Printed circuit board and making method thereof

A technology of printed circuit board and manufacturing method, which is applied in the manufacture of multilayer circuits, printed circuits connected with non-printed electrical components, optical waveguides and light guides, etc., can solve problems such as affecting the performance of optical fibers and achieve the effect of preventing the impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

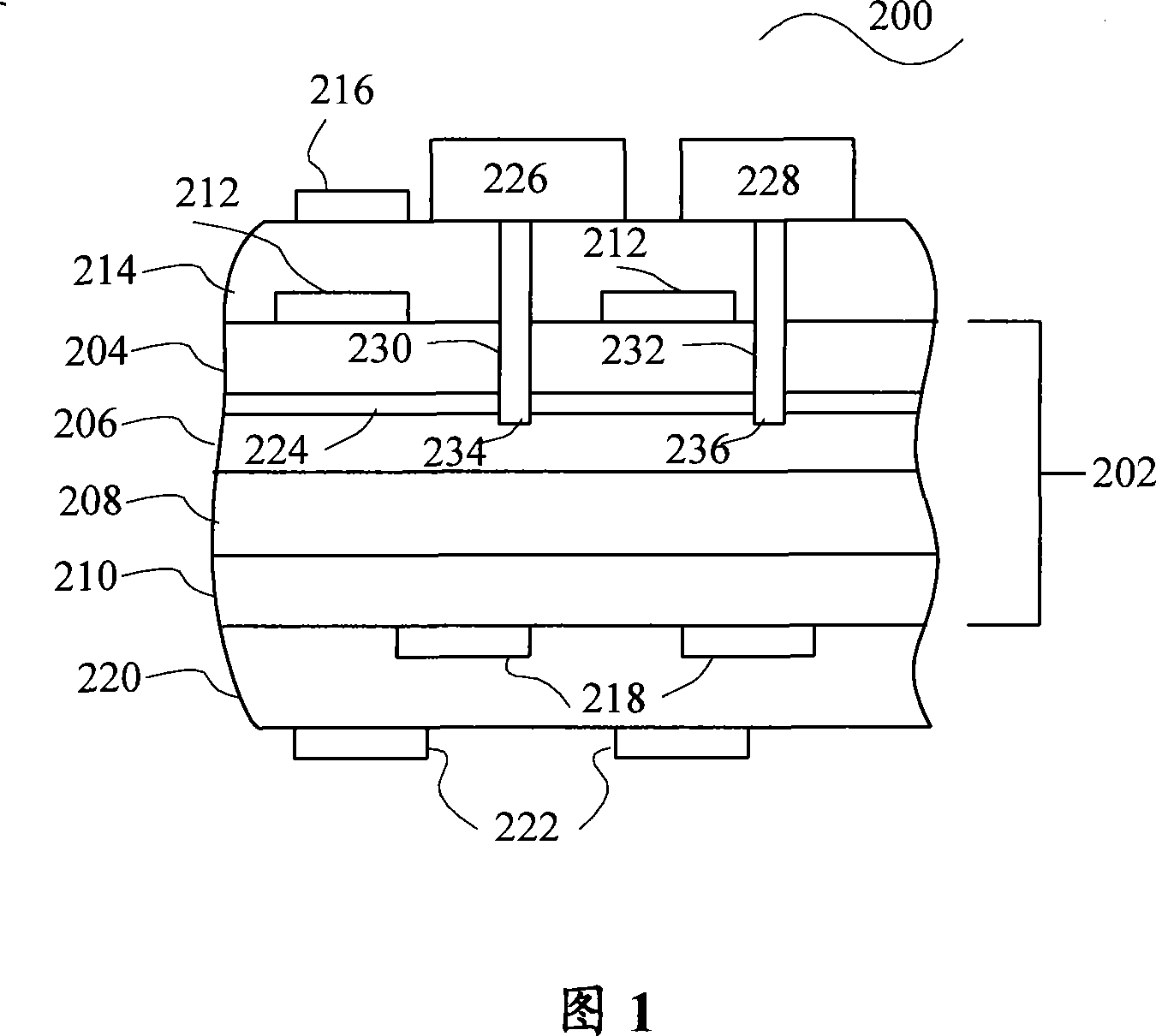

[0054] The invention embeds an optical channel structure in the stacked layer formed by stacking printed circuit board matrix boards, and implants optical fibers for optical interconnection after the printed circuit board manufacturing process is completed, preventing the printed circuit board manufacturing process from affecting the optical fiber performance.

