Production of layout and photo mask and graphic method

A technology of layout method and manufacturing method, which is applied to the original parts, optics, and opto-mechanical equipment for opto-mechanical processing, can solve the problems of inconsistent critical dimensions of circuit patterns, affecting the imaging quality of semiconductor devices, etc., and achieve the effect of improving imaging quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

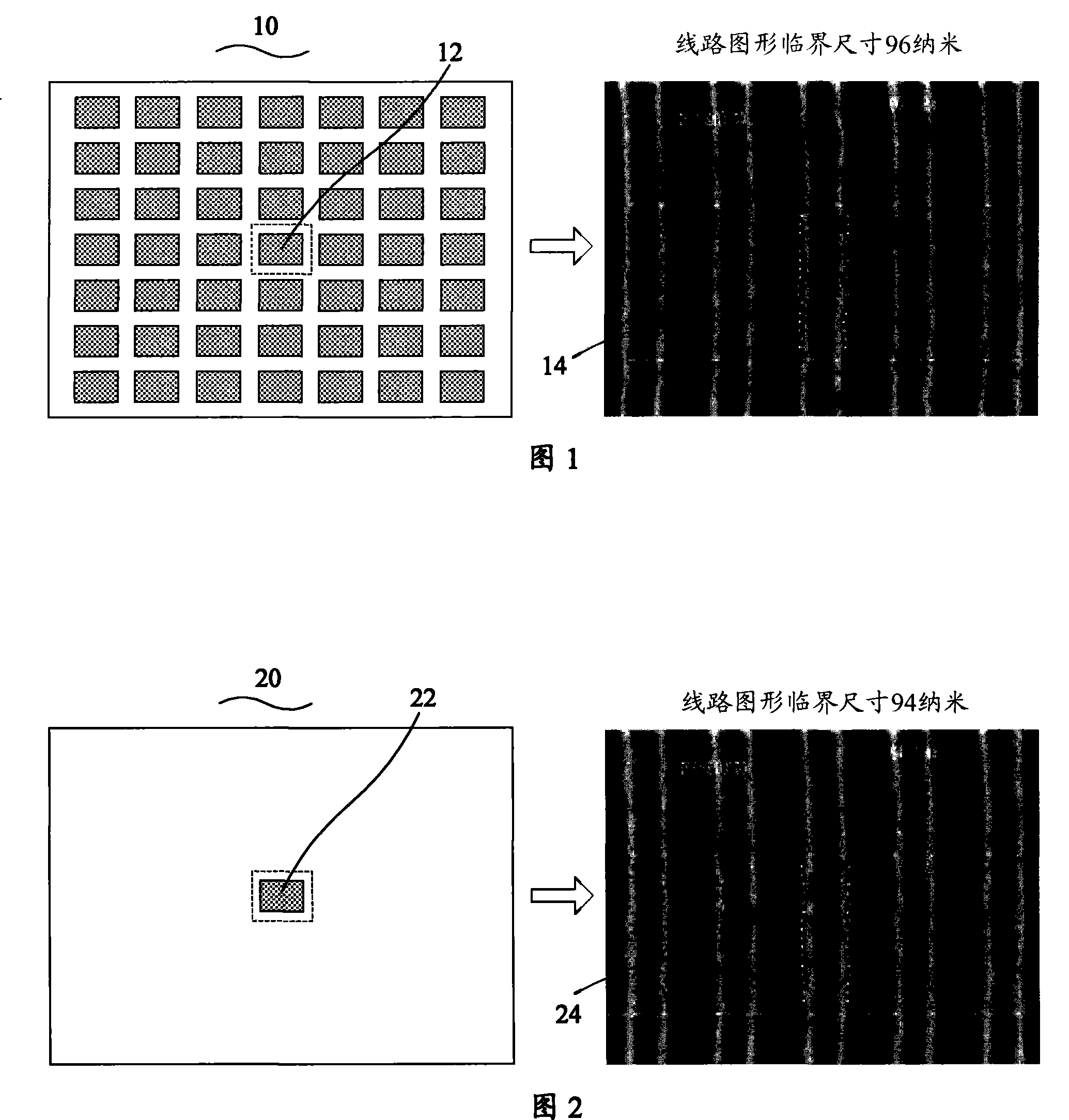

