Control piston measurement and assembly system and method for variable-compression-ratio engine

A technology for controlling pistons and assembly systems, applied in engine control, measuring devices, machines/engines, etc., can solve problems such as errors in the system assembly process, manufacturing errors, etc., to improve operating efficiency, reduce labor intensity, and ensure installation quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

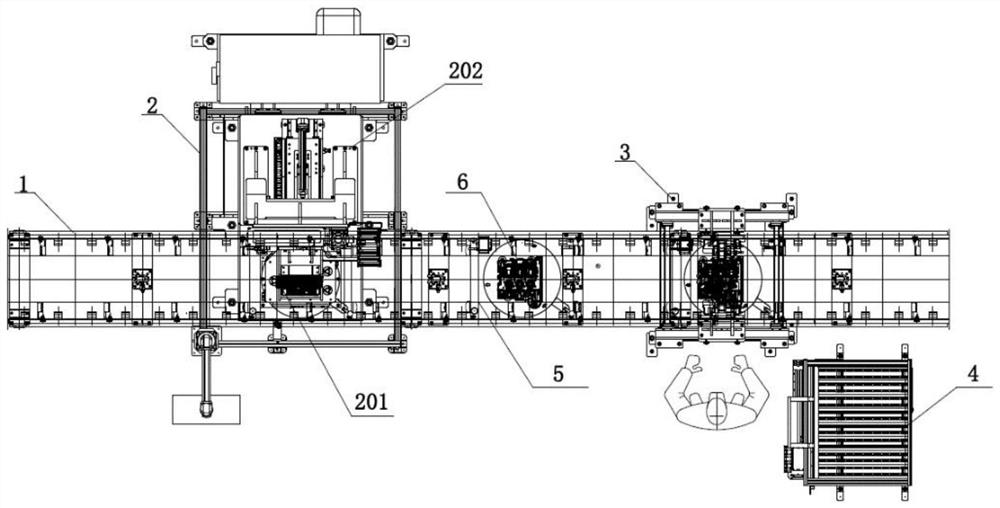

[0035] Please refer to Figure 1 to Figure 3 , this embodiment provides a control piston measurement and assembly system for a variable compression ratio engine, including an assembly line body 1, a measuring device 2 and an optional assembly device 3, and the variable compression ratio engine 6 moves along the assembly line body 1 and sequentially Via measuring device 2 and optional assembly device 3 .

