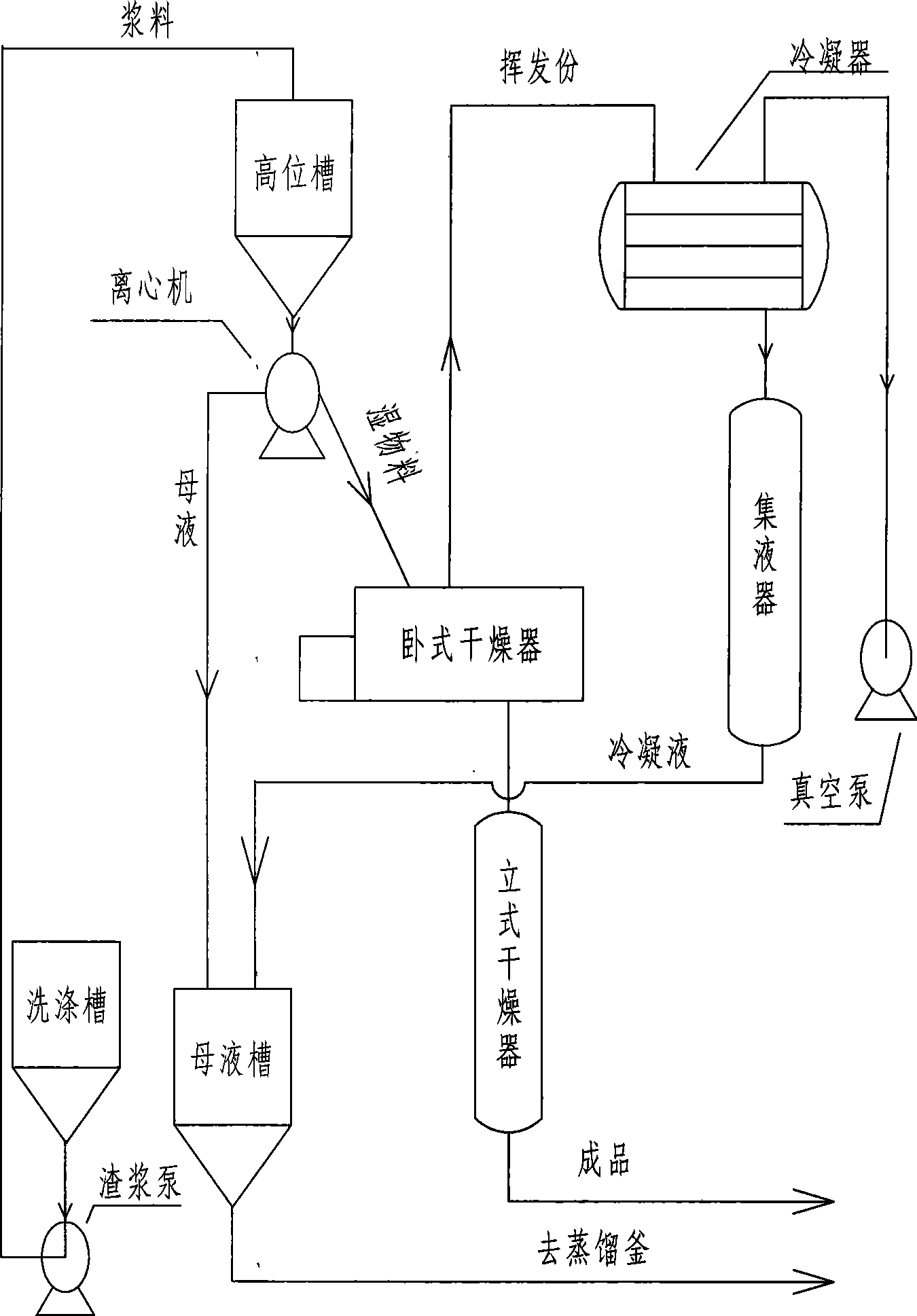

Desolution, centrifugation and drying integrated process of poly (propylene carbonate) industrial production

A polypropylene carbonate and drying technology, which is applied in the chemical industry, sustainable manufacturing/processing, climate sustainability, etc., can solve the problems of no detailed public reports on the process, and solve industrialization problems, production costs and labor costs. The effect of low cost and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The washing tank is sealed, and the inside is a slurry of polypropylene carbonate desolvated three times with methanol. Use a slurry pump to continuously drive the polypropylene carbonate slurry into the sealed high-level tank, and enter the centrifuge from the high-level tank. The slurry can be continuously entered into the centrifuge for centrifugation, so that the moisture content (weight) of the wet material < 50%; the mesh of the centrifuge filter is 50-300 mesh, and the wet material coming out of the centrifuge enters a horizontal dryer with a vacuum degree of 0-0.08MPa to dry for 1-6 hours, and the mother liquor enters the mother liquor tank; The wet material of the type dryer is dried with a moisture content (weight) < 1%, and the volatile matter is condensed and recovered into the mother liquor tank; the solids with a moisture content (weight) < 1% from the horizontal dryer continue to enter the vacuum Dry in a vertical dryer with a pressure of 0-0.08MPa for 1-...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap