Tire with component containing aramid fibers

A fiber, element technology used in the field of pneumatic tires to solve problems such as rubber dispersion and/or poor adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

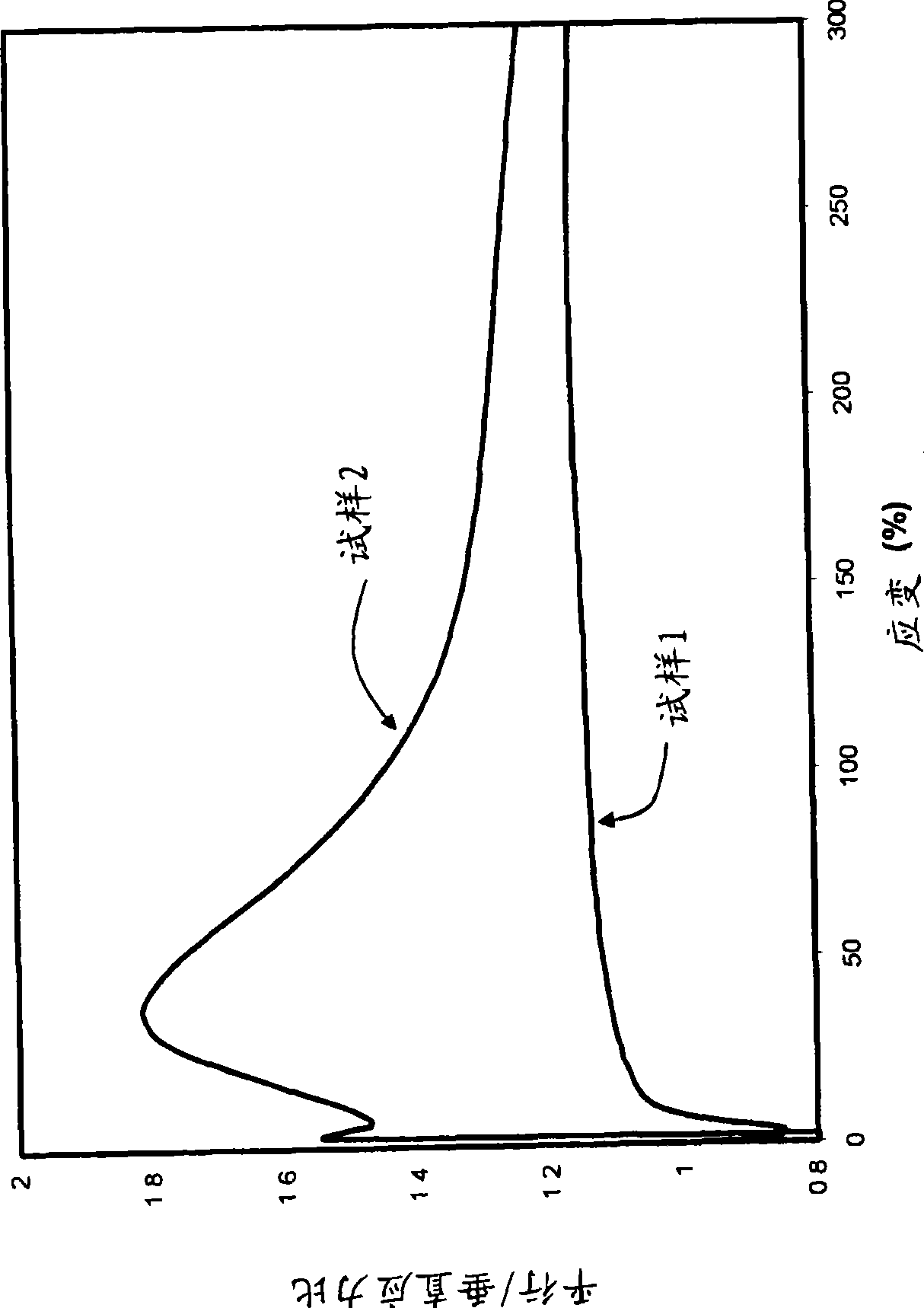

[0060] In this example, the effect of adding short fibers to a traveler rubber composition according to the present invention is illustrated. According to the formula shown in Table 1, the rubber composition containing diene-based elastomer, filler, processing aid, anti-degradation agent and curing agent was prepared, all amounts are in parts by weight (phr) per 100 parts by weight of base elastomer give. Sample 1 contained no short fibers and was used as a control. Sample 2 includes 3000 staple and representative of the invention.

[0061] Rubber specimens were rolled into sheets and cut into tensile specimens. The tensile specimens were cut in two orientation directions, one in the direction of test pull parallel to the direction of specimen rolling and one in the direction of test pull perpendicular to the direction of specimen rolling. In this way, the effect of fiber orientation (usually in the rolling direction) and thus the anisotropy of the rubber composition is ...