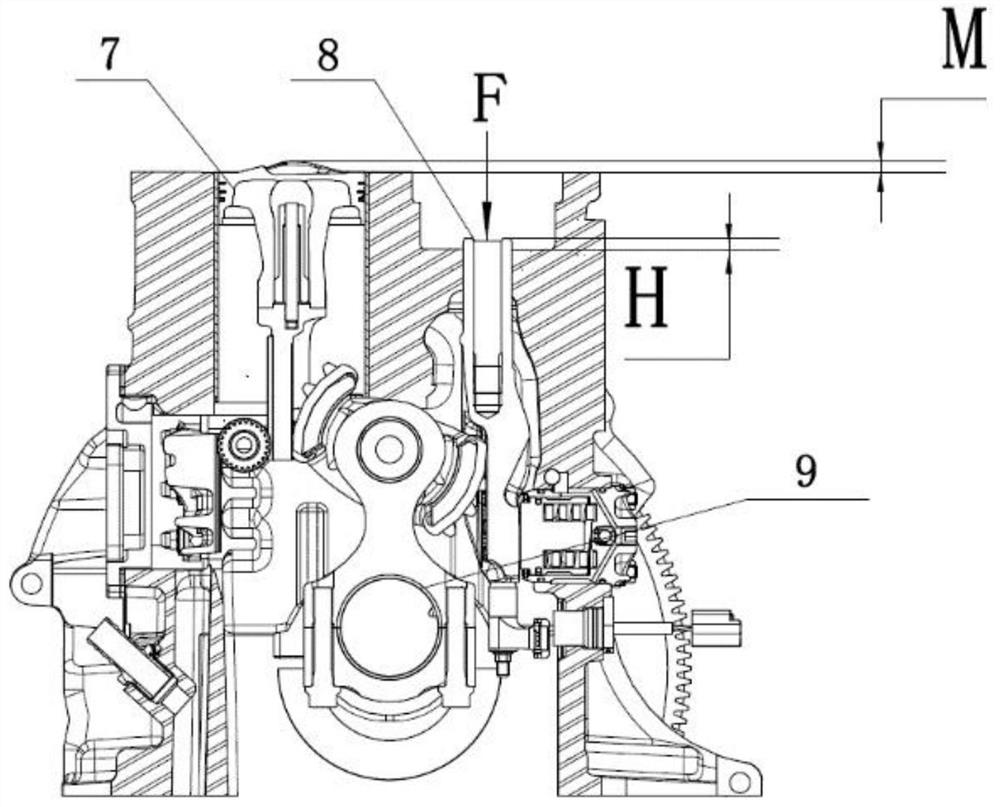

[0036] The variable compression ratio engine 6 has a control piston, a control tooth plate 8 and a control cylinder, the control piston is fixed to the rod portion of the control tooth plate 8, and the control cylinder is used to control the control piston. The control piston is fixedly connected with the control tooth plate 8, and the control piston is fixedly installed on the upper end of the control tooth plate. In the variable compression ratio engine 6, the engine also has a combustion piston, which is the main part of the combustion chamber. One side of the combustion ...

Embodiment 2

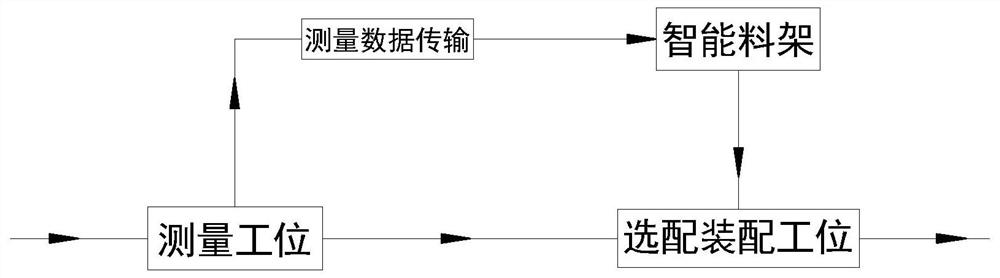

[0077] Based on the control piston measurement and assembly system for a variable compression ratio engine in Embodiment 1, this embodiment provides a control piston measurement and assembly method for a variable compression ratio engine, which can be referred to Figure 5 , this method includes the following steps:

[0078] The variable compression ratio engine 6 enters the measuring device 2 through the assembly line body 1;

[0079] Pre-rotate the crankshaft 9 of the variable compression ratio engine 6, and lock the crankshaft 9 phases;

[0080] Rotate the crankshaft 9 so that the control tooth plate 8 is in the bottom dead center state, and measure the distance H value between the top of the control tooth plate 8 and the bottom of the control cylinder;

[0081] Complete the H value measurement of all cylinders and obtain the measurement results;

[0082] The variable compression ratio engine 6 enters the optional assembly equipment 3 through the assembly line body 1, and...

Embodiment 3

[0086] Based on the control piston measurement and assembly system for a variable compression ratio engine in embodiment 1, and the control piston measurement and assembly method for a variable compression ratio engine in embodiment 2, this embodiment further improves the method and proposes a A control piston measurement and assembly method for a variable compression ratio engine, such as Figure 5 shown, including the following steps:

[0087] The variable compression ratio engine 6 follows the row tray 5 through the assembly line body 1 and enters the measurement station to which the measurement device 2 belongs, and the measurement starts;

[0088] The variable compression ratio engine 6 is lifted and positioned through the accompanying pallet 5;

[0089] The lifting and clamping mechanism 202 clamps down the cylinder block of the variable compression ratio engine 6;

[0090] Pre-rotate the crankshaft 9 of the variable compressor engine, and lock the crankshaft 9 phases;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com