Cutting tool and cutting insert

A technology of cutting inserts and cutting tools, applied in the direction of milling cutting inserts, manufacturing tools, milling cutters, etc., can solve the problems of surface finishing of cutting materials W, large connection angle, and increased cutting resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

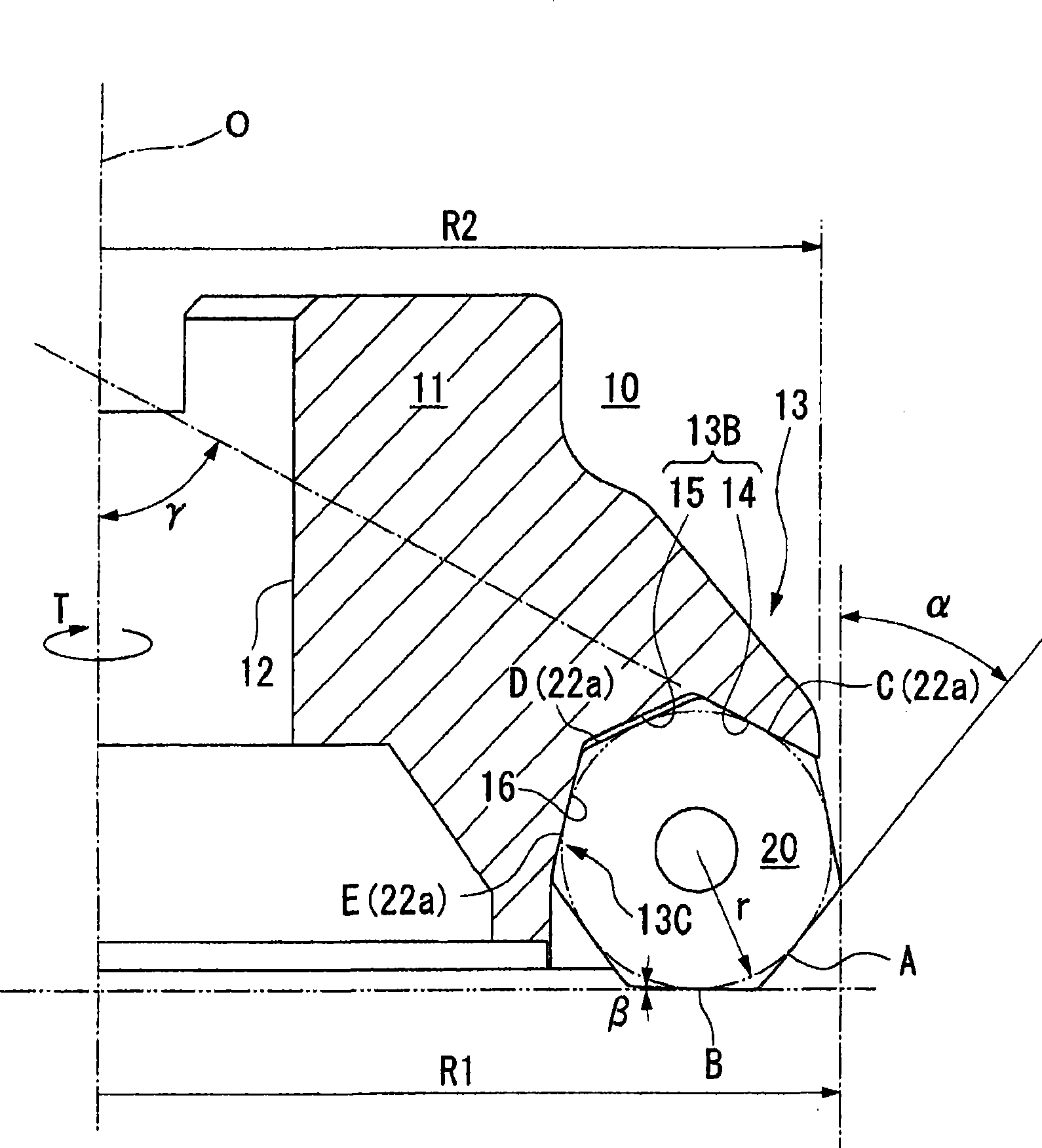

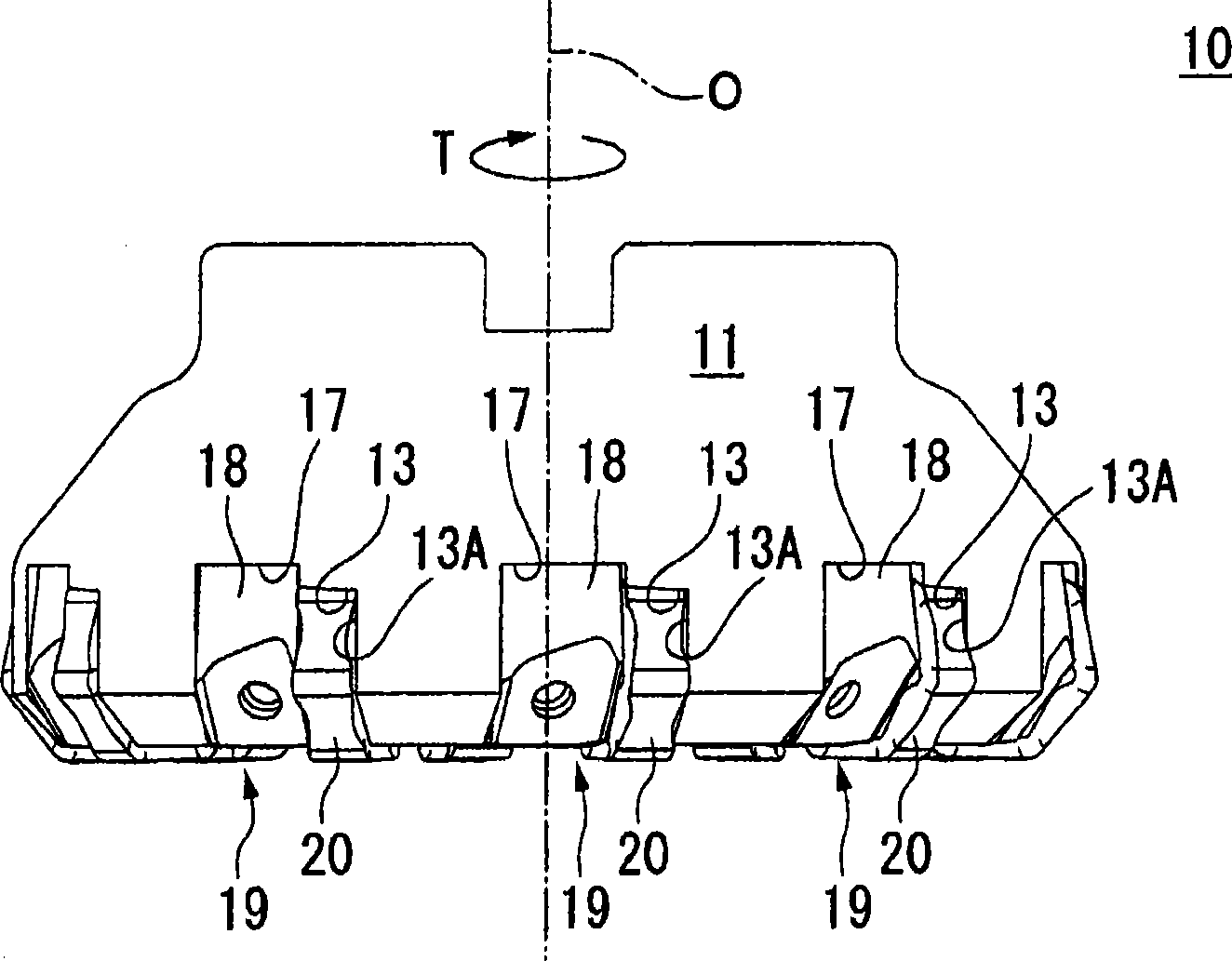

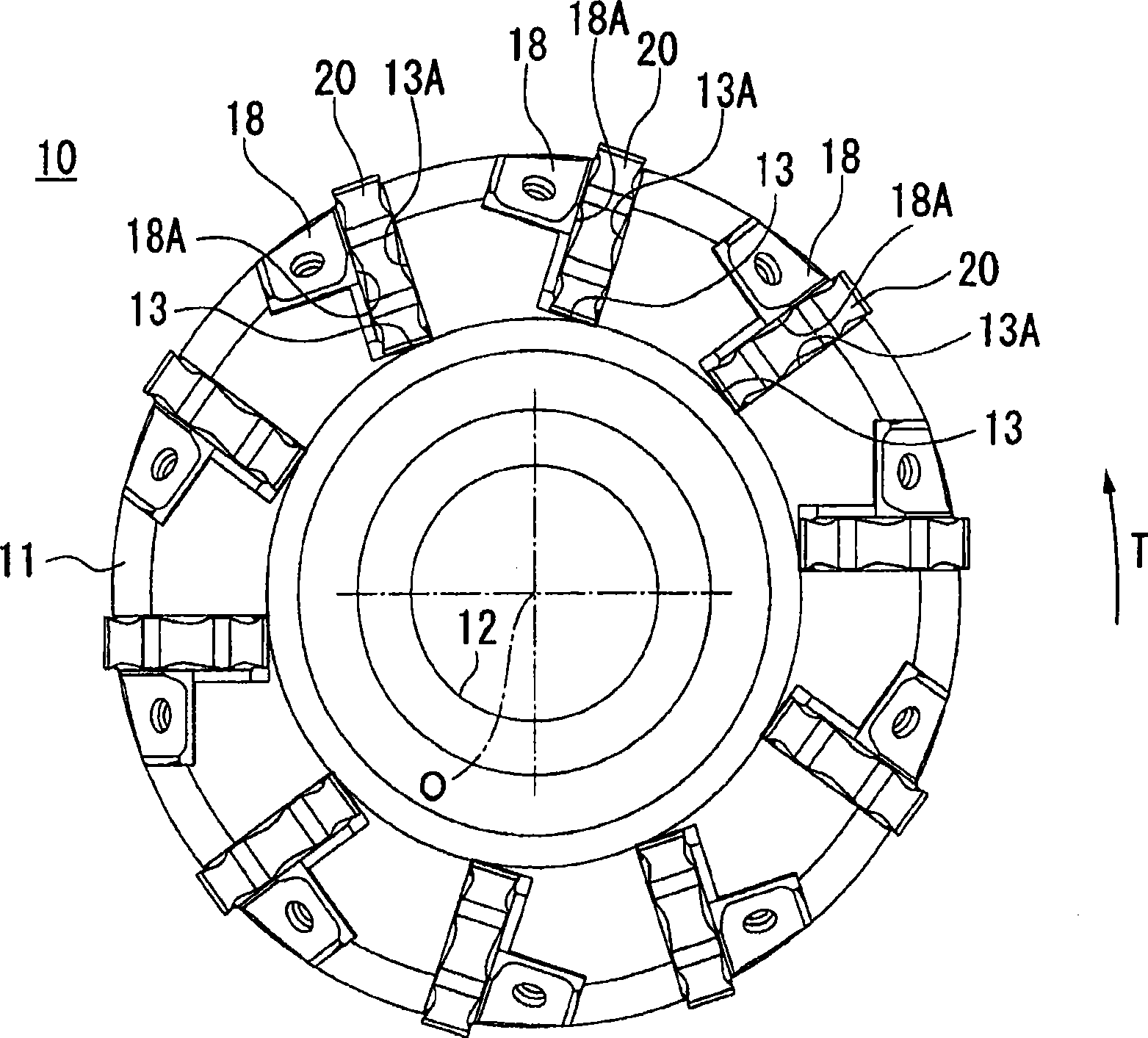

[0057] Embodiments of the present invention will be described with reference to the drawings. Figure 1 to Figure 3 A milling cutter as a cutting tool according to the present embodiment is shown. In addition, Figure 4 to Figure 7 Indicates the cutting insert mounted on this milling cutter. In addition, the milling cutter of this embodiment looks rightward toward the surface to be processed ( figure 1 The so-called right-hand knife that rotates in the T direction) and is equipped with the cutting blade of the right-hand knife.

[0058] The milling cutter 10 is used when performing plane machining on cast iron or steel and other cut materials, such as figure 2 and image 3 As shown, the milling cutter 10 has a substantially disc-shaped tool body 11 centered on the axis 0 . A mounting hole 12 extending along the axis 0 is bored in the tool body 11 .

[0059] On the outer periphery of the front end of the tool main body 11, a mounting seat 13 for mounting a cutting inser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com