Onboard electronic device and vehicle mounting the same

A technology for electronic devices and vehicles, applied in vehicle components, support structure installation, protection against damage caused by electrostatic discharge, etc., can solve the problem of wasting time and energy, and achieve the effect of improving anti-static ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

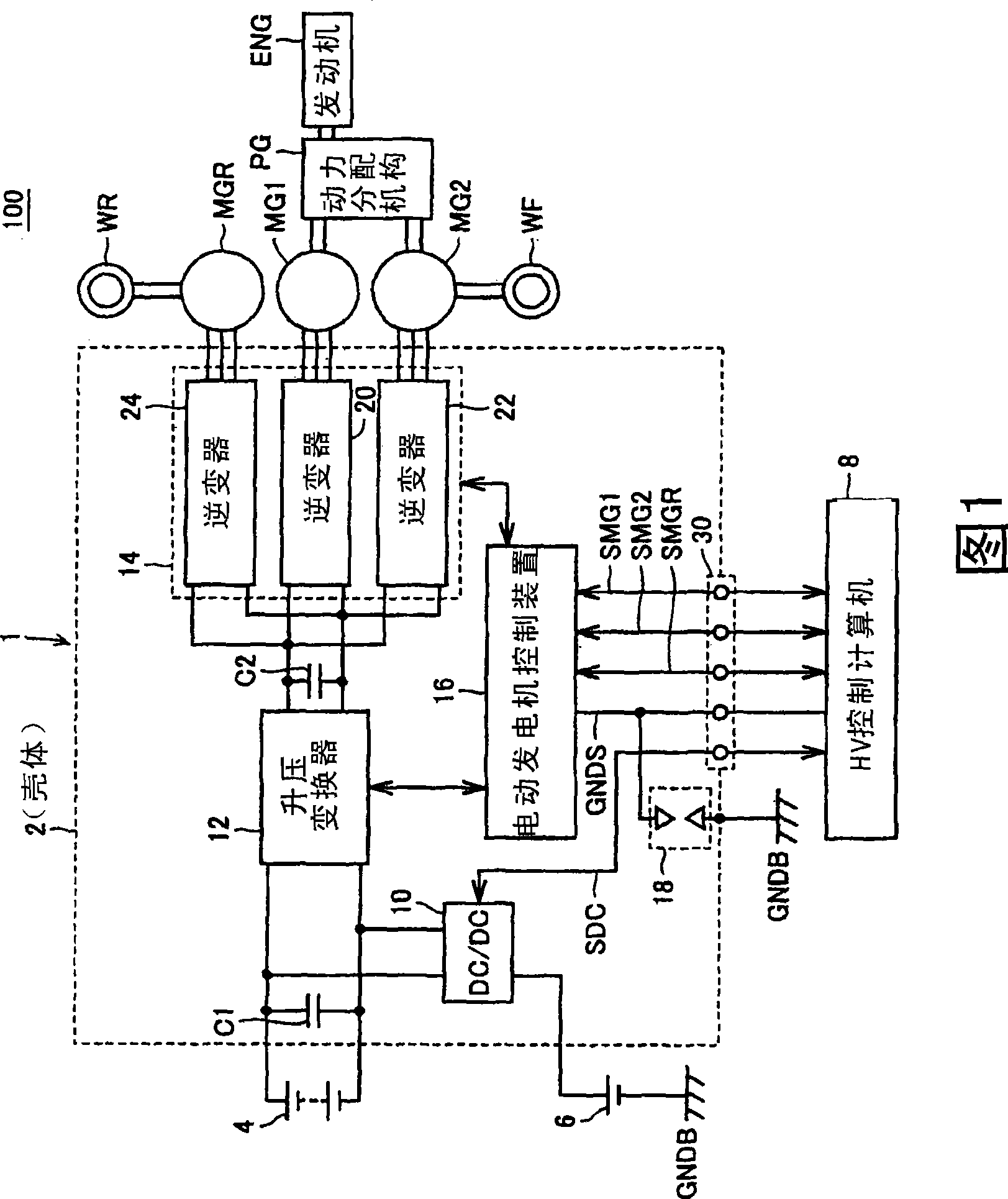

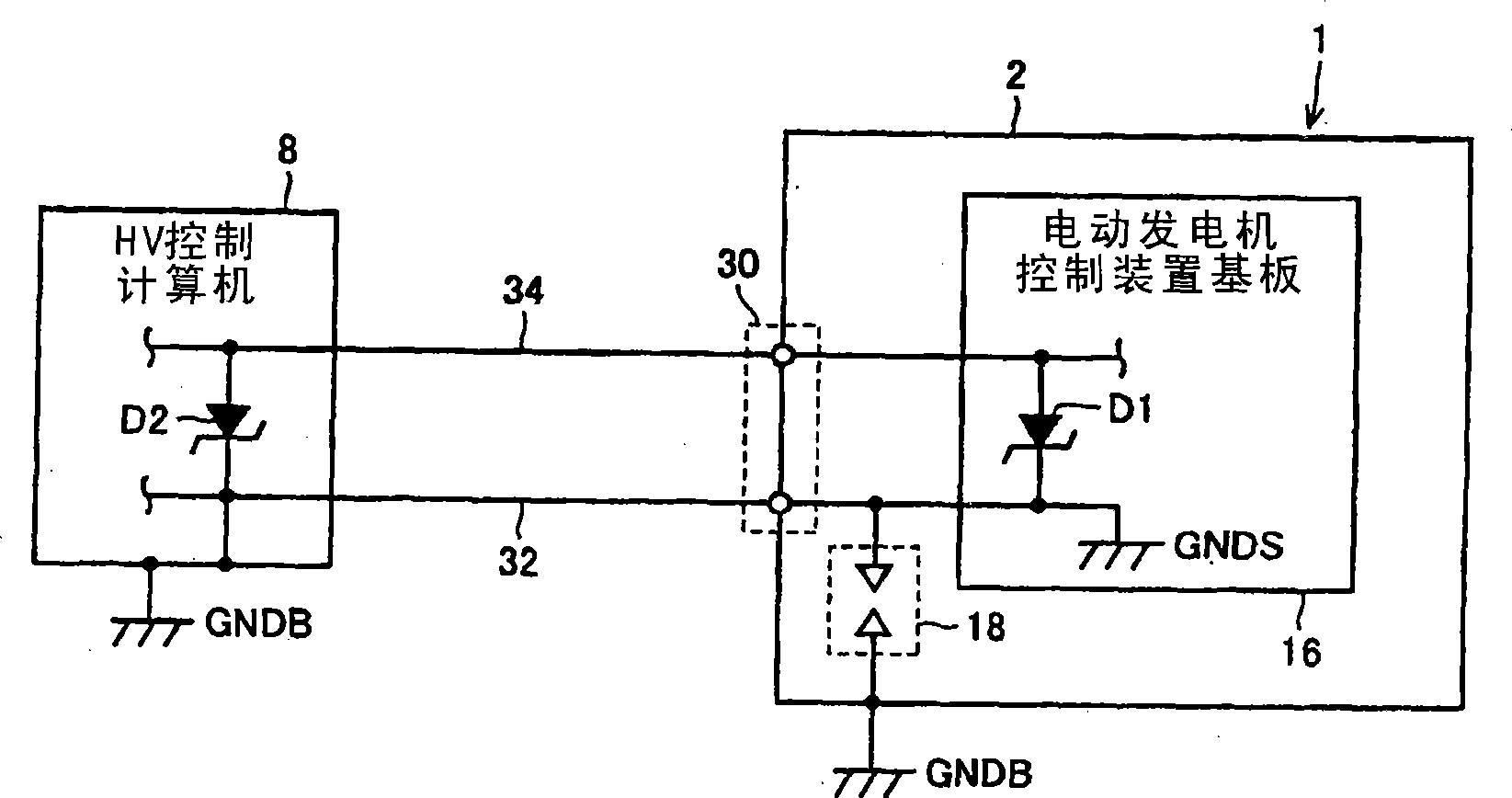

[0057] FIG. 1 is a block diagram showing the configuration of a vehicle 100 according to the embodiment of the present invention.