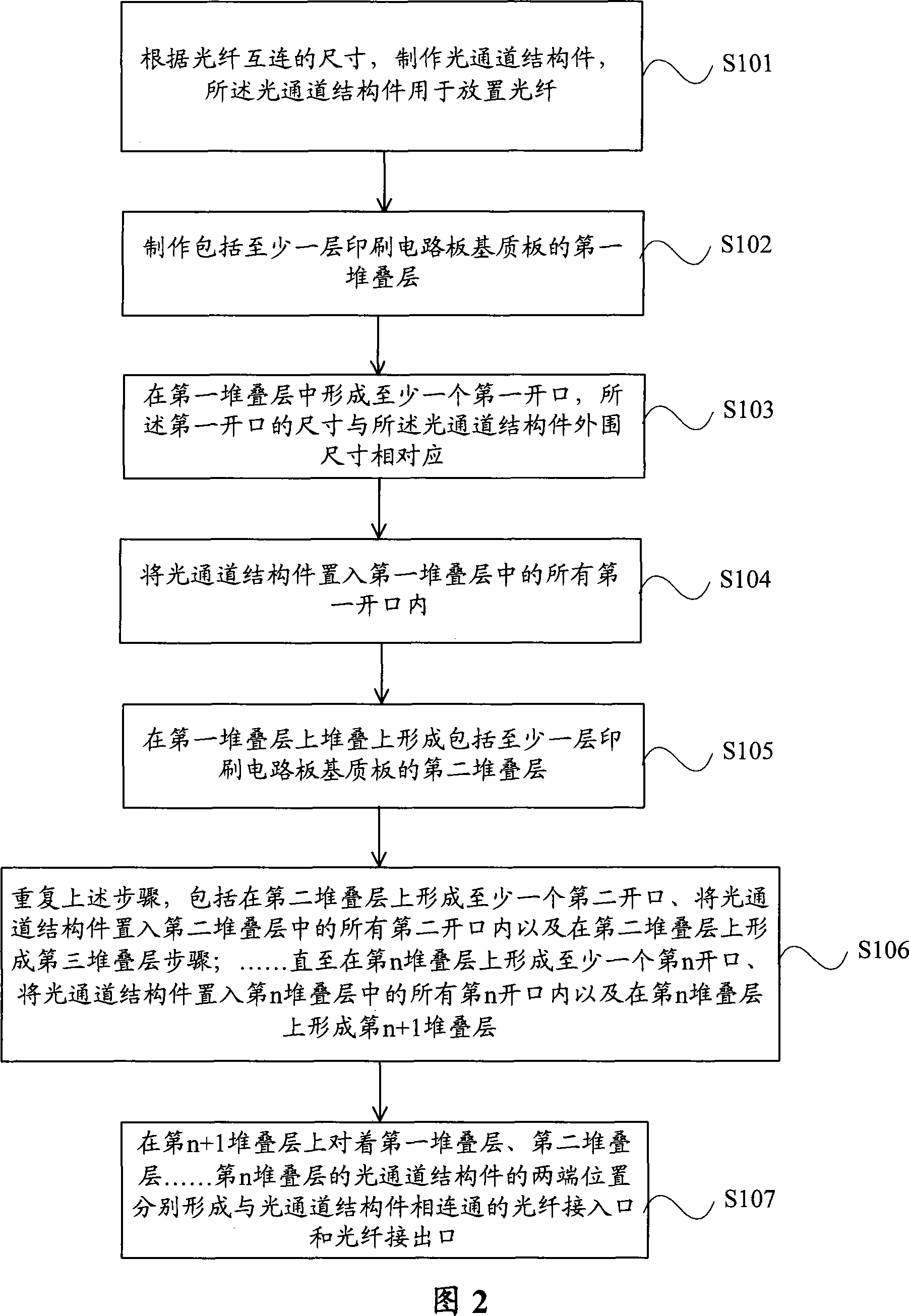

[0055] Referring to FIG. 2 , the present invention provides a schematic flow chart of a specific embodiment of a printed circuit board, including the following steps: performing step S101, making a hollow and sealed optical channel structure of at least one size according to the size of the optical fiber interconnection, The optical channel structure is used for built-in optical fibers; step S102 is performed to manufacture a first stacked layer including at least one printed circuit board substrate board; step S103 is performed to form at least one first opening in the first stacked layer, the The size of the first ope...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com