Draft roller

A drafting roller and drafting device technology, which is applied in drafting equipment, textiles, papermaking, spinning machines, etc., can solve problems such as troubles and achieve cost-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

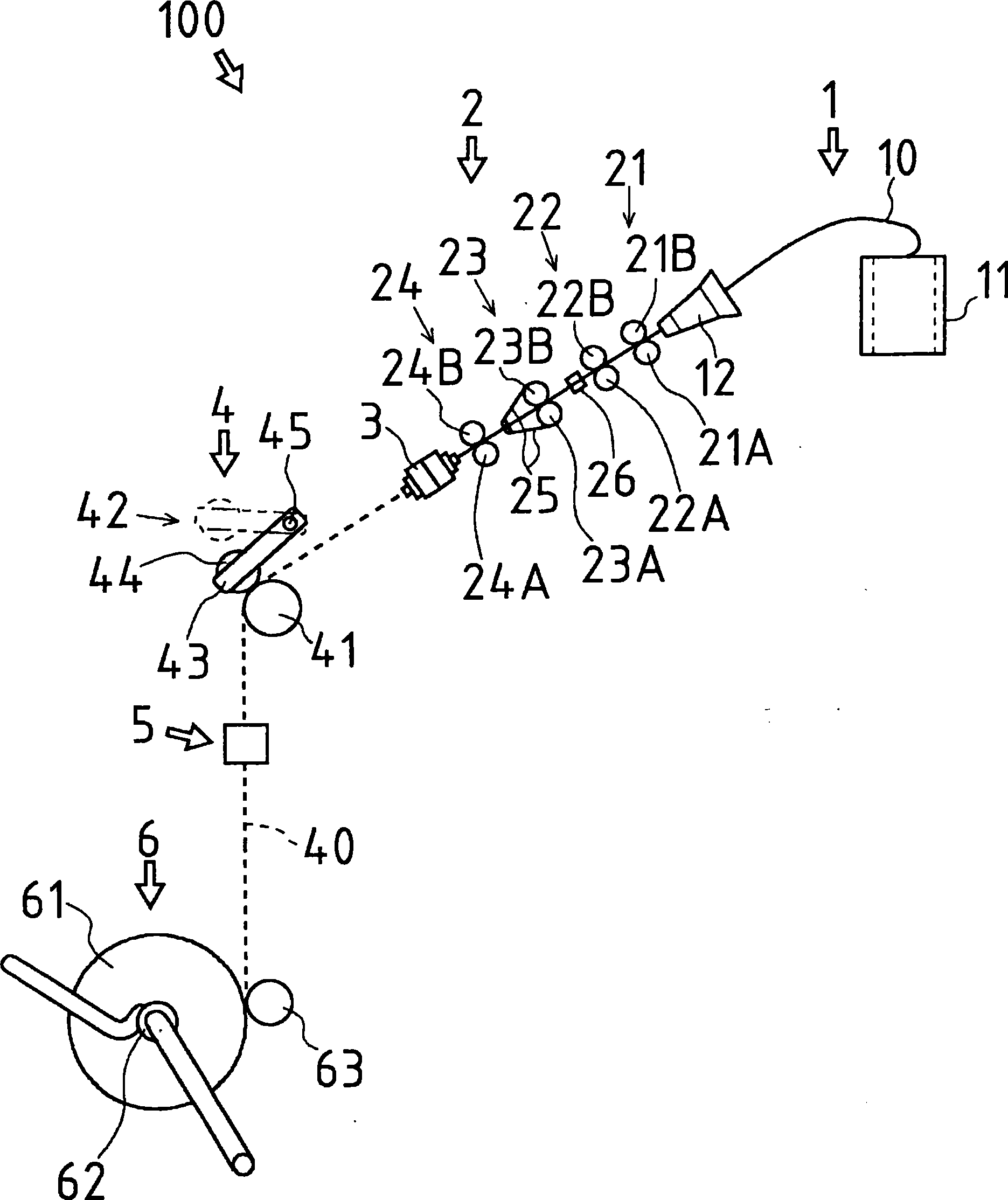

[0032] Next, a spinning machine 100 according to an embodiment of the present invention will be described with reference to the drawings.

[0033] figure 1 It is a side sectional view showing the spinning machine 100 according to the embodiment of the present invention.

