Stopping caliper

A caliper and parking technology, applied in the direction of brake actuators, axial brakes, brake types, etc., can solve the problems of unstable braking torque, tight installation space and occupation of parking devices, and achieve stable braking torque , simple structure and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

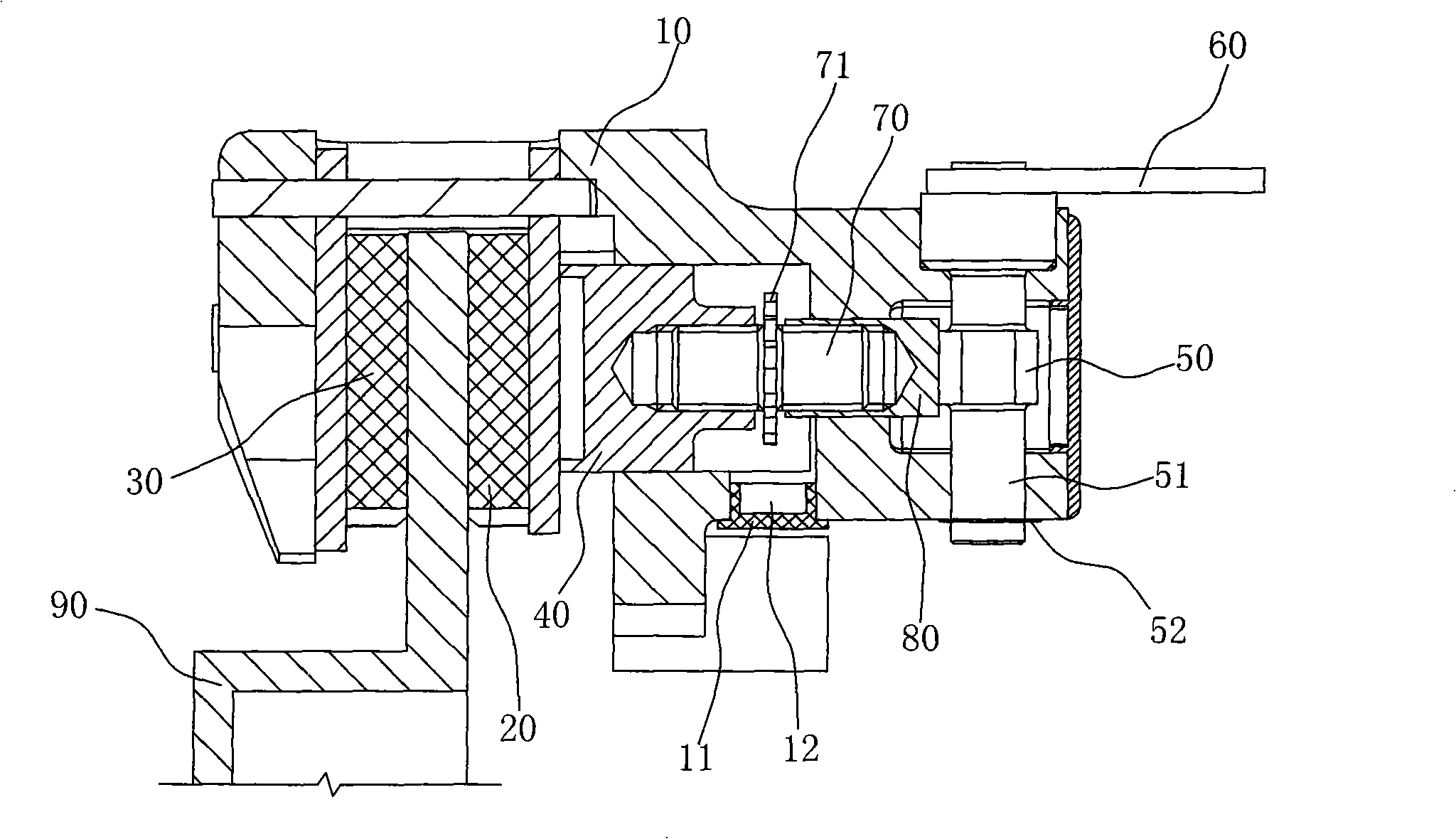

Image

Examples

Embodiment approach

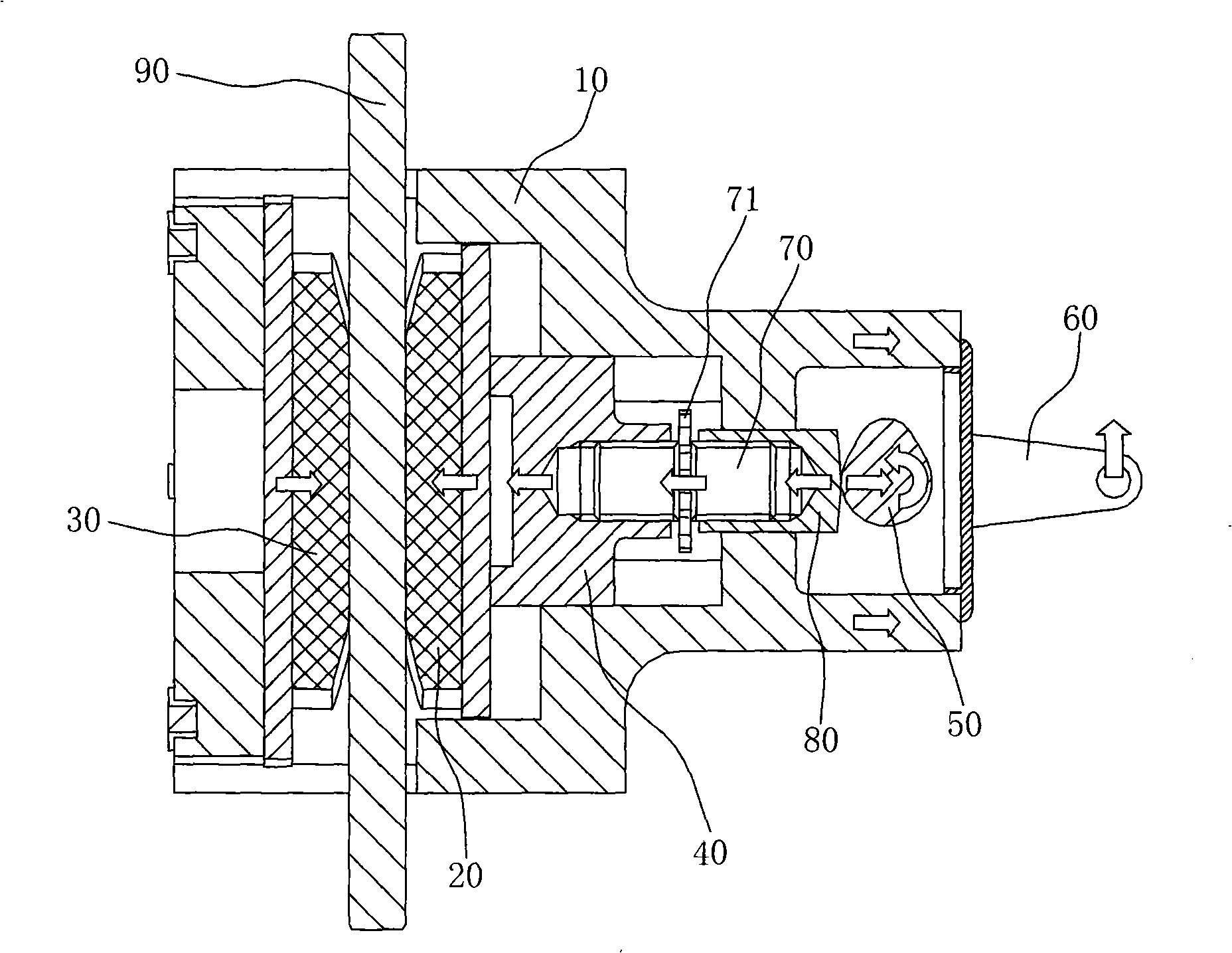

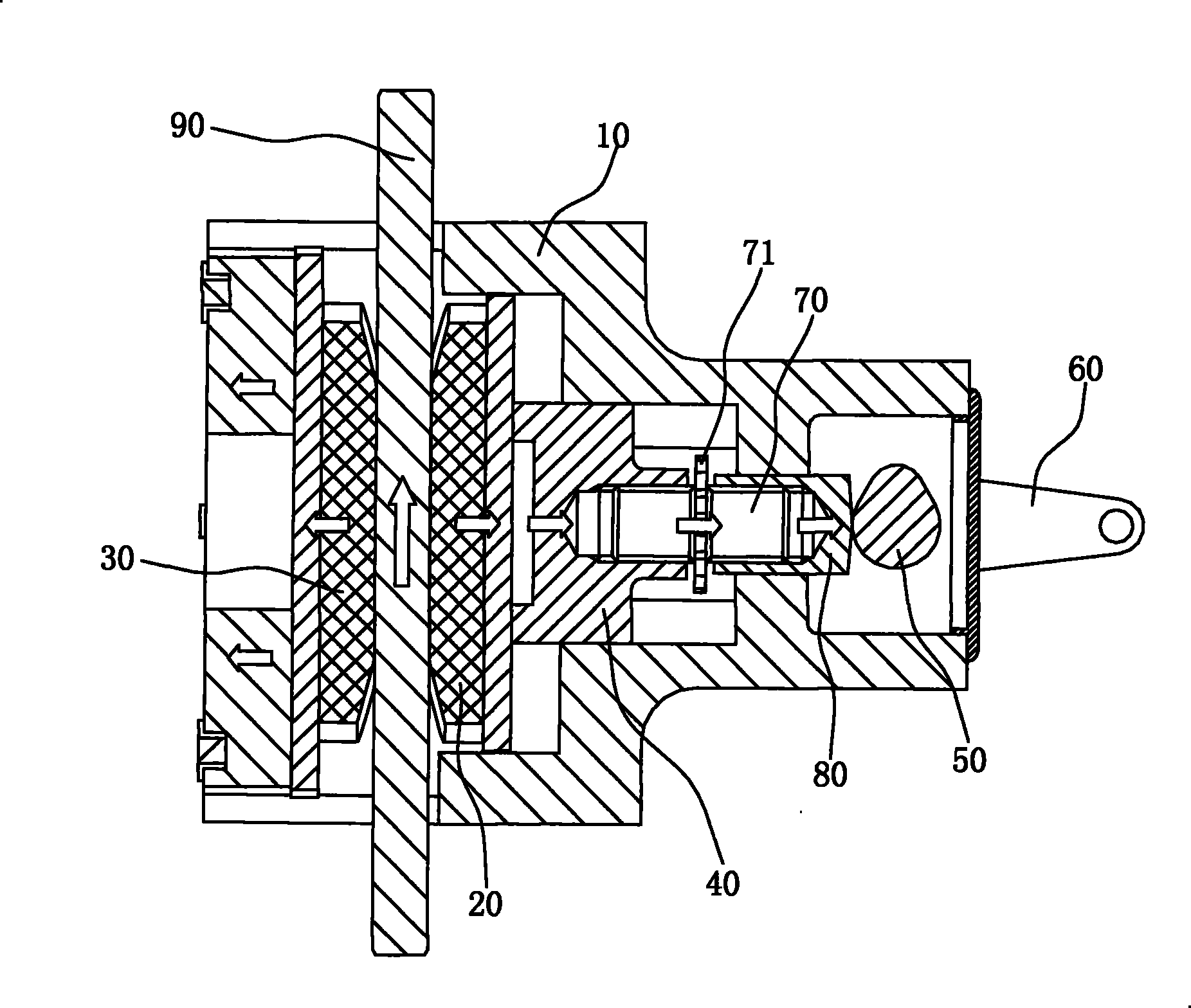

[0023] 1) Parking process

[0024] After the vehicle stops, the driver pulls the parking handle, and the power is transmitted to the parking pull arm 60 through a transmission mechanism such as a parking cable, such as figure 2 As shown by the arrow in the figure, the parking pull arm 60 will drive the camshaft 51 to rotate, and the camshaft 51 will drive the cam 50 to rotate accordingly. When the cam 50 rotates, it will drive the sheath 80 to move to the side of the piston 40, and the sheath 80 will then push The adjusting stud 70 moves to the side of the piston 40, and the adjusting stud 70 pushes the piston 40 to move to the side of the brake disc 90, and the piston 40 moves along the direction defined by the cavity in the caliper body 10, and pushes the movable brake block 20 Attached to the inner working surface of the brake disc 90; at the same time, when the cam 50 drives the sheath 80, the sheath 80 gives a reaction force to the cam 50, and this reaction force will ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com