Form seal, seal arrangement and process sensor with such a sealing arrangement

A technology of sealing body and sealing surface, applied in the field of process sensors, which can solve the problems of restriction, sealing ring leakage, complex structure and/or installation steps, etc., and achieve the effect of eliminating shortcomings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

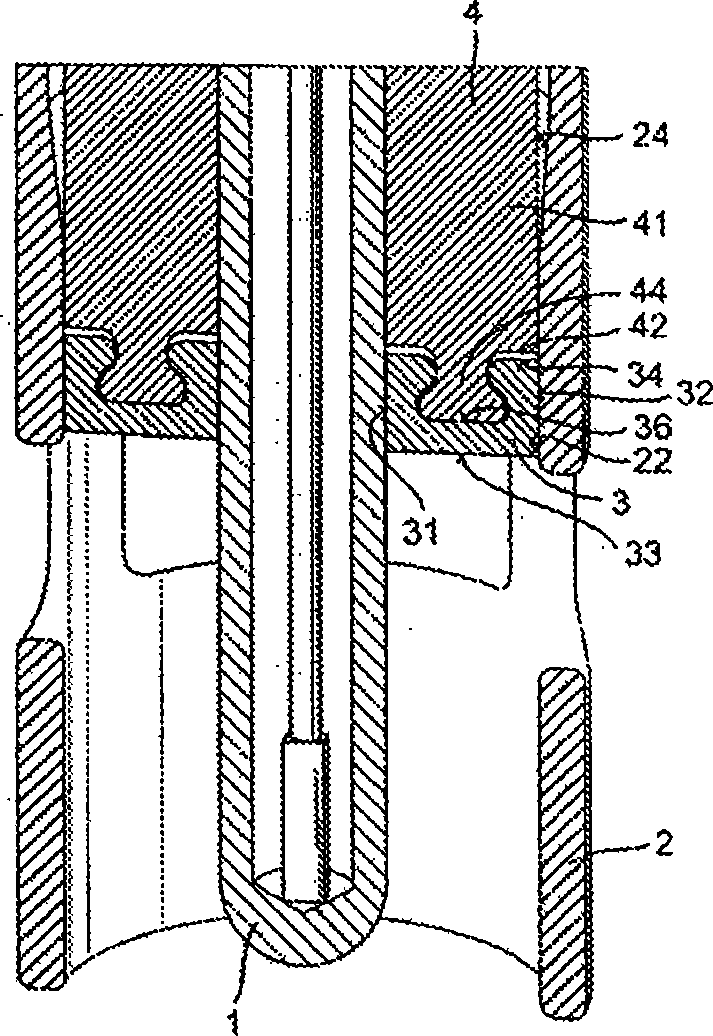

[0049] figure 1The conductivity sensor shown in comprises an inner electrode 1 and an outer electrode 2 which are separated from each other by a shaped seal 3 and a sealing support 4 and are sealed relative to each other. The outer diameter of the inner electrode is for example about 5 mm and the inner diameter of the first axial portion 22 of the outer electrode in which the shaped seal 3 is arranged is for example about 14.25 mm. At least at the ends in contact with the medium, the two electrodes preferably have electrolytically polished stainless steel surfaces with a roughness not greater than 0.4 mm.

[0050] The sealing body of the shaped seal 3 has a radially inner sealing surface 31 , which adjoins the inner electrode 1 without gaps, and a radially outer sealing surface 32 , which adjoins the outer electrode without gaps. The sealing surfaces are connected to each other by a substantially planar top surface 33 . The top surface 33 axially delimits the measuring chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com