Industrial preparation method of 1-naphthylamine

A technology of naphthylamine and catalyst is applied in the field of preparation of 1-naphthylamine, which can solve the problems of complicated catalyst preparation method, and achieve the effects of saving energy, low processing cost and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

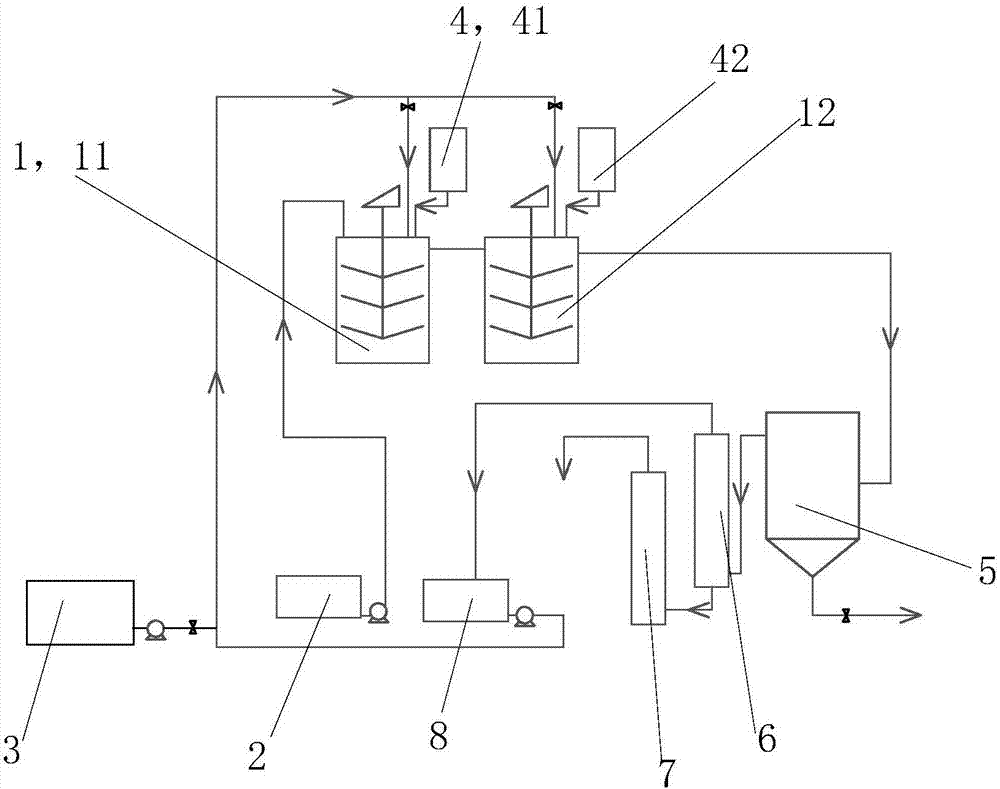

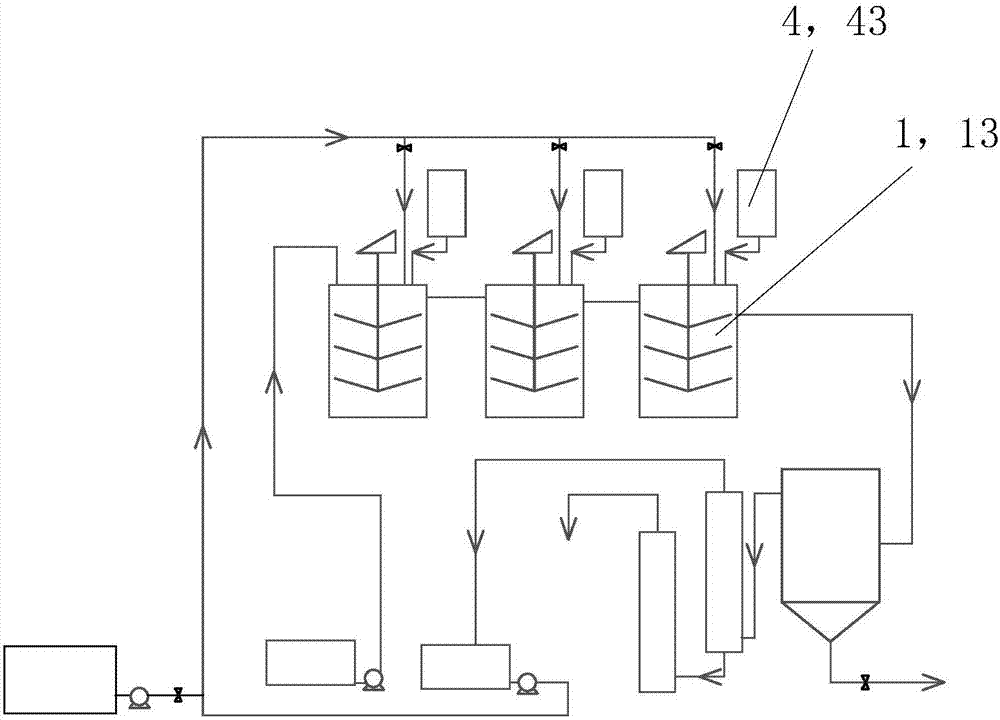

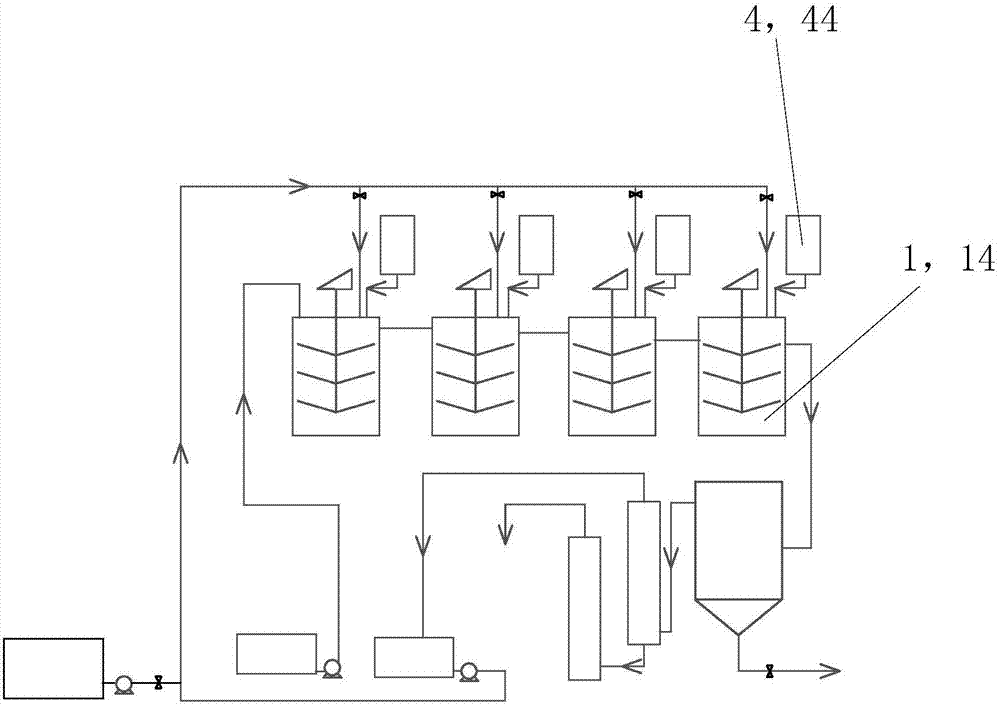

[0033] See figure 1 The device used in the industrialized preparation method of 1-naphthylamine of the present embodiment comprises a catalytic hydrogenation kettle 1, a nitronaphthalene storage tank 2, a solvent storage tank 3, a catalyst supplement tank 4, a catalyst settling tank 5, and a desolventizer 6 , Distillation unit 7 and recovery solvent storage tank 8.

[0034] Described catalytic hydrogenation still 1 comprises the first catalytic hydrogenation still 11 and the second catalytic hydrogenation still 12 of the identical volume of series connection, nitronaphthalene storage tank 2 is positioned at the top with the first catalytic hydrogenation still 11 by pump and pipeline. The feed port is connected, and the pump used in this embodiment is a metering pump. The top of the body of the first catalytic hydrogenation kettle 11 is provided with a discharge opening, the top of the body of the second catalytic hydrogenation kettle 12 is provided with a feed port and a disc...

Embodiment 2)