[0034] The spinning machine 100 has a sliver supply unit 1 , a drafting device 2 , an air spinning device 3 , a yarn feeding device 4 , a yarn defect detecting device 5 and a winding device 6 .

[0035] The sliver supply unit 1 is composed of a sliver 10 as a raw material, a sliver box 11 for storing the sliver 10 , and a sliver guide 12 for guiding the sliver 10 to the draft device 2 .

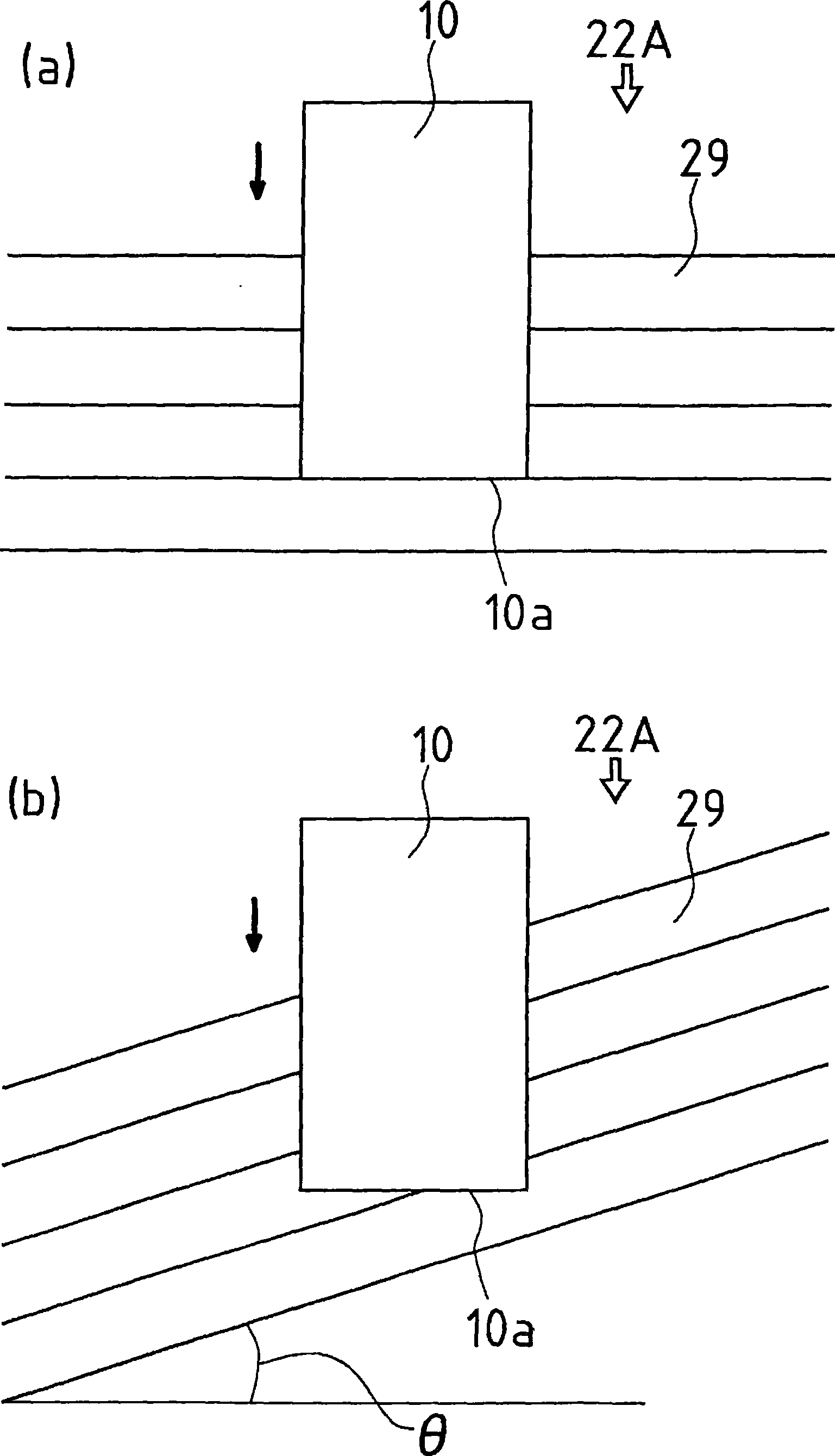