[0058] Referring to FIG. 1 , a vehicle 100 is a hybrid vehicle including: a high-voltage battery 4, an auxiliary battery 6, an inverter unit 1, an HV (hybrid) control computer 8, motor generators MG1, MG2, and MGR, and a power distribution mechanism PG. , engine ENG, front wheel WF, rear wheel WR.

[0059] Power split mechanism PG is connected to engine ENG and motor generators MG1, MG2 to distribute power between them. For example, the power distribution mechanism may use a planetary gear mechanism having three rotation shafts of a sun gear, a carrier, and a ring gear. These three rotation shafts are connected to the rotation shafts of engine ENG, motor generators MG1, MG2, respectively. A speed reducer related to the rotation shaft of motor generator MG2 may also be mounted inside power split mechanism PG.

[0060] The rotating shaft of motor...

Embodiment approach 2

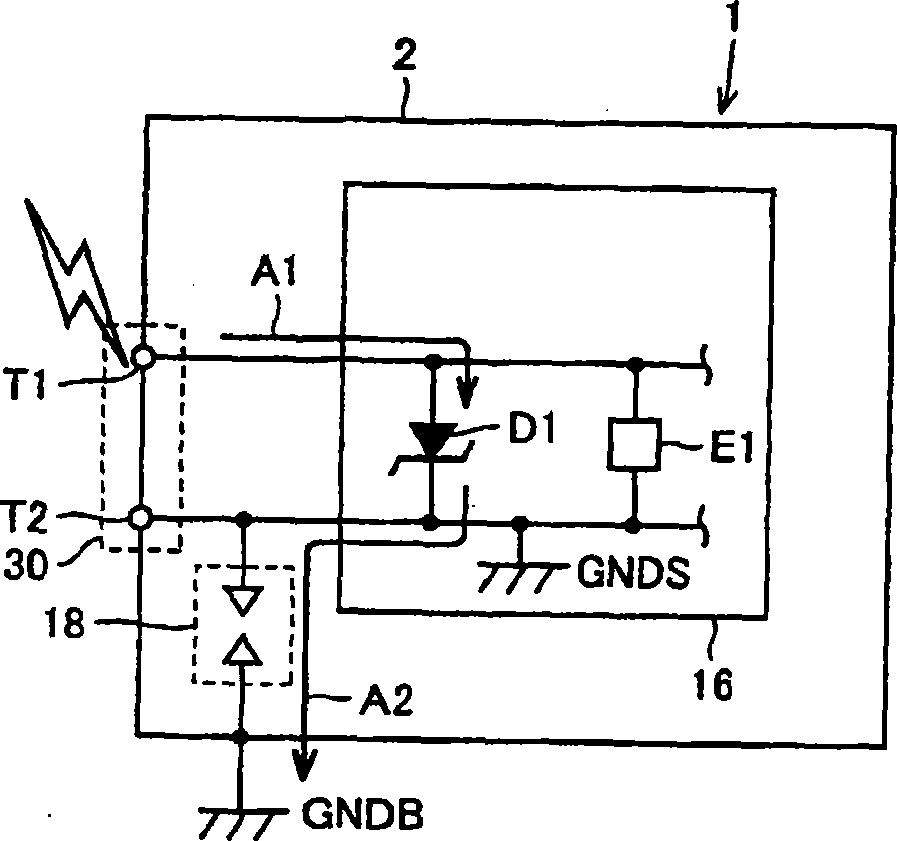

[0116] In Embodiment 1, the discharge gap was formed between the conductive plate and the case, but the discharge gap may be formed in another part.

[0117] Figure 11 It is a figure for demonstrating the discharge gap of the inverter unit of Embodiment 2.

[0118] Figure 12 is showing Figure 11 The cross-sectional view of the XII-XII section.

[0119] refer to Figure 11 , Figure 12 , the inverter unit 1A also includes: a conductive body ground pattern 194, and an insulating member 155 and a screw 161 as a conductive member that electrically connects the body ground pattern 194 to the housing 102, and the conductive body ground pattern 194 Discharge gap 18A is formed on control substrate 117 between conductive pattern 192 . An external thread is formed at a lower portion of the spacer member 155 , and the external thread portion is screwed into a screw hole formed on the housing 102 . On the upper portion of the spacer member 155, a hole having an internal thread f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com