Cyclic heating device for cloth roller of beam dyeing machine

A technology of cyclic heating and cloth rolling roller, which is applied in textile processing machine accessories, equipment configuration for processing textile materials, textiles and papermaking, etc., can solve the problems of color difference between head and tail, achieve the effect of eliminating color difference between head and tail, and solve the temperature difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

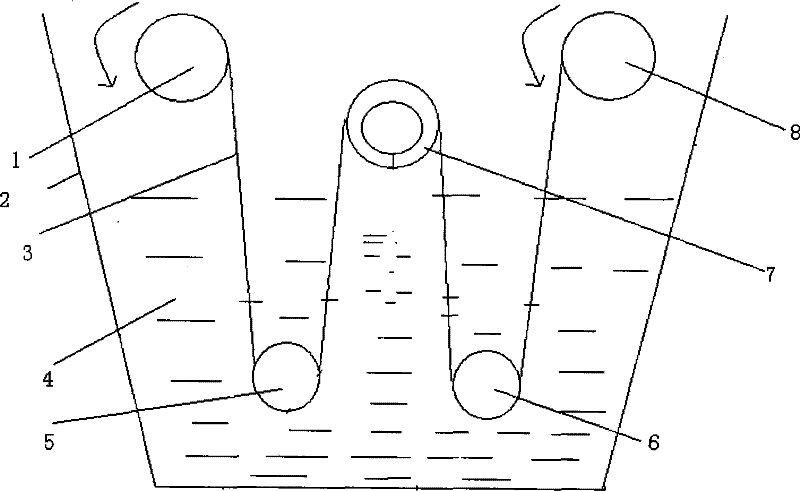

[0009] figure 1 It is a schematic diagram of the dyeing structure of a jigger in the prior art. The jigger includes a housing 2 in which the dye solution is located, and also includes a first cloth roll 1 and a second cloth roll 8 located at the upper end of the liquid surface. The first lower roller 5 and the second lower roller 6 inside the dye liquor are located between the first lower roller 5 and the second lower roller 6 and above the first lower roller 5 and the second lower roller 6 The force measuring roller 7, the pre-processed fabric 3 is rolled onto the second cloth roll 8, and then the cloth head passes through the second lower roller 6, the force measuring roller 7, and the first lower roller 5 to the first cloth roller 1 on.

[0010] When dyeing starts, the first cloth roll 1 rotates counterclockwise, and the first lower roller 5 and the second lower roller 6 are driven by the cloth. The force measuring roller 7 and the second cloth roller 8 rotate to make the clot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com