Wafer on-line detection method and on-line detection device

A detection device and detection method technology, applied in the direction of semiconductor/solid-state device testing/measurement, etc., can solve the problem of poor analysis accuracy of detection results, and achieve the effects of improving analysis accuracy, accurate judgment, and improved accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0051] The first embodiment of the present invention introduces a new method for on-line detection of wafers. The selection of detection points is different from that of traditional methods, which can effectively improve the relationship between the fitting curve of each detection point data and the actual detection data of the entire wafer. The degree of coincidence between the fitted curves.

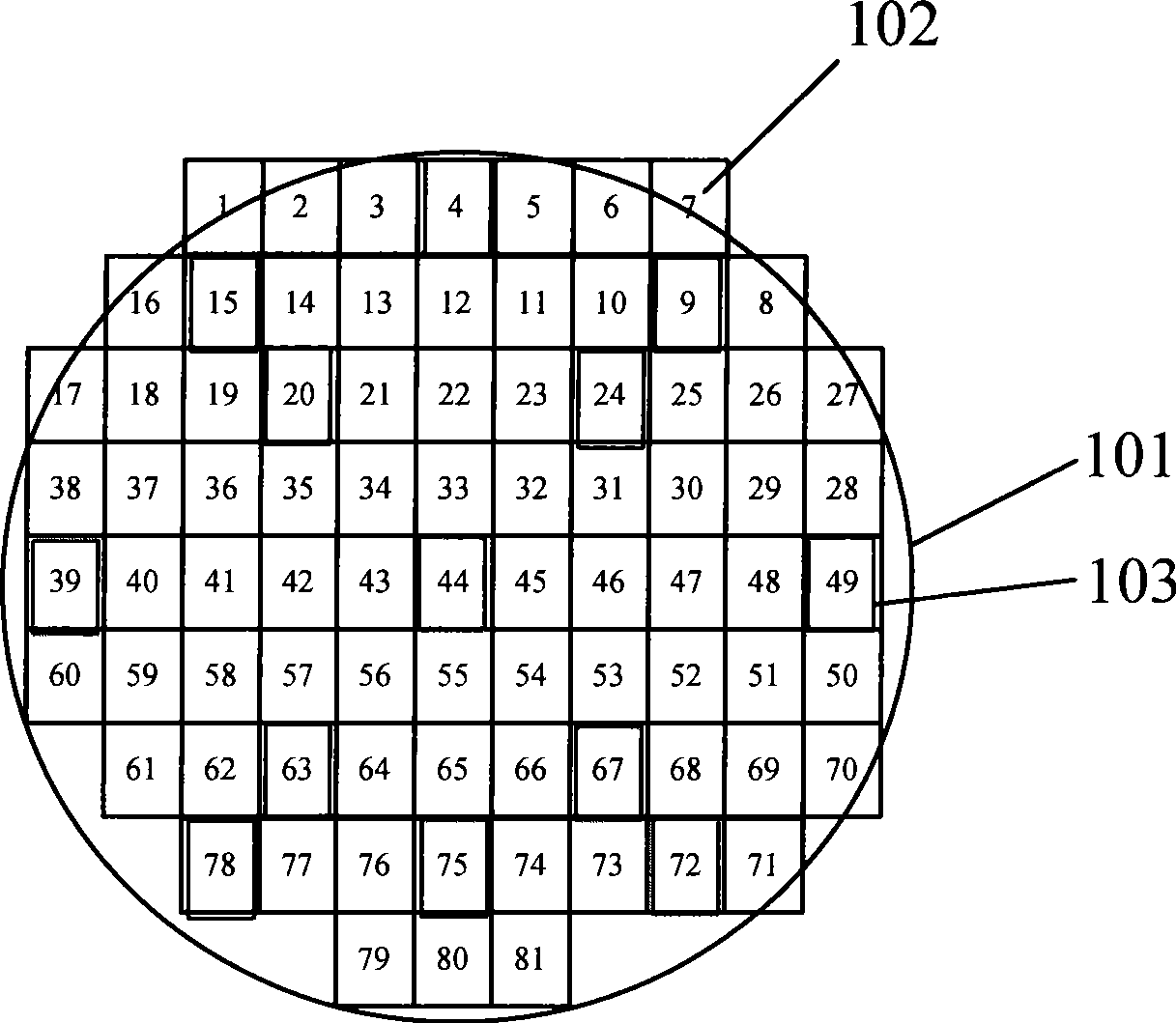

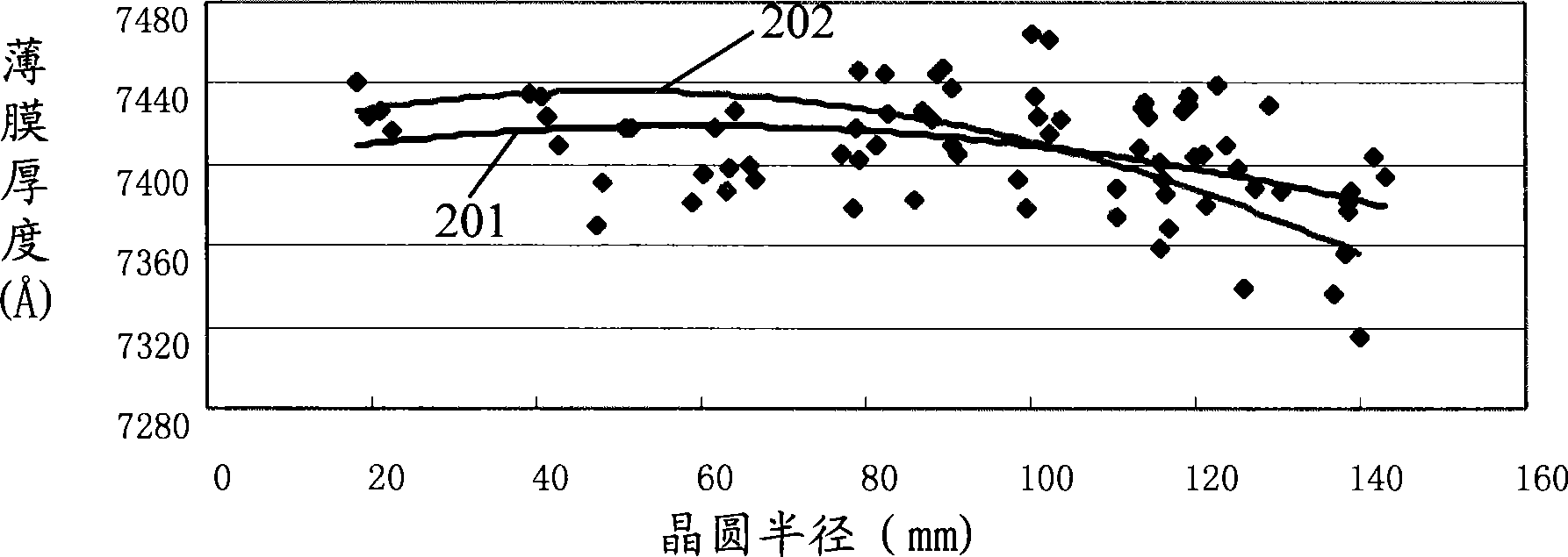

[0052] In the traditional wafer detection method, the selection of each detection point is determined according to the position distribution of each periodically arranged unit on the wafer, such as figure 1 As shown, 9 to 13 units are usually selected symmetrically with the center of the wafer as the center, and the distribution of the detection results is obtained by testing the detection area of each selected unit, and the actual distribution of the entire wafer is deduced from the obtained distribution. Process condition. However, practice shows that the data distribution of dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com