Light collecting device and headlamp provided with light splitting structure

A light collection and headlamp technology, applied in the field of lighting, can solve the problems of unreliability and high manufacturing cost of headlamps, and achieve the effects of improving reliability, simple structure and uniform structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

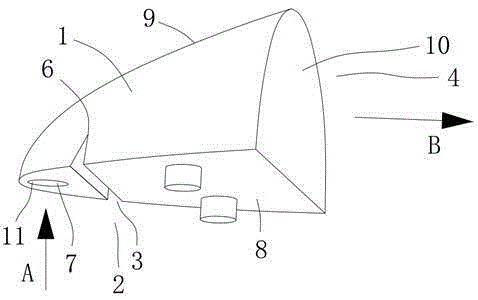

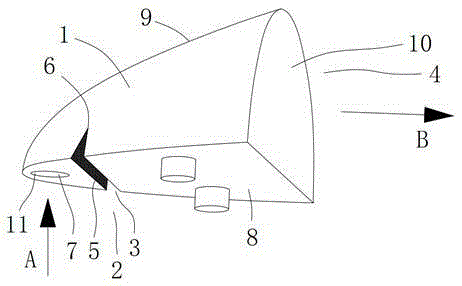

[0048] Example 2, such as figure 1 with 5 as shown,

[0049] As in the light collecting device described in Embodiment 1, a notch 3 is provided on the lens body, and the wall surface of the notch 3 serves as the light splitting structure 2 .

[0050] In the above scheme of the present application, the light collecting device is set as a lens body, the lens body is provided with a notch 3, and the wall surface of the notch 3 is used as the light splitting structure 2, that is to say, the light collecting device of the present application passes through the lens body. The wall is used as the light splitting structure 2, and part of the light emitted to the headlight projection device 12 is refracted or reflected by the wall surface of the lens body, so that the headlight projection device 12 projects a light distribution pattern that meets the requirements. Structure 2 has a better integration, which directly avoids the risk of relative position changes, further improves the r...

Embodiment 3

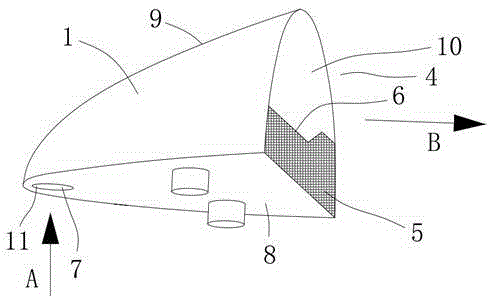

[0051] Example 3, such as image 3 with 5 or 4 and 5,

[0052] As in the light collecting device described in Embodiment 1, the lens body has an exit end 4, and the light emitted by the headlight light source 13 is collected by the light collecting device body 1 and emitted from the exit end 4, and then shot forward. In the lamp projection device 12 , part of the end surface of the emitting end 4 is the light splitting structure 2 .

[0053] In the above solution of the present application, part of the end surface of the exit end 4 of the lens body is used as the light splitting structure 2, which further facilitates the processing and manufacturing of the light collection device of the present application, and reduces the difficulty and cost of processing and manufacturing the light collection device.

Embodiment 4

[0054] Example 4, such as Figure 1-5 as shown,

[0055] In the light collection device according to any one of embodiments 1-3, the light splitting structure 2 reflects the light irradiated thereon back into the light collection device body 1, and the light reflected by the light splitting structure 2 passes through the The light collecting device body 1 collects it again and emits it to the headlight projecting device 12 .

[0056] In the above solution of the present application, the light reflected by the light splitting structure 2 is collected and utilized by the light collecting device body 1 again, which improves the utilization rate of the headlight light source 13, and then makes it possible to use the light source of the present application under the premise of obtaining the same light intensity. The advanced light collection device can reduce the power of the light source 13, while reducing the cost, it also reduces the calorific value of the light source 13, impr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com