[0052] All the other of the industrialized preparation method of 1-naphthylamine of the present embodiment are identical with embodiment 1, difference is:

[0053] Step 1. the solvent that feeds in catalytic hydrogenation tank 1 is ethanol, and step 5. obtains the 1-naphthylamine that purity is 96.5% through distillation process, and amino total value 99.37%, the yield of 1-naphthylamine (by nitro naphthalene) was 97.6%.

Embodiment 3)

[0055] All the other of the industrialized preparation method of 1-naphthylamine of the present embodiment are identical with embodiment 1, difference is:

[0056] 10m in step ① 3 Add 6000L of reaction solvent methanol into the first catalytic hydrogenation kettle 11 and the second catalytic hydrogenation kettle 12 respectively, and then open the switch of the catalyst replenishment tank 4 above each catalytic hydrogenation kettle 1 to feed the first catalytic hydrogenation kettle 11 Add Raney nickel 75kg respectively in the second catalytic hydrogenation kettle 12.

[0057] Step ③ Heat each reactor and keep the temperature in each reactor at 120°C.

[0058] Step ④ Under the condition of 120°C, continuously feed hydrogen into the first catalytic hydrogenation tank 11 and the second catalytic hydrogenation tank 12 until the internal pressure of each catalytic hydrogenation tank 1 is 1.3 Mpa, and keep each catalytic hydrogenation tank 1 The internal pressure is 1.3 MPa.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com