Method for treating plant disease induced by loess slope spalling

A technology for slopes and loess, applied in botanical equipment and methods, excavation, biocide, etc., can solve the problems of high cost and unsatisfactory peeling effect of thick layers, and achieve the effect of convenient operation, good treatment effect, and lush branches and leaves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

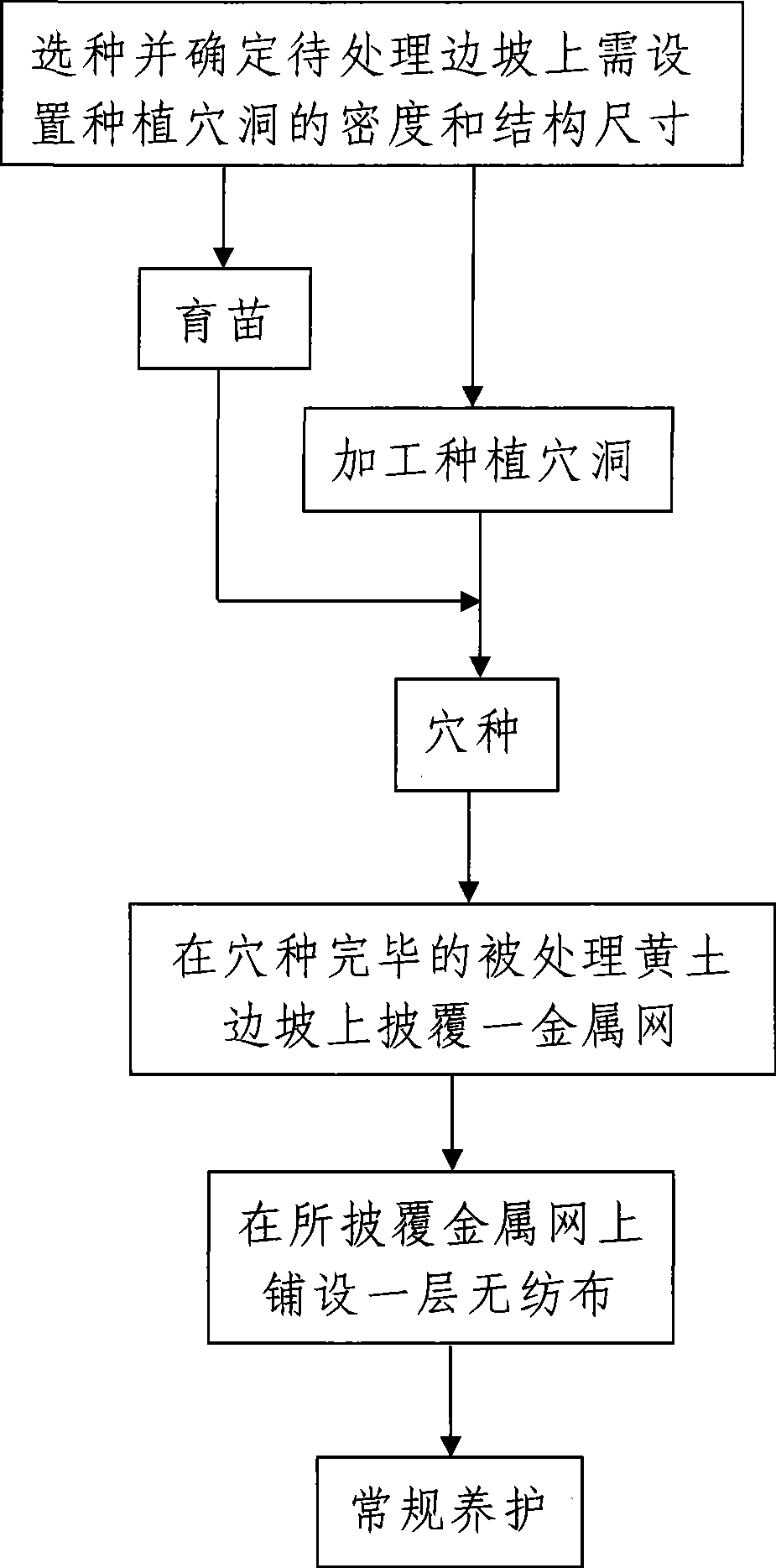

[0035] Such as figure 1 Shown, the method for treating loess slope spalling disease of the present invention, comprises the following steps:

[0036] Step 1. Select the grass species and determine the density and structural size of the planting holes on the loess slope to be treated according to the conventional hole method, and then determine the number of seedlings required. The selected grass species is suitable for the geographical environment of the construction road section. Grass species that grow and have well-developed root systems, and the loess slope to be treated is the loess slope that will have peeling of the surface crust or peeling of the middle layer as determined by geological survey. In addition, it should be noted that it is also necessary to check whether there are ditches at the top of the slope to be treated and whether the ditches are blocked to ensure that the ditches at the top of the slope are unobstructed to prevent direct erosion of the slope by ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com