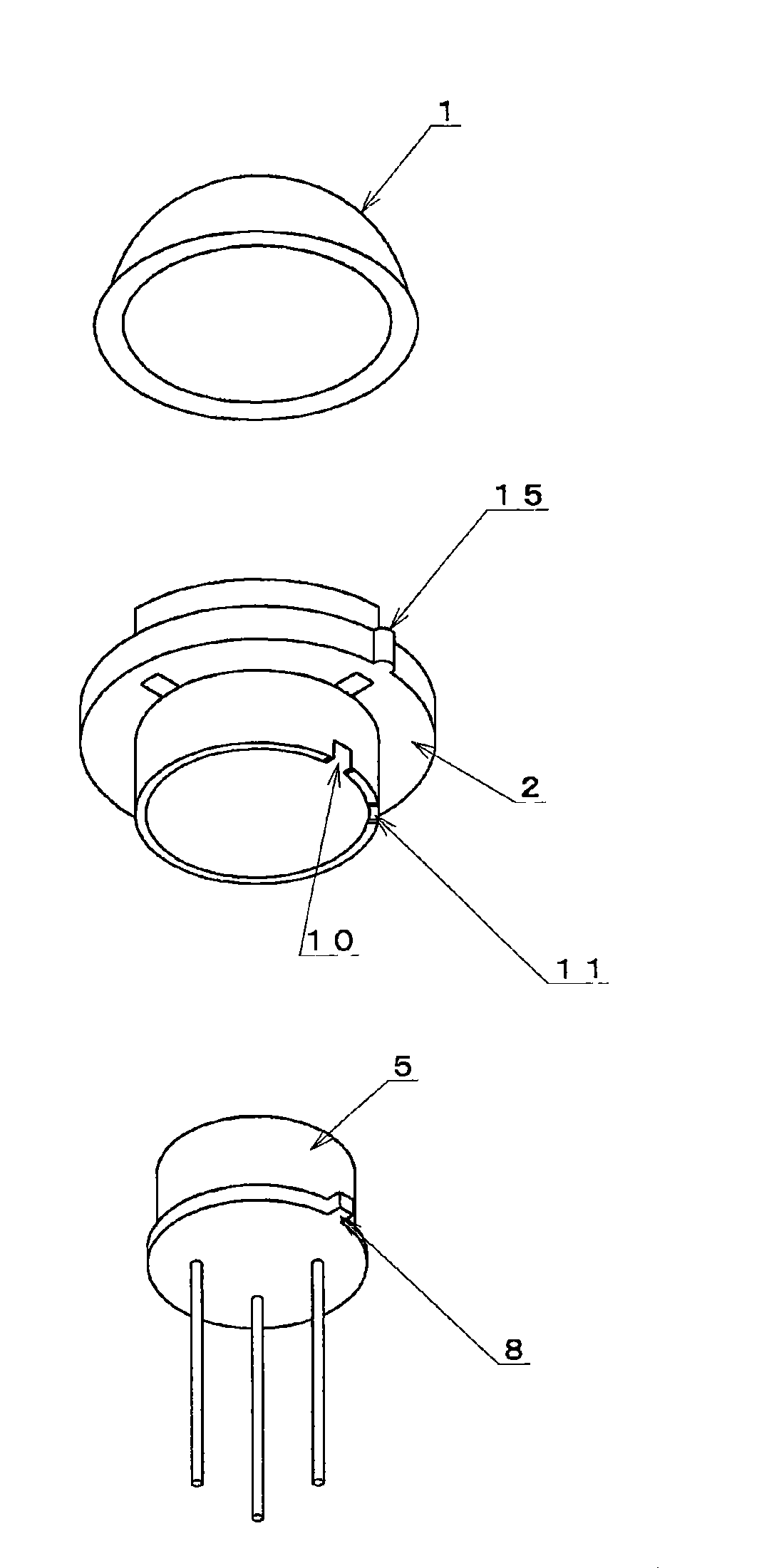

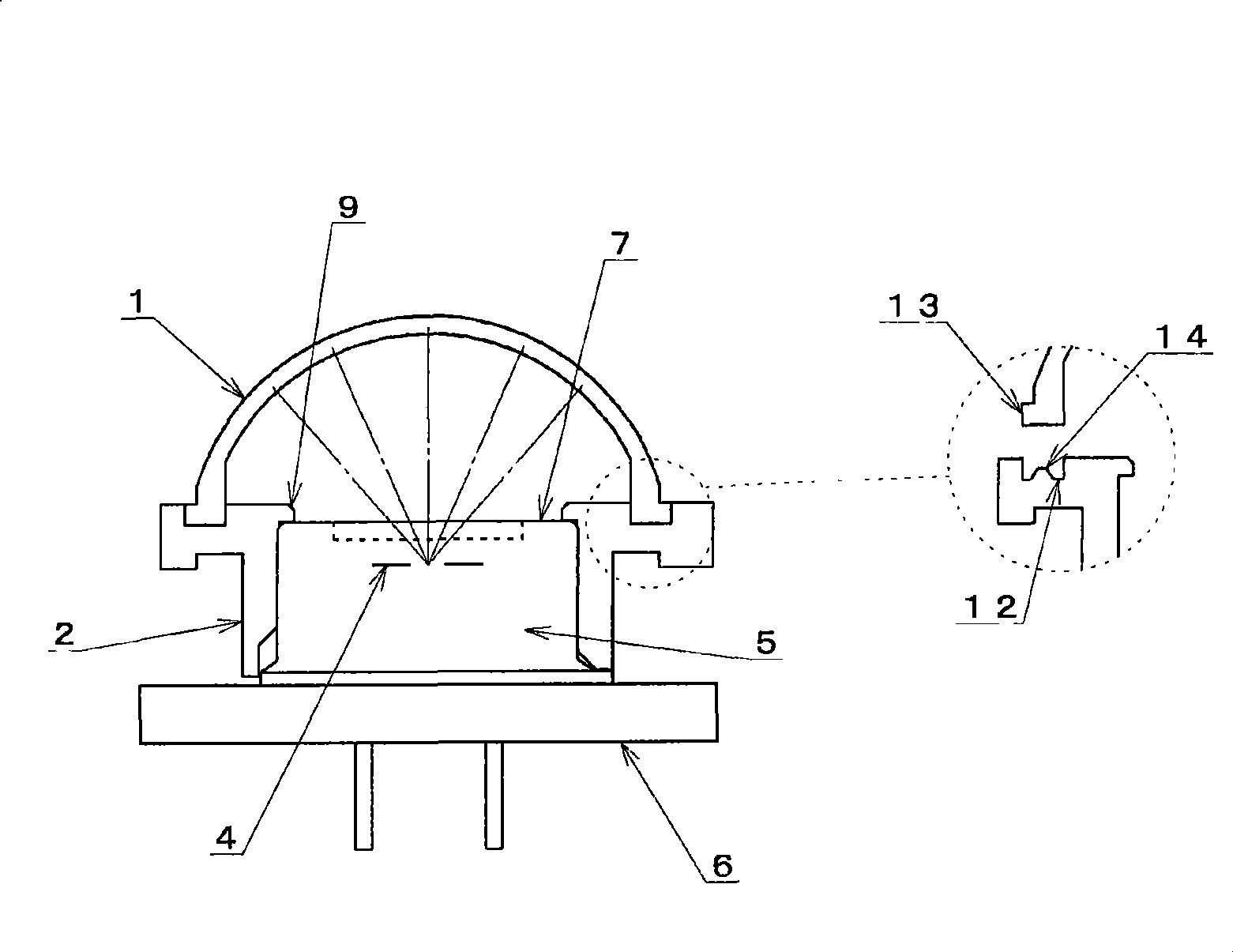

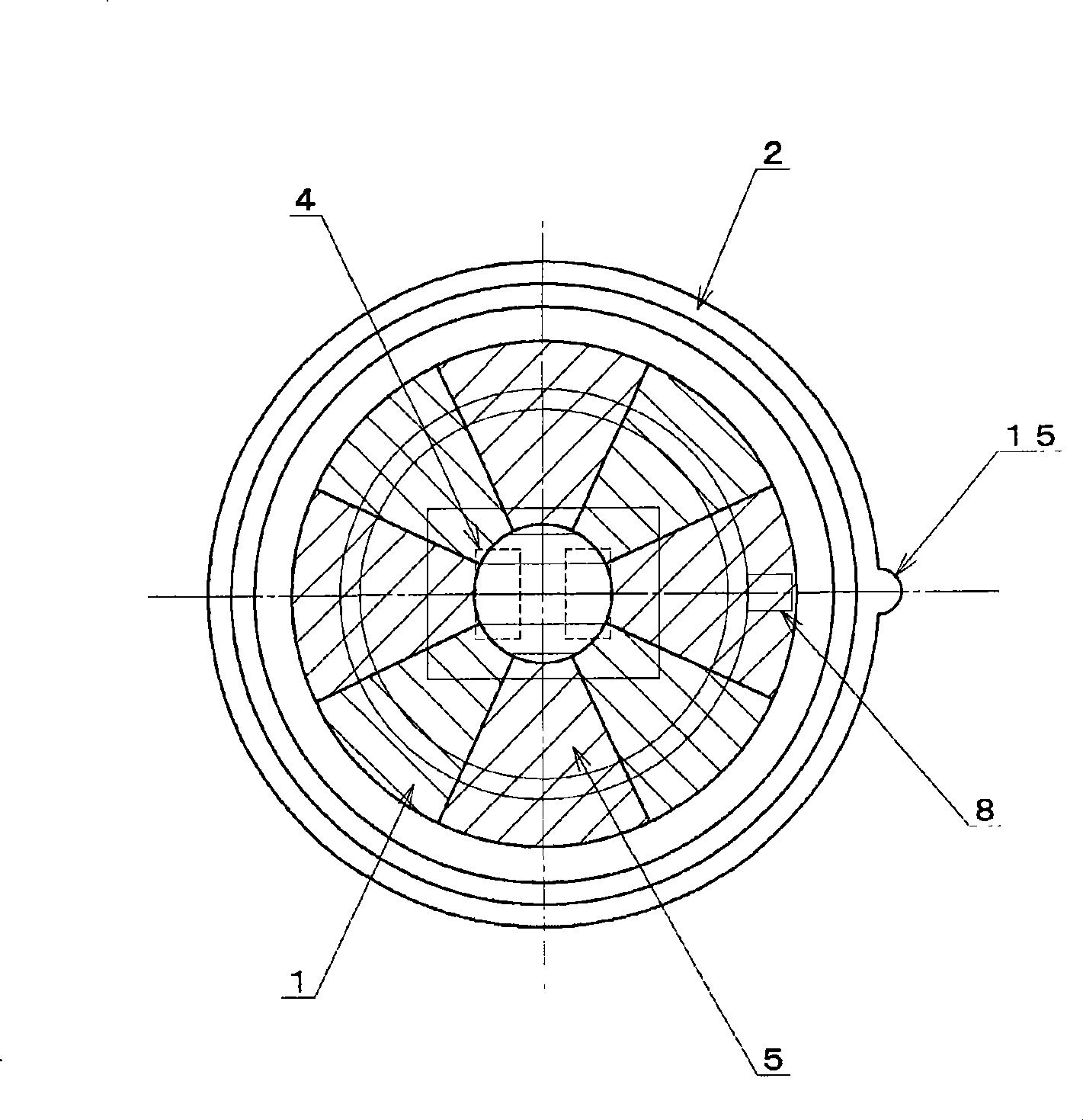

[0032] First refer to figure 1 and figure 2 , which relates to the resin molded optical lens of the present invention in detail. In the first embodiment, an optical lens that can be attached to a TO-5 pyroelectric infrared detector is taken as an example. The condensing lens 1 provided on the upper side is a thin-walled spherical lens that divides the infrared detection area into nine parts, and each lens part is made of a Fresnel shape. The focal distance relationship between each lens and the infrared light receiving element 4 is kept at 6.5mm±0.2mm, the spherical radius of the lens is designed to be 6.7mm±0.2mm. Installed to the lower side support part 2 on the TO-5 type pyroelectric infrared detector 5, the top of the detector case 7 and the detector TAB8 become installation suppression points, and the suppression part 9 on the inner surface side of the above-mentioned support part 2 and the bottom part Two support points 10 and 11 punched along the detector TAB8 are ...

