Automatic clamping system and detection method thereof

A detection method and automatic technology, applied in the configuration of indicating equipment/measuring equipment, manufacturing tools, metal processing equipment, etc., can solve problems such as difficult molding, affecting the dimensional accuracy of castings, and difficult air discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

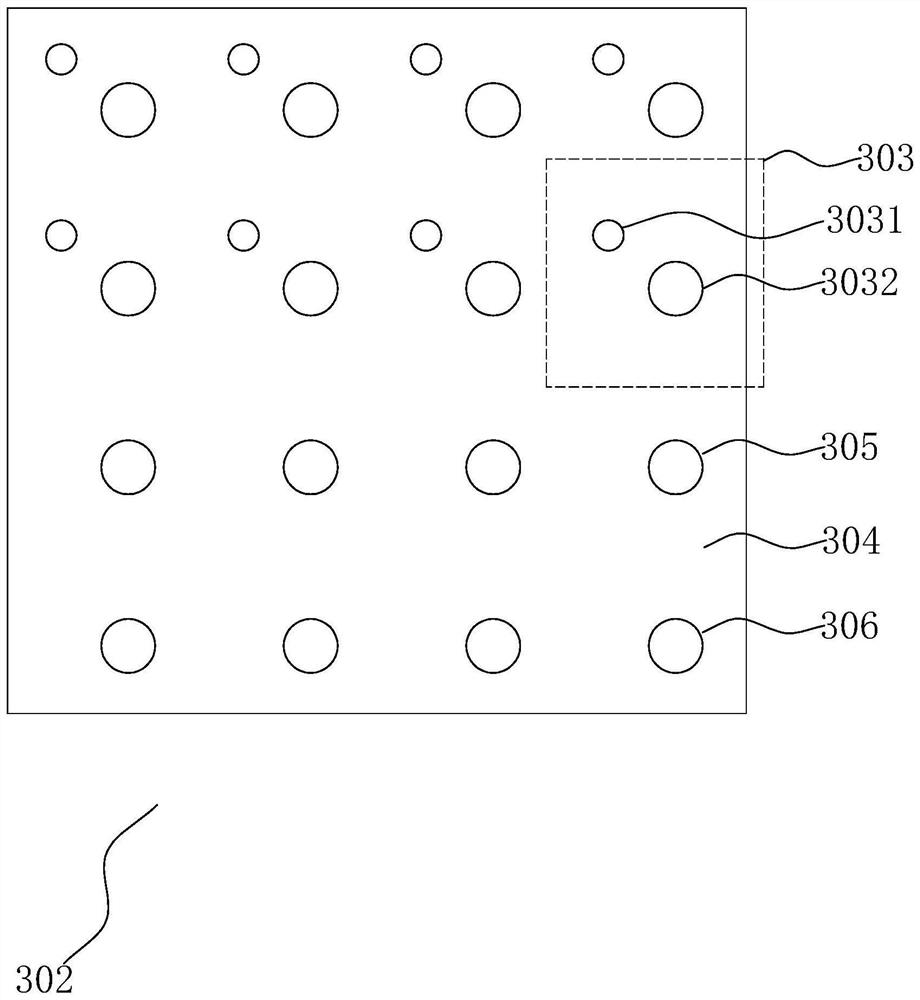

[0048] The following is attached Figure 1-6 The application is described in further detail.

[0049] The embodiment of the present application discloses an automatic clamping system.