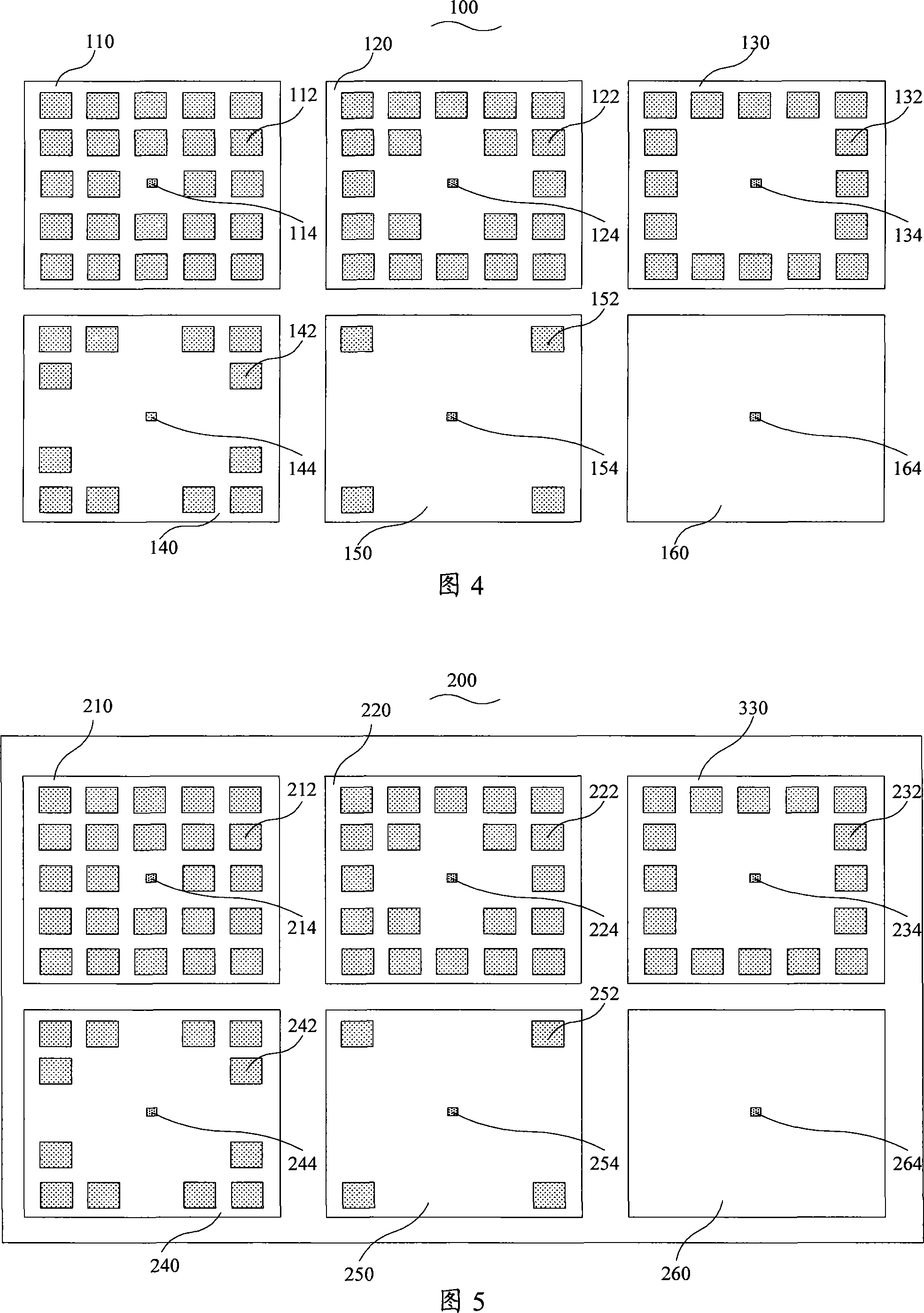

[0028] According to the density of semiconductor devices on the wafer, it can be divided into device dense area, device semi-dense area and device isolated area. The distance between the circuit patterns in the device dense area is equal to 1CD, and the distance between the circuit patterns in the device semi-dense area is greater than 1CD and less than Equal to 3CD, the distance between the circuit patterns in the isolated area of the device is greater than 3CD.

