Dynamic performance integrated test experimental device for high speed principal axis

A technology of dynamic performance and comprehensive testing, which is applied in the direction of mechanical bearing testing, etc., can solve the problems of insufficient automation and low integration, and achieve the effect of improving integration, overcoming low structural precision, improving automation and flexibility of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

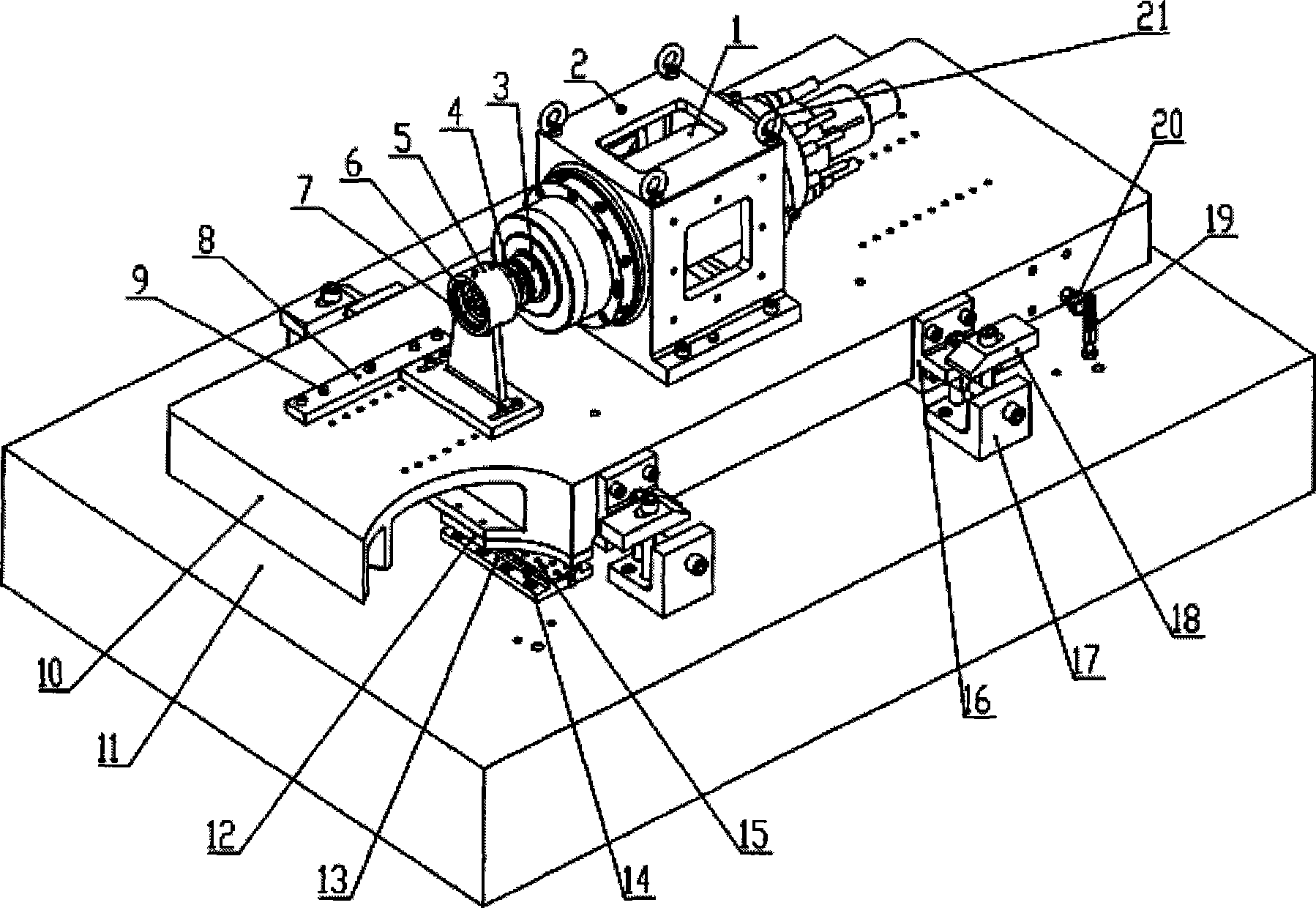

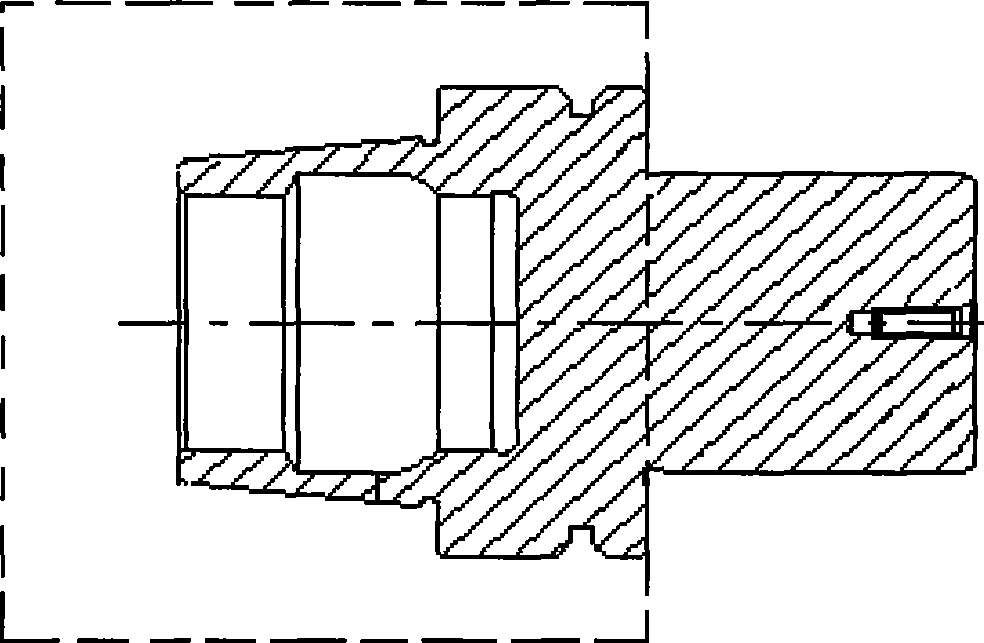

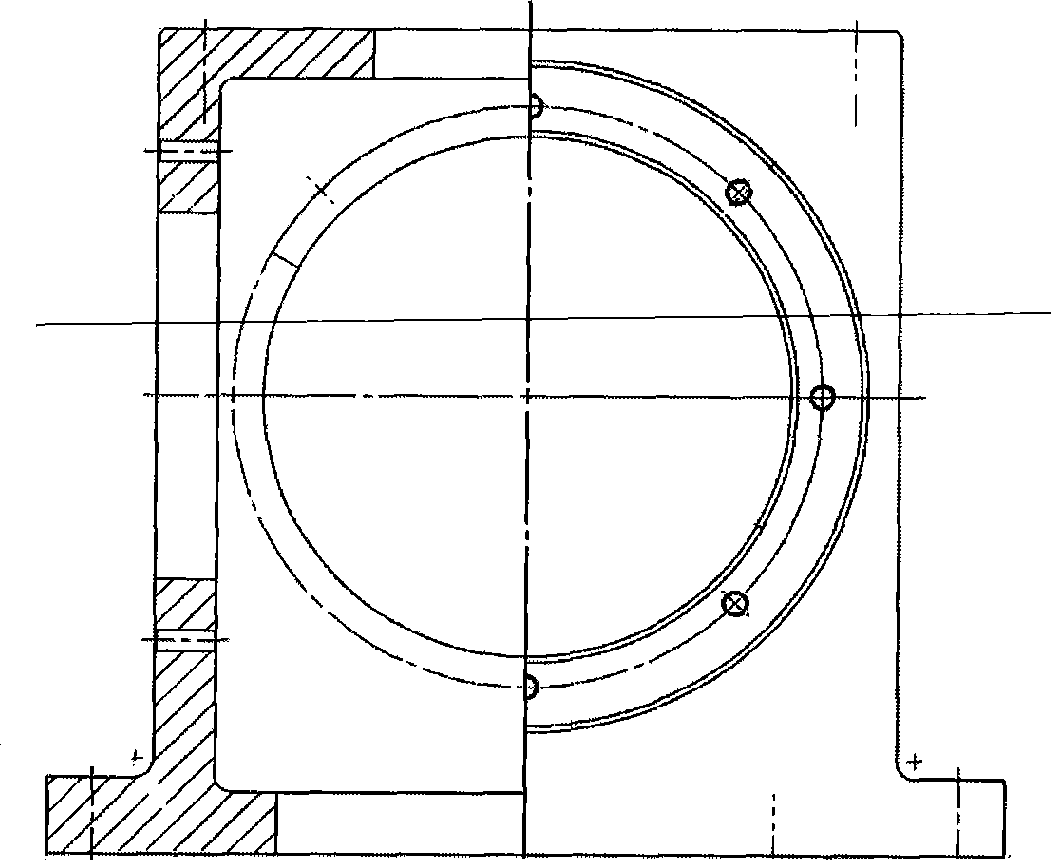

[0023] refer to figure 1 As shown, the test bench is mainly used to install and support the test object and the test sensor, and ensure that their relative positions meet the requirements of the test. The fixing and installation of the test object is realized by the main shaft positioning seat 2, and the installation of the displacement sensor 6 for testing the rotation error is realized by the sensor support 5, wherein the installation and positioning of the displacement sensor 6 is realized by the index plate 4 on the sensor support. accomplish.

[0024] The spindle test bench can be divided into the following four parts:

[0025] 1) Limiting and suspension parts: including support block 16, side positioning block 17, pressure plate 18, ring screw 21 and mounting screws, etc., to realize the fixing of the main shaft part when the side vibr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com