Flow path control method for material handling system of stock yard

A conveying system and process control technology, applied in the direction of electrical program control, sequence/logic controller program control, etc., can solve the problems of less process, less equipment, more manpower and funds, etc., to save investment and shorten software development the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

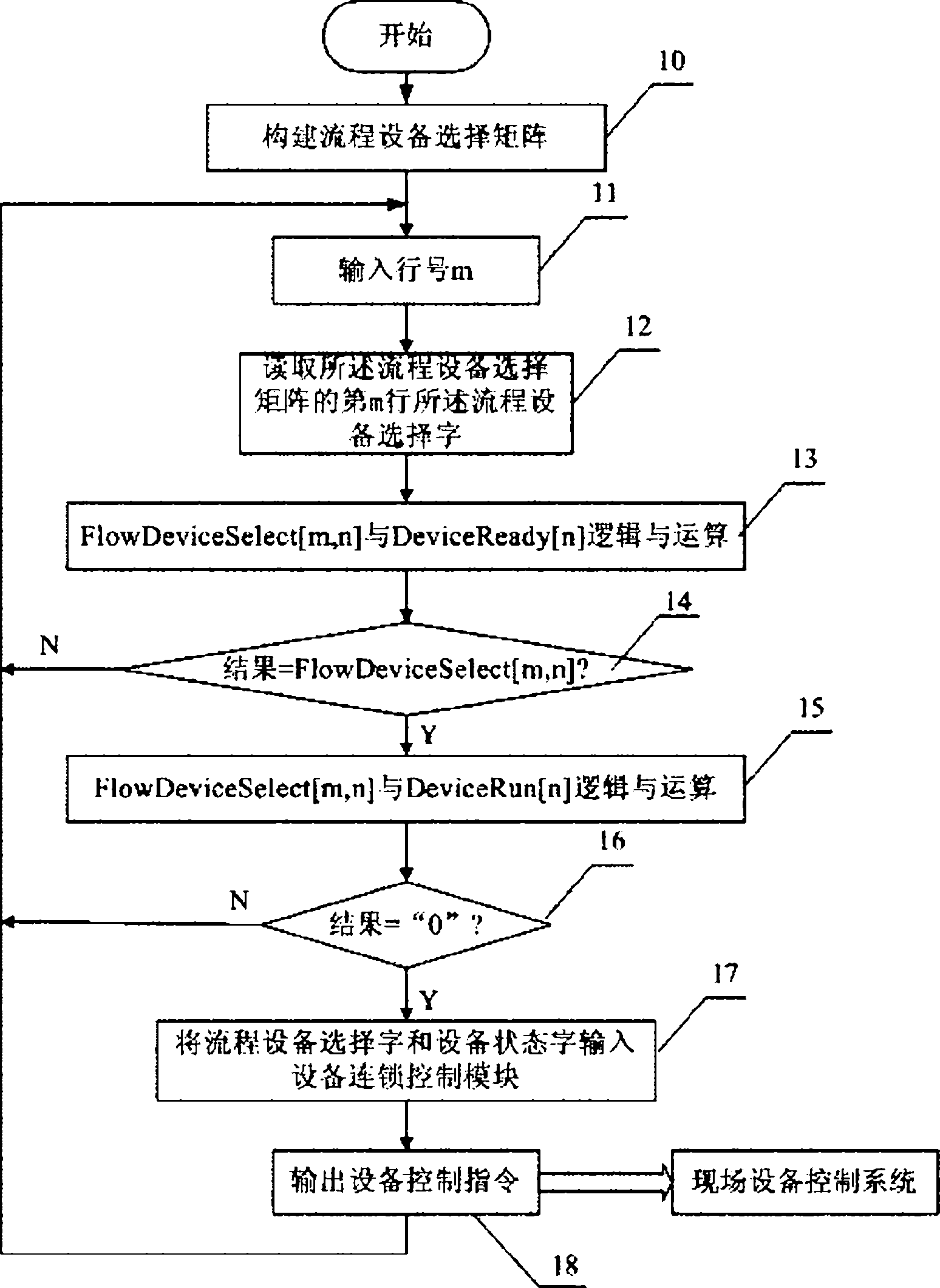

[0018] Such as figure 1 As shown, the system starts and enters step 10 to build a two-dimensional process device selection matrix FlowDeviceSelect[m, n] to store the selection relationship between processes and devices. The row number m of the matrix is used as the process number, and the column number n is used to identify the device , for example, FlowDeviceSelect[21, 30]=1 means that the No. 21 process selects the No. 30 device.

[0019] Go to step 11 and enter the process number m;

[0020] Enter step 12, read the process equipment selection word in the mth row of the process equipment selection matrix,

[0021] Step 13, use matrix logic operation to deal with the interlocking relationship between the processes, and perform the logic "AND" operation of the flow device selection word FlowDeviceSelect[m, n] and the device status word DeviceReady[n],

[0022] Step 14, judge whether the result is equal to FlowDeviceSelectm, n], if not in step 14, return to step 11.

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com