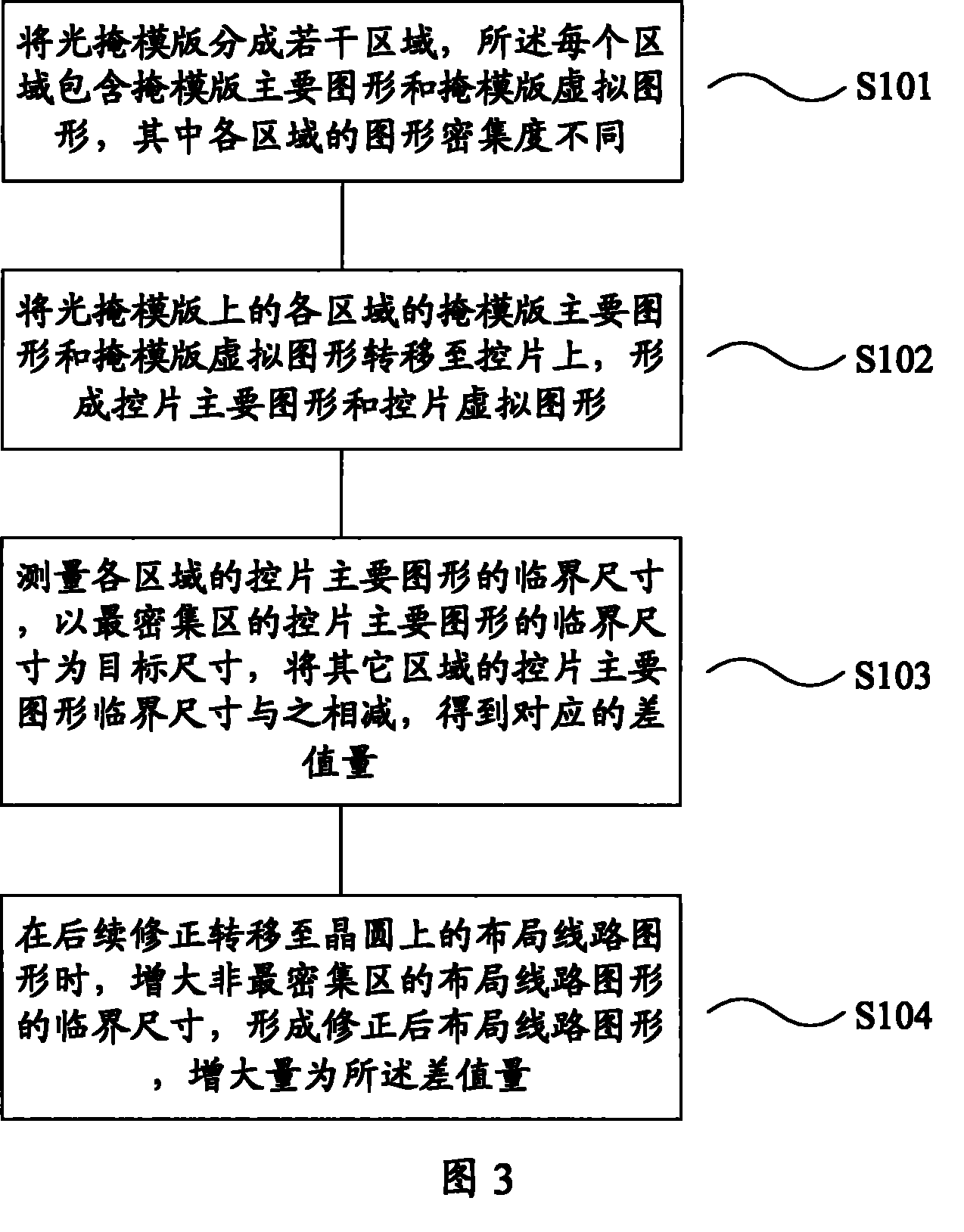

[0029] The invention divides the photomask plate into several regions with different pattern density; transfers the patterns of each region on the photomask plate to the photoresist film of the control sheet; measures the critical dimension of the photoresist main pattern in each region to obtain The critical size of the main graphics in the densest area is the target size, and the critical size of the main graphics in other areas is subtracted from it to obtain the difference; increase the critical size of the lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| critical dimension | aaaaa | aaaaa |

| critical dimension | aaaaa | aaaaa |

| critical dimension | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com