Embodiment 2

[0038] use Figure 5 and Figure 6 , the mode of the invention related to the second embodiment will be described. Figure 5 Indicates that the optical lens used in Example 1 is oriented in the direction in which the second support point 11 of the lower support part 2 coincides with the detector TAB8, that is, the light distribution optical axis between the infrared light receiving element 4 and each lens part is relative to the regular reference axis The above perspective outline when rotated 45 degrees, Figure 6 express Figure 5 In the infrared detection device with Figure 4 The projected infrared detection area at a distance of 5m from the detection object set under the same conditions. At this time, as the optical axis of the lens unit changes, the size, shape, light distribution and Figure 4 Unlike the infrared detection area shown, the projected shape of the infrared detection area is a quadrilateral with a maximum width of 9.4m in the X direction and a maximum ...

Embodiment 3

[0040] Figure 7 Indicates a thin-walled spherical shape in which a Fresnel-shaped lens assembly with a focus distance of 5.8 mm ± 0.2 mm and an infrared detection area divided into 7 parts is formed and placed at a position with a spherical radius of 6 mm ± 0.2 mm. After the lens is assembled to the lower side support part used in Example 1 and Example 2, it is ultrasonically welded and installed in the infrared detection device installed on the dual type infrared detector 5 and Figure 4 and Figure 6 The infrared detection area where the detection object is 5m away from the detection object under the same setting conditions. The infrared detection region formed by the above-mentioned seven-divided optical lens is formed in a cross shape with a maximum width of 9.1 m in the X direction and a maximum width of 9.0 m in the Y direction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com