Structure plywood plate for timber-construction and production method thereof

A technology for plywood and construction, which is used in the joining of wooden veneers, chemical instruments and methods, and layered products, etc., can solve the problems of high production costs, application limitations, and high plywood density, and achieves lower production costs and lower costs. The effect of construction cost and high mechanical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

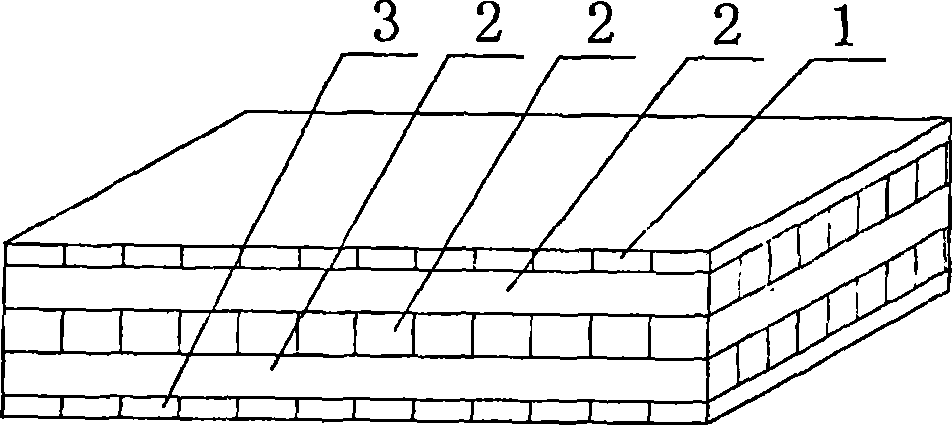

[0045] Structural plywood for five-ply poplar timber structures

[0046] Such as figure 1 As shown, the surface board 1 and the back board 5 of the structural plywood for the wooden structure are poplar veneers of about 1.5 mm, and the middle three core boards 2 are all poplar veneers of 3.0 mm, and the lines between the five veneers Formed into criss-cross blanks, the thickness of the processed plywood is 9 mm, and the veneer is processed by drying, forming, gluing, cold pressing, aging, and hot pressing. The specific production steps are as follows:

[0047] Log sawing: sawing poplar logs into wood sections according to the required size;

[0048] Log rotary cutting: peel poplar logs into 1.5 mm thick surface veneer, back veneer, and 3.0 mm core veneer;

[0049] Drying: Dry the rotary-cut veneer with drying equipment, so that the moisture content of the dried veneer is as follows: the moisture content of the core veneer should be about 8%, and the moisture content of the ...

Embodiment 2

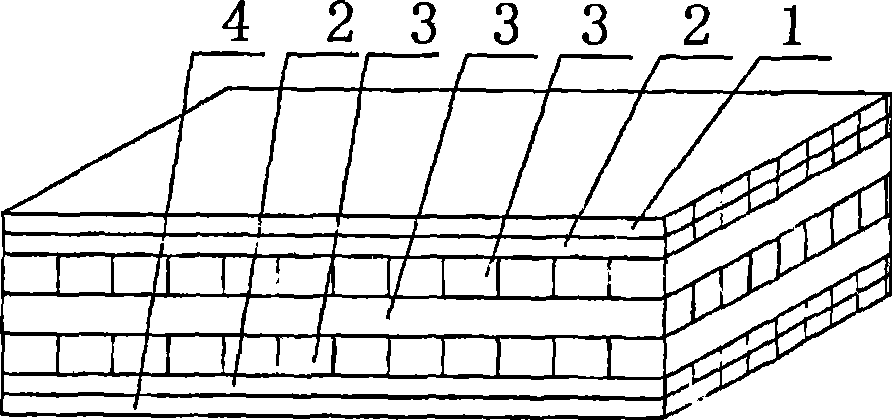

[0060] Structural plywood for seven-layer eucalyptus poplar composite wood structure

[0061] Such as figure 2 As shown, in the blank of the structural plywood for wood structure, the surface board and the back board are respectively composed of two layers of veneers, that is, the surface veneer 1 and the back layer veneer 4 are poplar veneers of 1.8 mm, and the subsurface The veneer 2 is a 1.5 mm domestic eucalyptus veneer, and the middle three layers are a 3.5 mm poplar core veneer 3 . Among them, the surface veneer 1 and the adjacent subsurface eucalyptus veneer 2, the back layer veneer 4 and the adjacent subsurface eucalyptus veneer 2 are respectively arranged in parallel grains, and then connected with the remaining three-layer core veneer 3 The blanks are assembled in a criss-cross arrangement of lines, and the thickness of the processed plywood is 15 mm. Concrete production method steps are as follows:

[0062] Log sawing: saw poplar and eucalyptus logs into wood se...

Embodiment 3

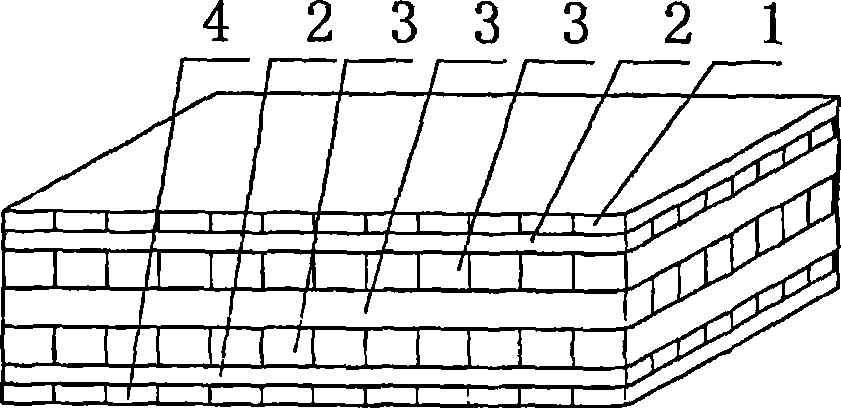

[0075] Structural plywood for seven-layer pine-poplar composite wood structure

[0076] Such as image 3 As shown, in the blank of the structural plywood for wood structure, the front panel and the back panel are composed of two layers of veneers respectively, that is, the surface veneer 1, the back veneer 4 and the subsurface 2 are 2.0mm domestic larch veneer, the middle three layers are 4.0 mm poplar core veneer 3. Among them, the veneers of each layer are assembled in a criss-cross arrangement of lines, and the thickness of the processed plywood is 18 mm. Concrete production method steps are as follows:

[0077] Log sawing: saw poplar and larch logs into wood sections according to the required size;

[0078] Log rotary cutting: Rotate poplar logs into poplar veneers with a thickness of 4.0 mm; rotate larch logs into larch veneers with a thickness of 2.0 mm;

[0079] Drying: Dry the rotary-cut veneer with drying equipment. The moisture content of the dried veneer is as f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com