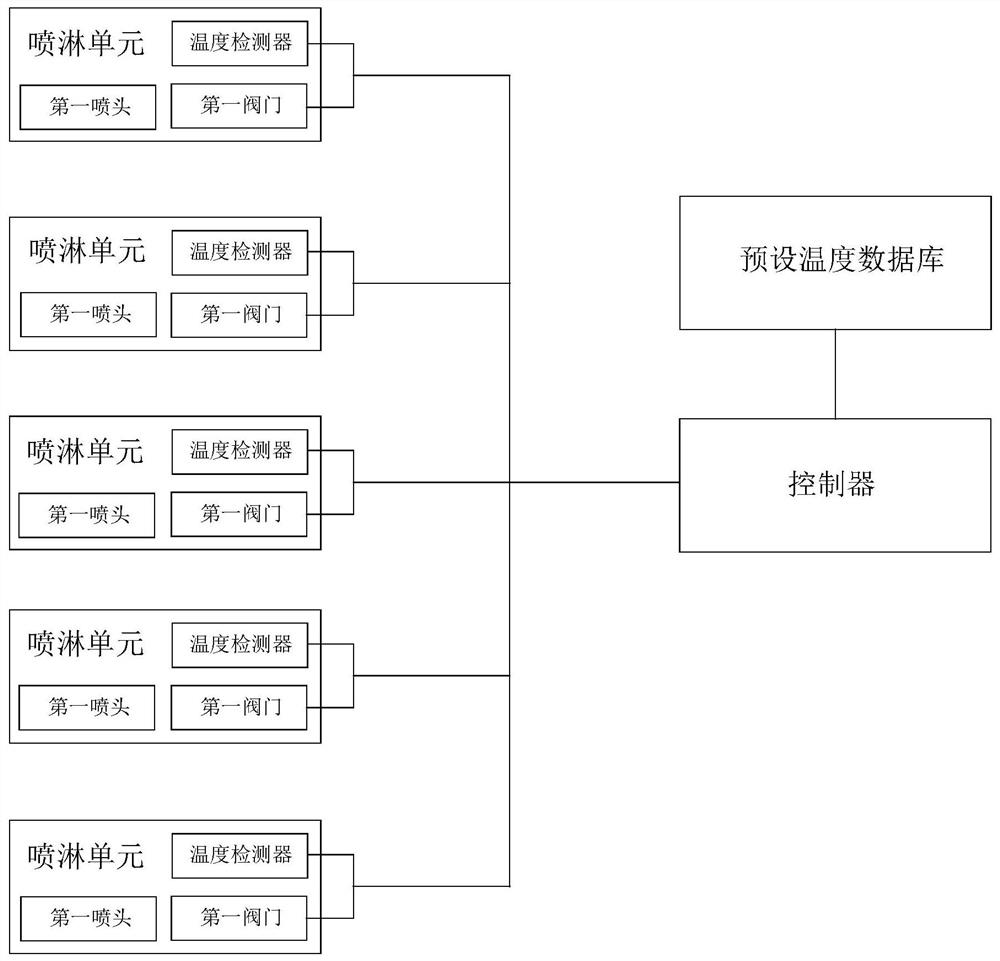

[0050] An automatic gripping system such as figure 2 As shown, including main rack, controller and preset temperature database. Applied to die casting machine.

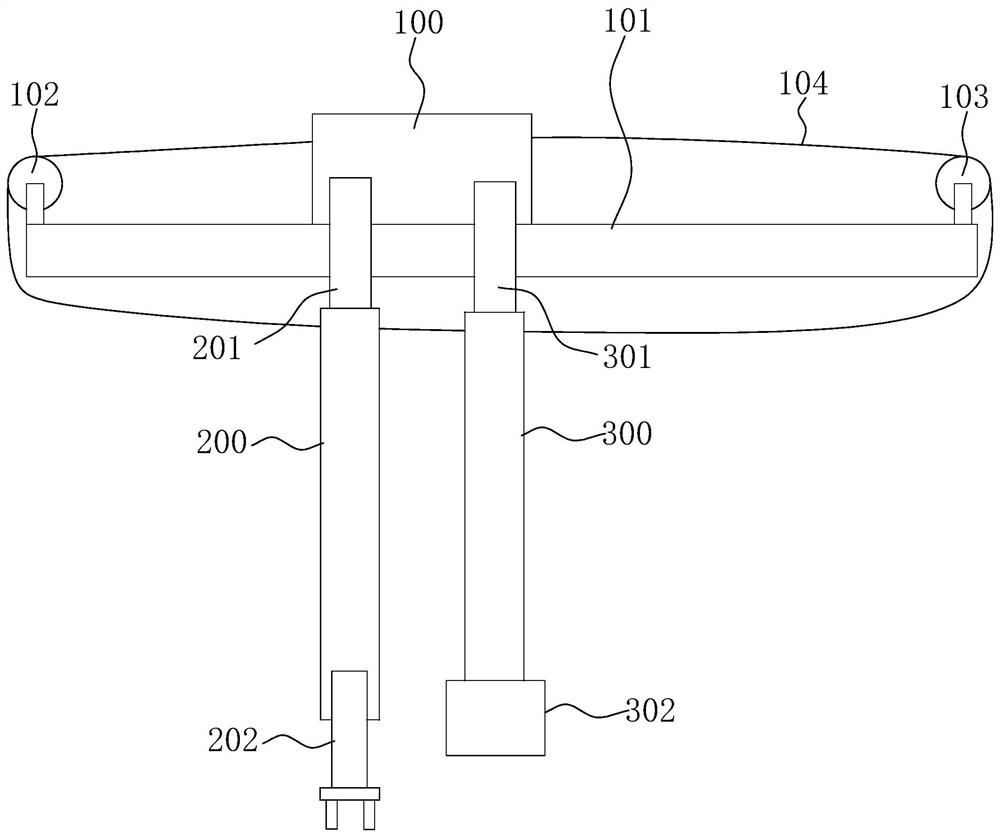

[0051] Such as figure 1 As shown, a drive assembly is provided below the main frame 100, and the drive assembly includes a horizontal guide rail 101 arranged below the main frame 100. The guide rail 101 is fixed on the wall so that the main frame 100 can move on the guide rail 101. One end is provided with a first gear 102, and the other end of the guide rail 101 is provided with a second gear 103, and a chain 104 is connected between the first gear 102 and the second gear 103, and one end of the chain 104 is fixed on the main frame 100 near the first gear. One end of the gear 102, the chain 104 meshes through the first gear 102,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com