Fan frame

A fan frame and fan technology, applied to parts of pumping devices for elastic fluids, non-variable pumps, machines/engines, etc., can solve problems such as operational troubles, increase production efficiency, and facilitate disassembly and assembly. The effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

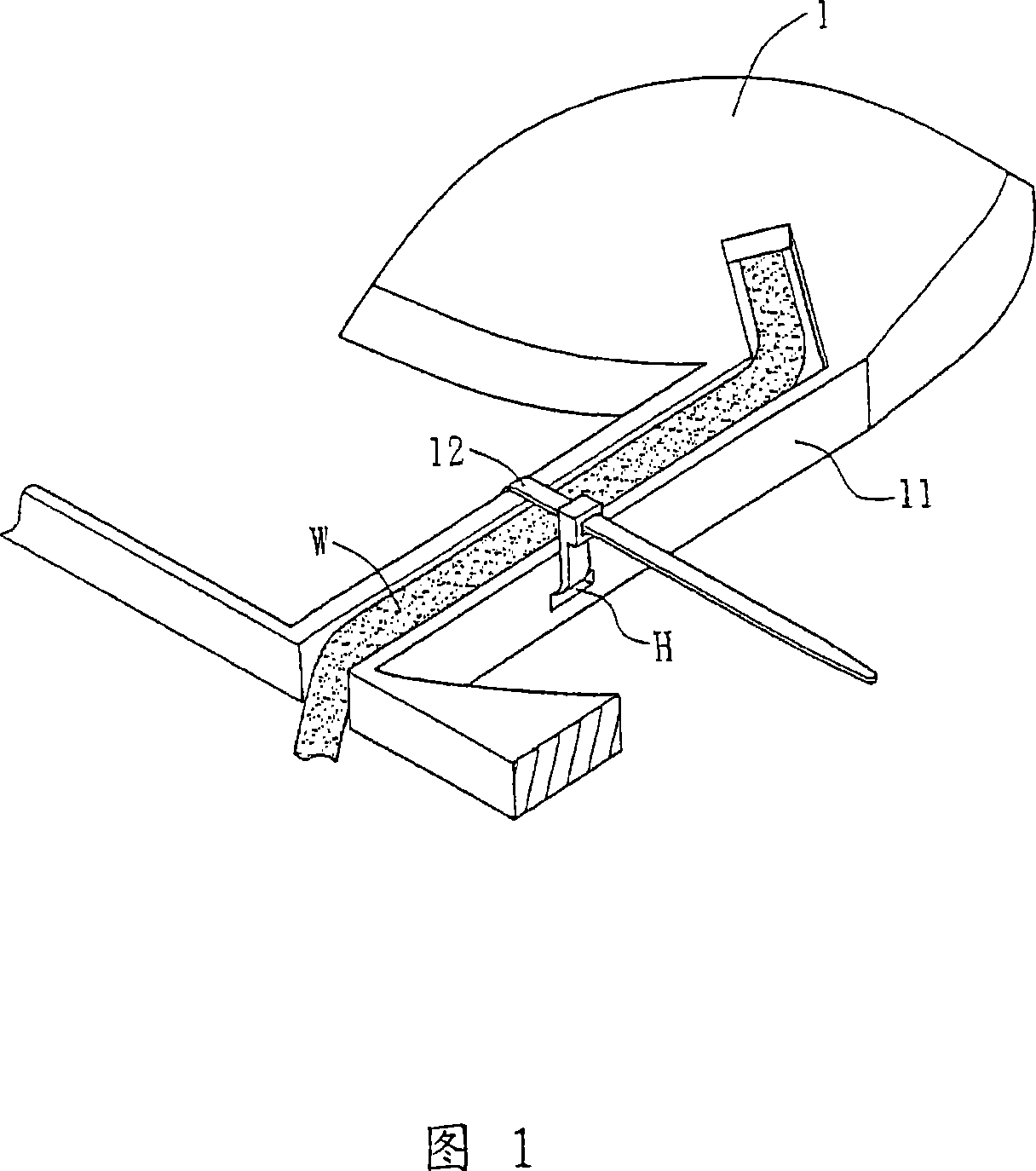

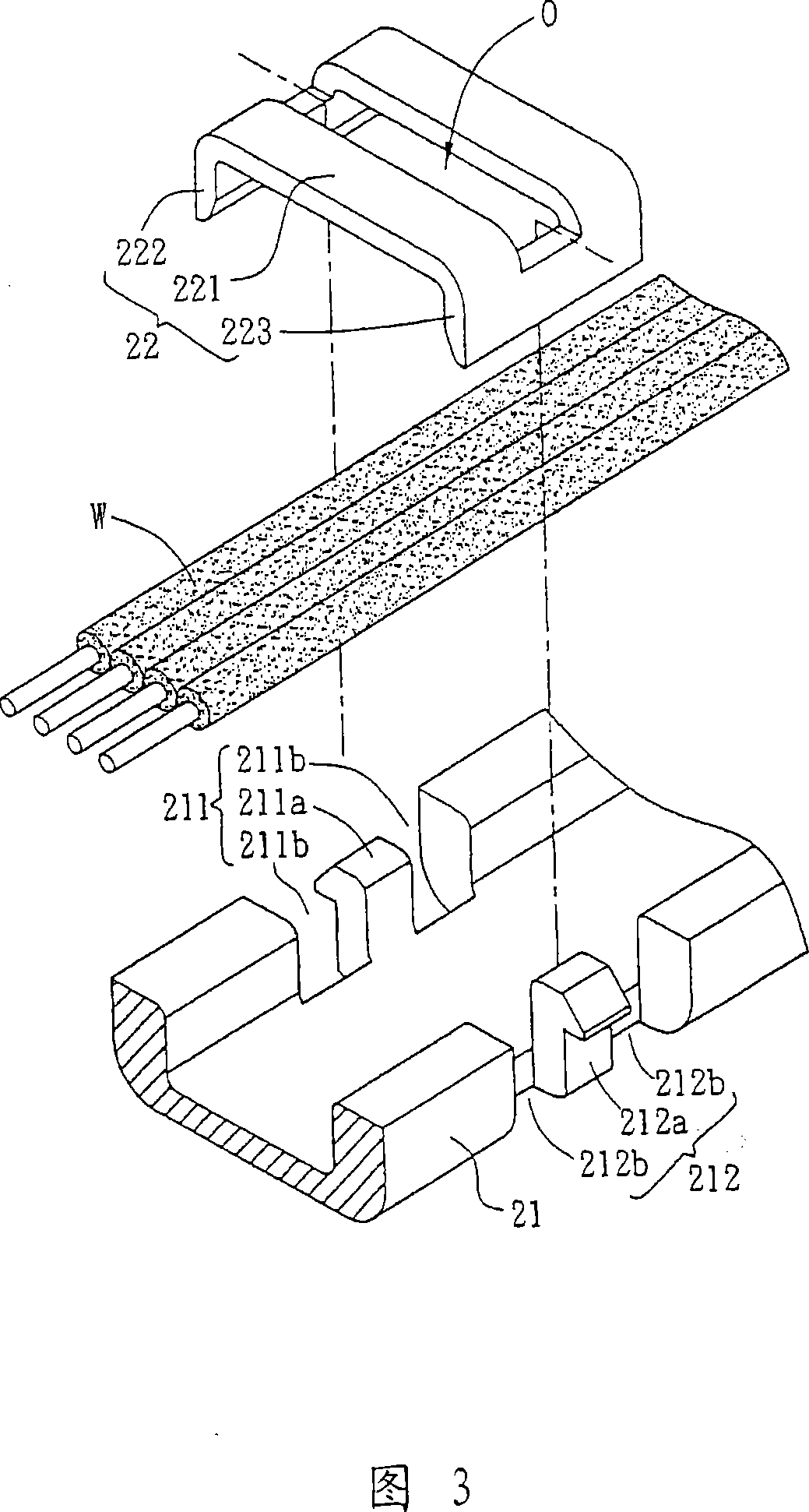

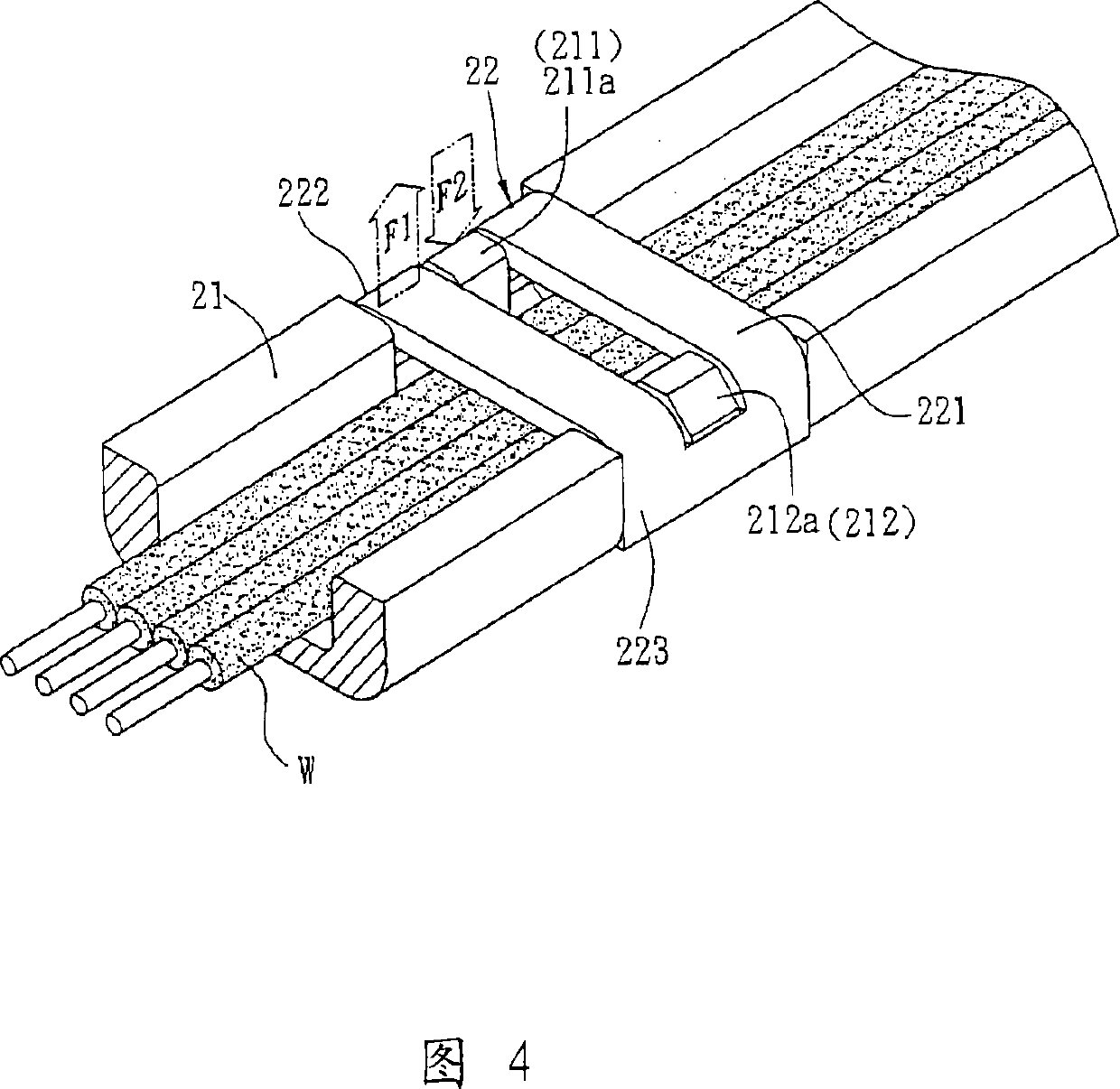

[0025] The fan frame of the preferred embodiment of the present invention will be described below with reference to related drawings, wherein the same components are denoted by the same reference numerals.

[0026] Please refer to Fig. 2, Fig. 3 and Fig. 4 at the same time, wherein Fig. 3 is an exploded and enlarged view of the wire groove and wire fixing element in Fig. 2, and Fig. 4 is a combination diagram of the wire groove and wire fixing element in Fig. 3 . The fan frame 2 of the preferred embodiment of the present invention includes at least one wire slot 21 and at least one wire fixing element 22 . The wire W is accommodated in the wire groove 21 and tightly fixed by the wire fixing element 22 . The fan frame 2 is, for example, an axial-flow fan frame or a centrifugal fan frame. This embodiment takes an axial-flow fan frame as an example for illustration.

[0027] At least two fixing portions 211 , 212 are correspondingly provided on the outer edge of the trunking 21 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com