Blast furnace temperature optimization control method

A technology for optimal control, blast furnace, applied in the field of information

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

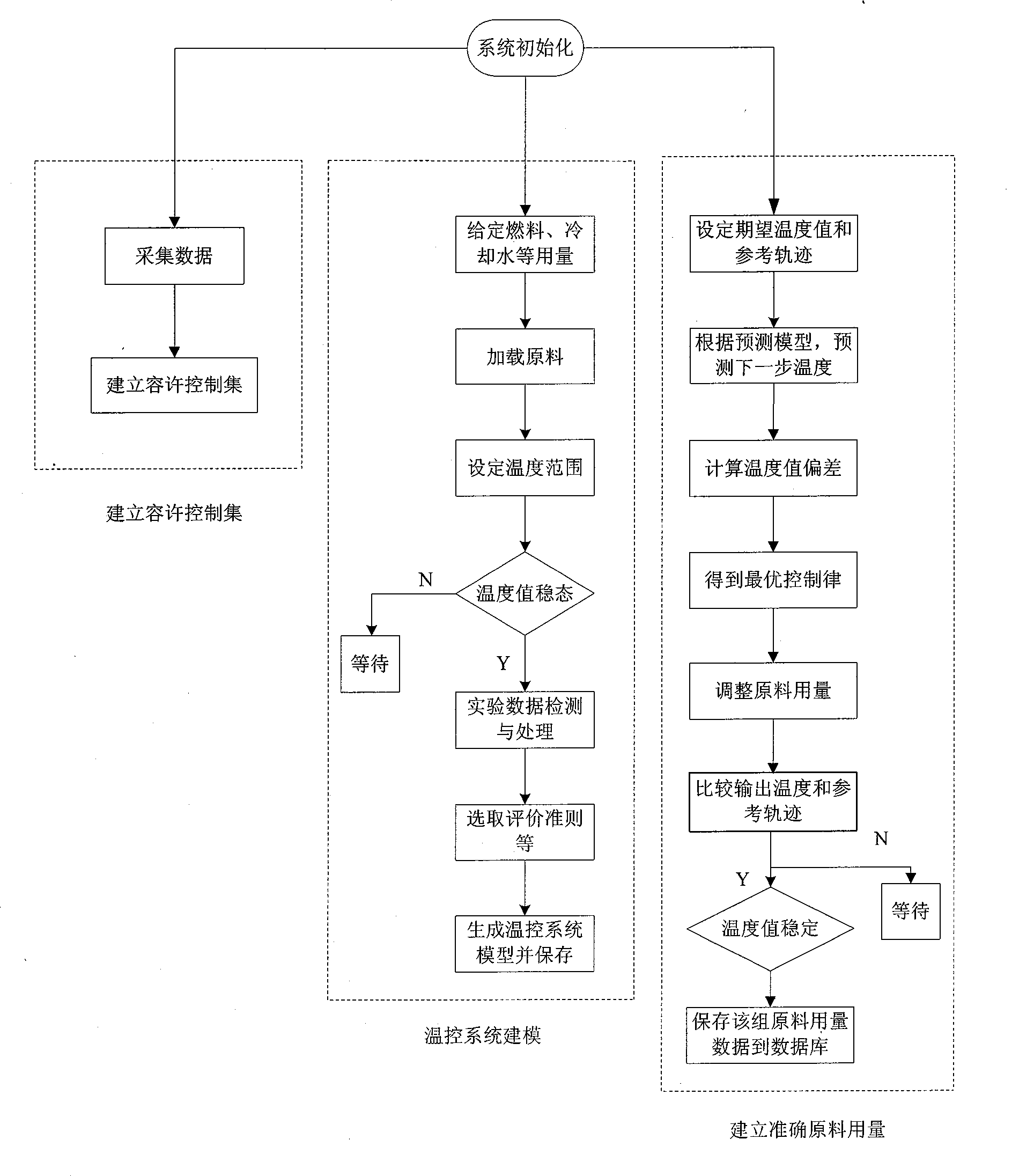

[0060] Such as figure 1 , the specific application steps of the blast furnace temperature optimization control method are as follows:

[0061] (1) Collect the parameters of the coal injection volume, blast volume and cooling water flow rate of the blast furnace temperature control operation, measure the uncertainty with the Euclidean space, and establish the allowable control set Ω:

[0062] Ω={ΔA i (k)∈R n×n , h(k)∈R, i=0, 1, 2|∥ΔA i (k)‖<∞,0

[0063] The establishment of the allowable control set is to ensure that there is a solution when calculating the optimal control rate in step (8).

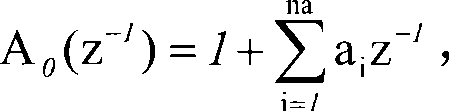

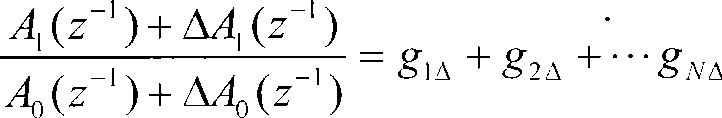

[0064] (2) Taking the coal injection rate, air blast rate and cooling water flow rate as the control input, and the temperature observed by the cross thermometer as the output value, within the range of the allowable control set Ω, establish a discrete difference method based on the least squares method. Determine the Controlled Autoregressive Moving Average Model (CARMA):

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com