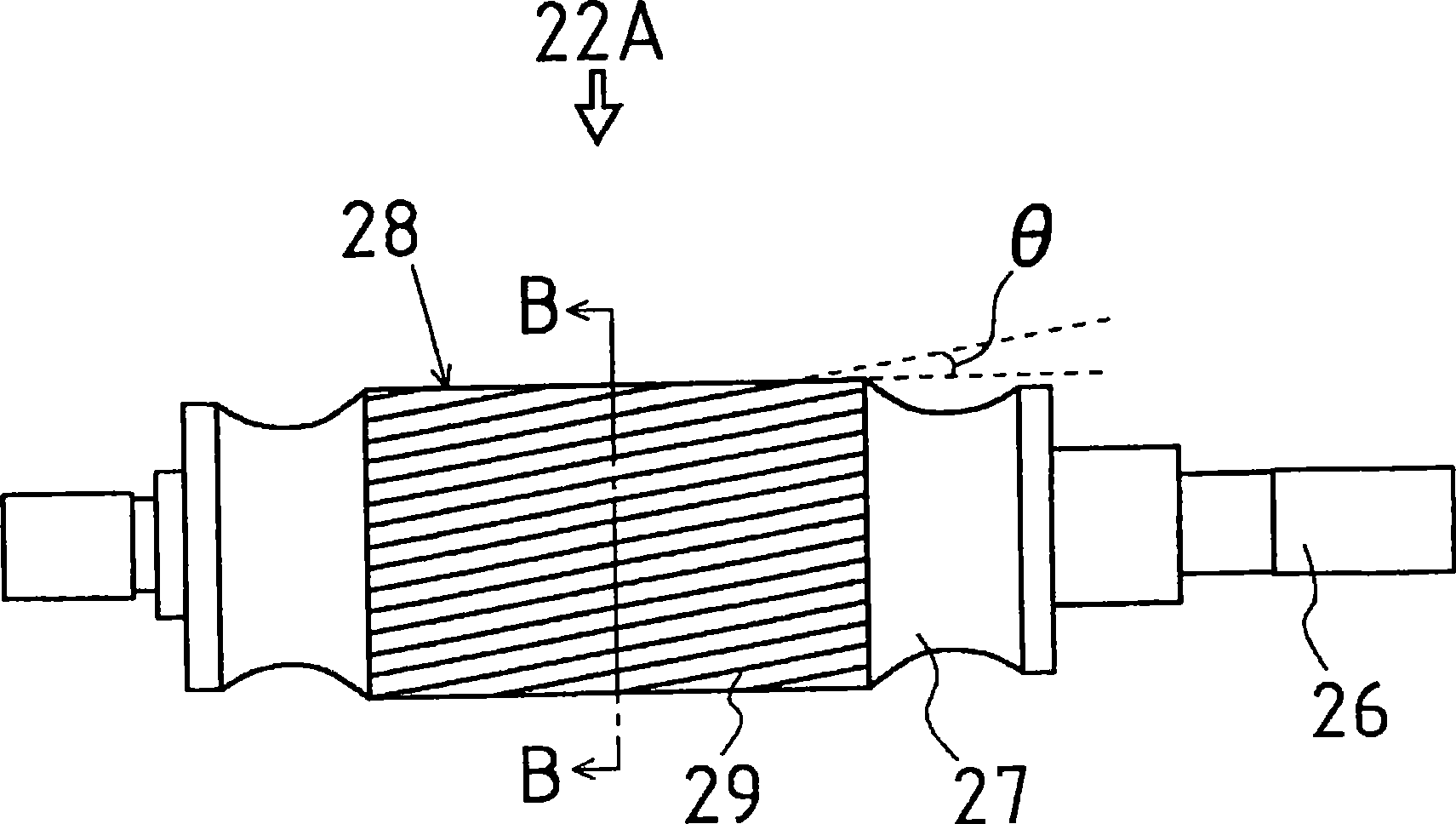

[0036] The drafting device 2 includes four pairs of drafting rollers that sandwich the sliver 10 and stretch it. The above four groups of drafting roller pairs are composed of a rear roller pair 21, a third roller pair 22, an intermediate roller pair 23 and a front roller pair 24, and each roller pair is arranged sequentia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com