Embodiment 2

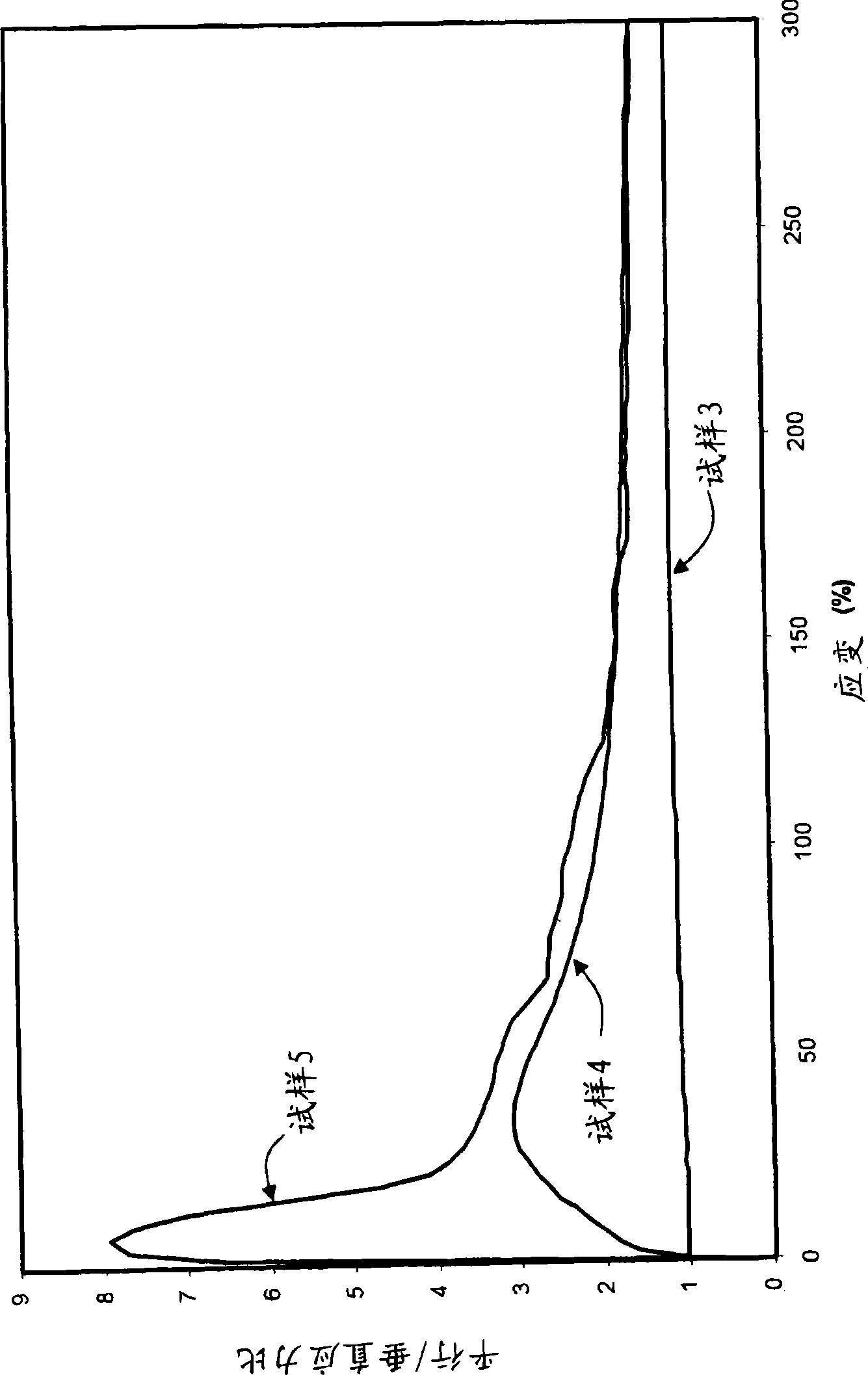

[0089]In this example, the effect of adding short fibers to a traveler rubber composition according to the present invention is illustrated. According to the formula shown in Table 1, the rubber composition containing diene-based elastomer, filler, processing aid, anti-degradation agent and curing agent was prepared, all amounts are in parts by weight (phr) per 100 parts by weight of base elastomer give. Sample 3 contained no short fibers and was used as a control. Sample 4 includes 3000 staple and representative of the invention. Sample 5 included short aramid fibers treated with nylon and was a comparative sample.

[0090] Rubber specimens were rolled into sheets and cut into tensile specimens. The tensile specimens were cut in two orientation directions, one in the direction of test pull parallel to the direction of specimen rolling and one in the direction of test pull perpendicular to the direction of specimen rolling. In this way, the effect of fiber orientation (...

