Running fix test mechanism

A testing mechanism and mobile positioning technology, applied in the direction of measuring devices, mechanical devices, mechanical measuring devices, etc., can solve the problems of large gantry span, limited equipment positioning, and difficult motor drive, etc., to achieve reduced structural strength requirements and stable operation , cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

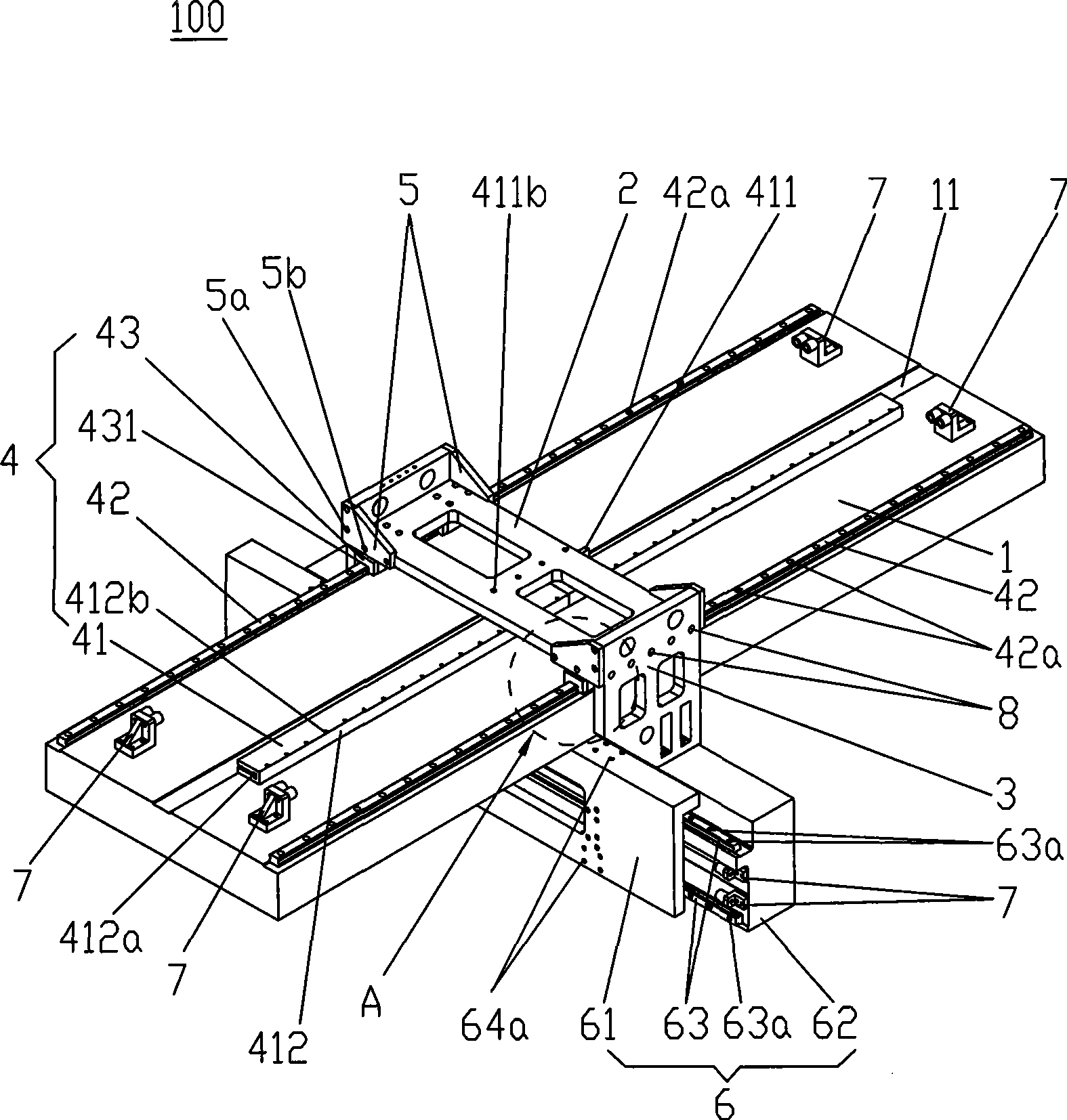

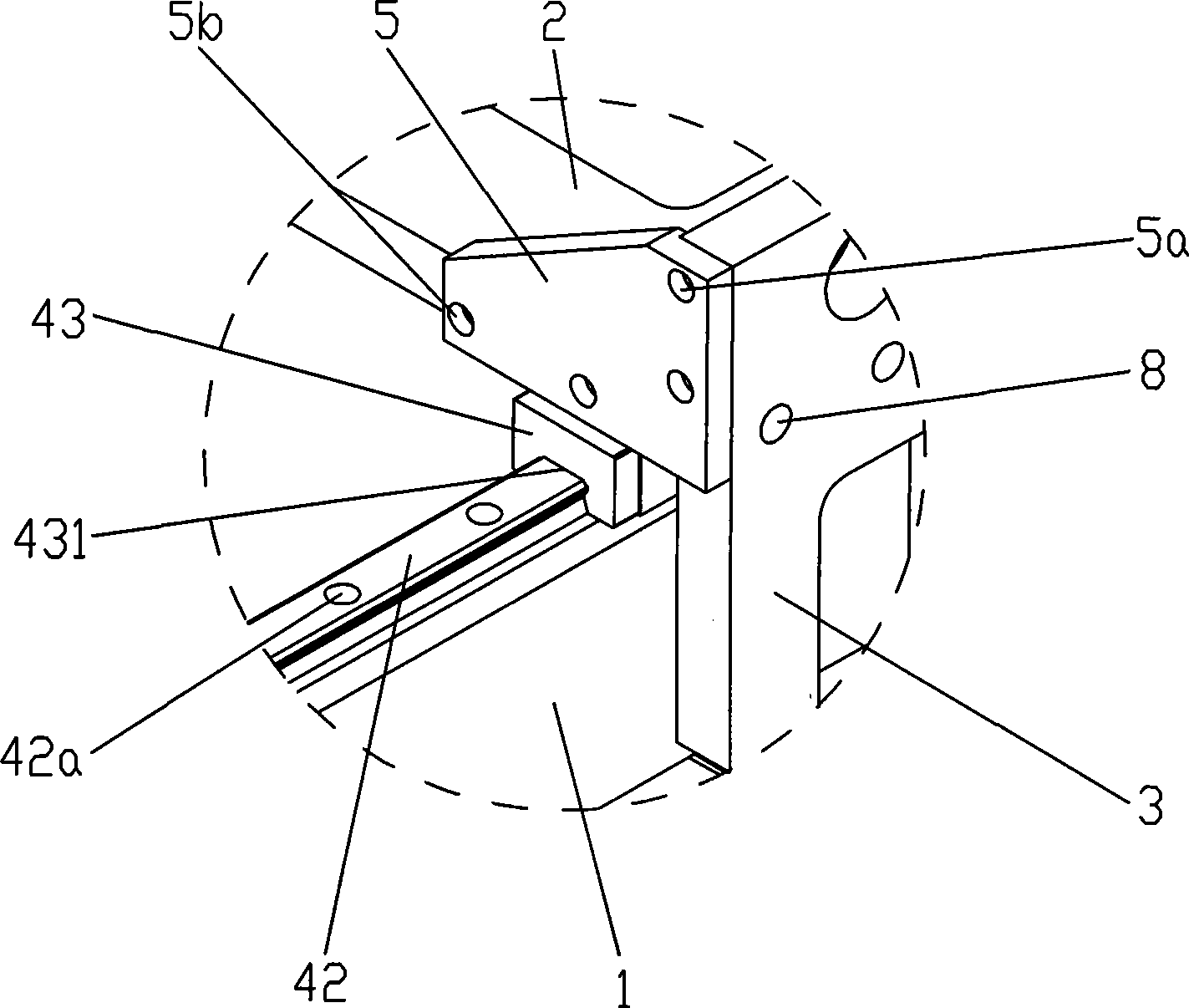

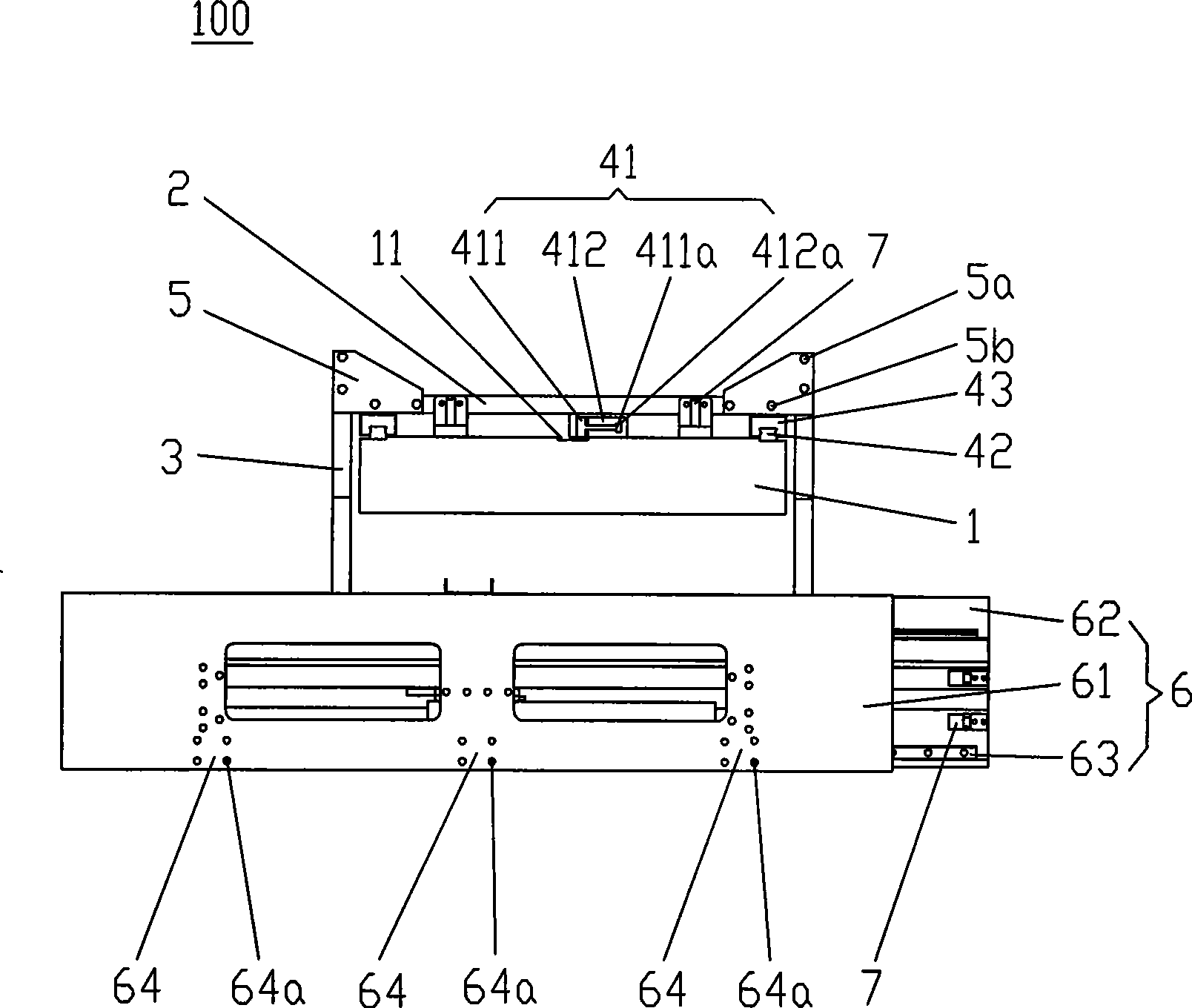

[0021] Such as figure 1 , figure 2 As shown, the mobile positioning testing mechanism 100 of the present invention includes a base plate 1, a crossbeam 2, and a boom frame 3. The base plate 1 is fixed on the workbench, the crossbeam 2 spans the base plate 1, and the boom The frame 3 is connected to both ends of the crossbeam 2 across the base plate 1 through screws 8. The mobile positioning test mechanism 100 of the present invention also includes a driving device 4, and the driving device 4 includes a linear motor 41, a first slide rail 42, And the first chute block 43 that has chute 431, described first slide rail 42 is installed on the longitudinal (long side direction of substrate) both sides of described substrate 1 by screw 42a, described first chute block 43 Fixedly installed on the beam 2 and the chute 431 is stuck on the first slide rail 42, one end of the linear motor 41 is fixed on the substrate 1 by a screw 42a along the longitudinal direction of the substrate 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com