Embodiment 3

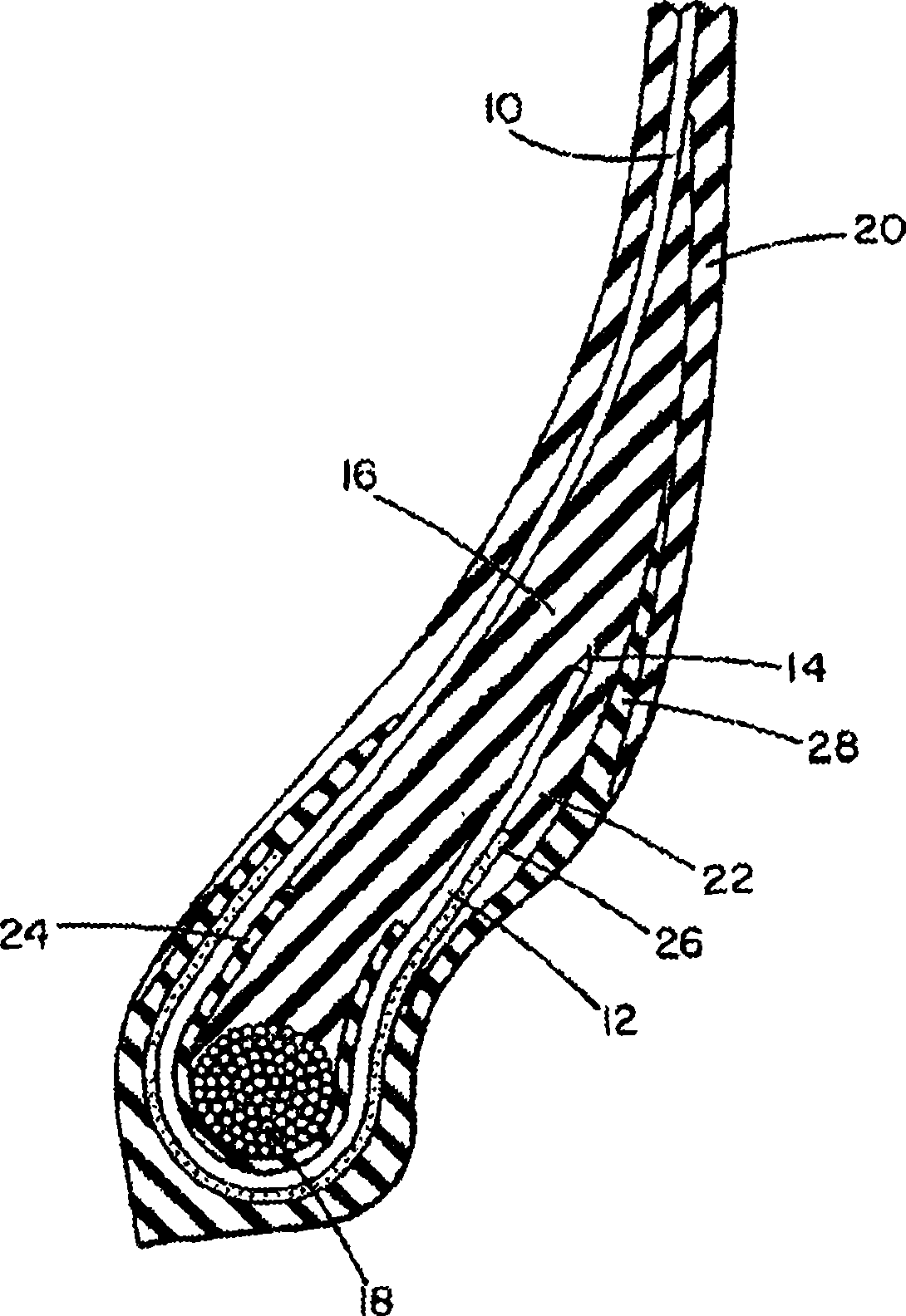

[0116] This example illustrates the effect of using a traveler comprising the rubber composition of the present invention. Three tires of the same mass were manufactured, each with a different wire wrap construction. The tire 1 was made with a flipper with conventional reinforcing cords. Tire 2 was made with a wire runner having a rubber compound with short oriented fibers of the present invention. The tire 3 is made with a flipper with a rubber compound without fibers or cords. The tangential stiffness of the tire is measured under rated tire load, measuring 20mm deflection under a load of 492kg. The results are shown in Table 3.

[0117] table 3

[0118] Tire No. Bead Cloth Reinforcement Vertical Stiffness (N / mm 2 )

[0119] 1 cord 278

[0120] 2 staple fiber 271

[0121] 3 none 264

[0122] As shown in Table 3, the tires made with the inventive traveler showed good vertical stiffness between the cord reinforced and unreinforced traveler.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com