Arrangement in connection with the press section of a web-forming machine

A forming machine and press section technology, applied in the press section, paper machine, calender, etc., can solve the problems of reduced web whiteness, opacity, web delamination, etc., to improve surface quality and initial smoothness , effective drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

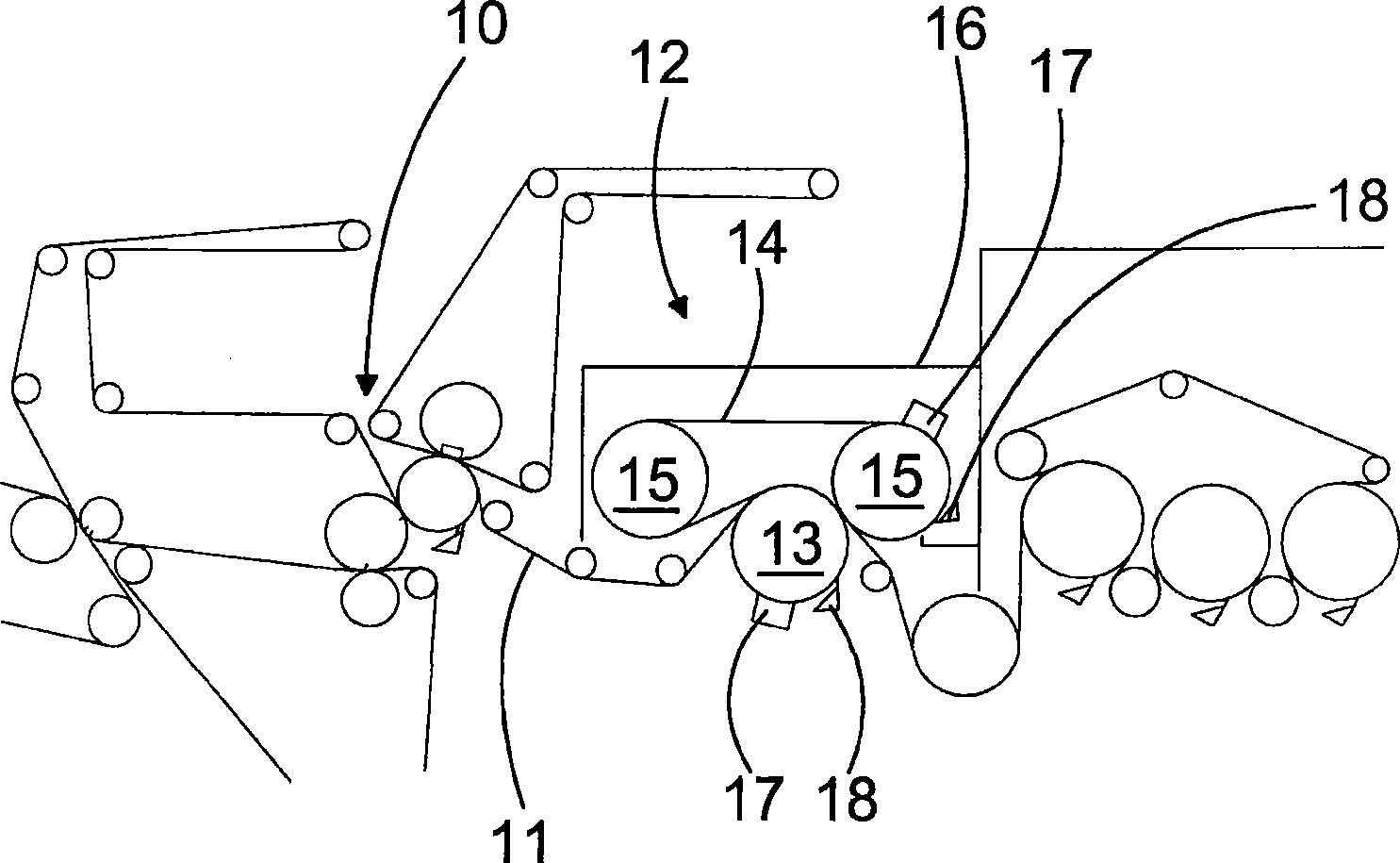

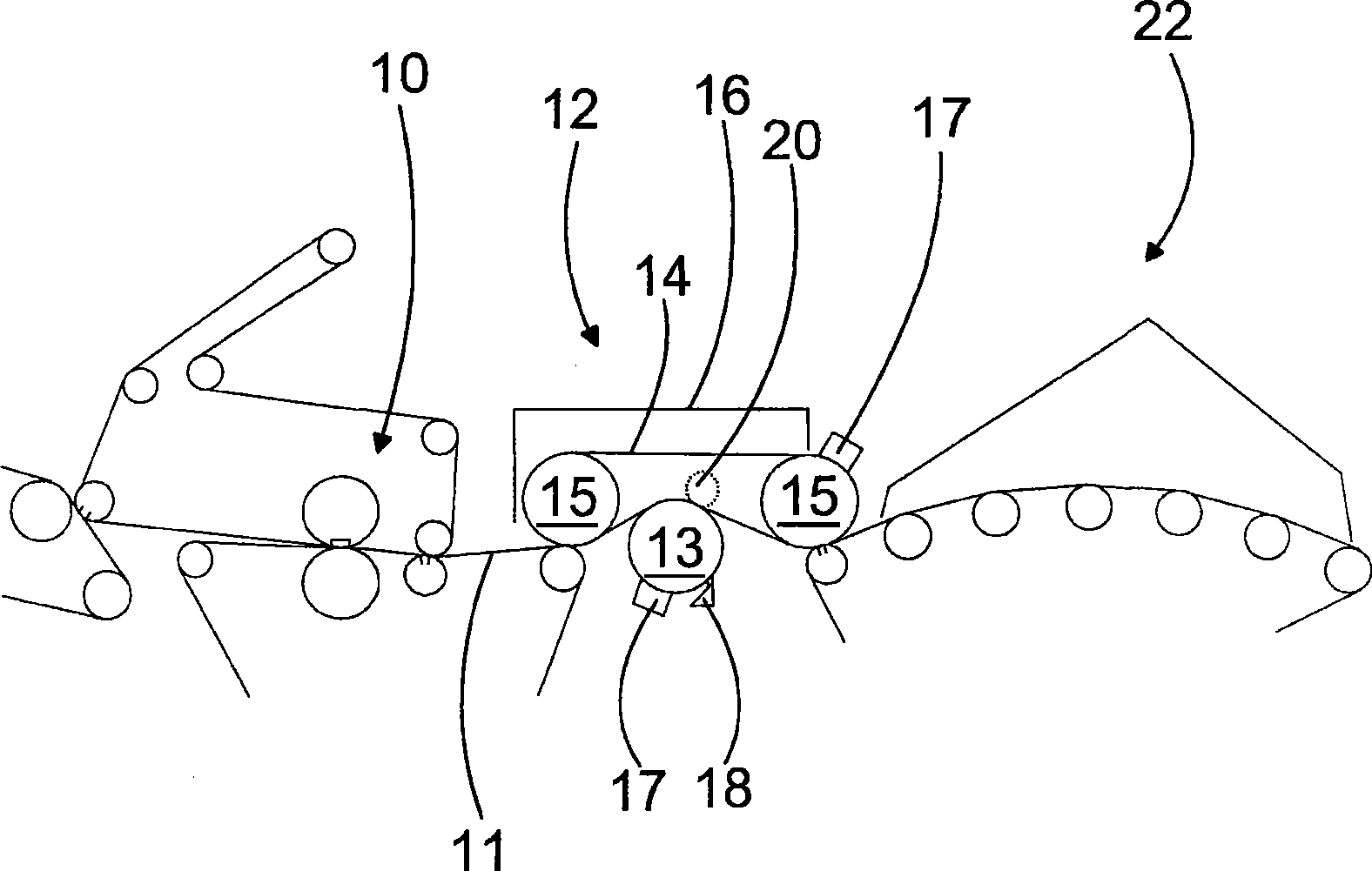

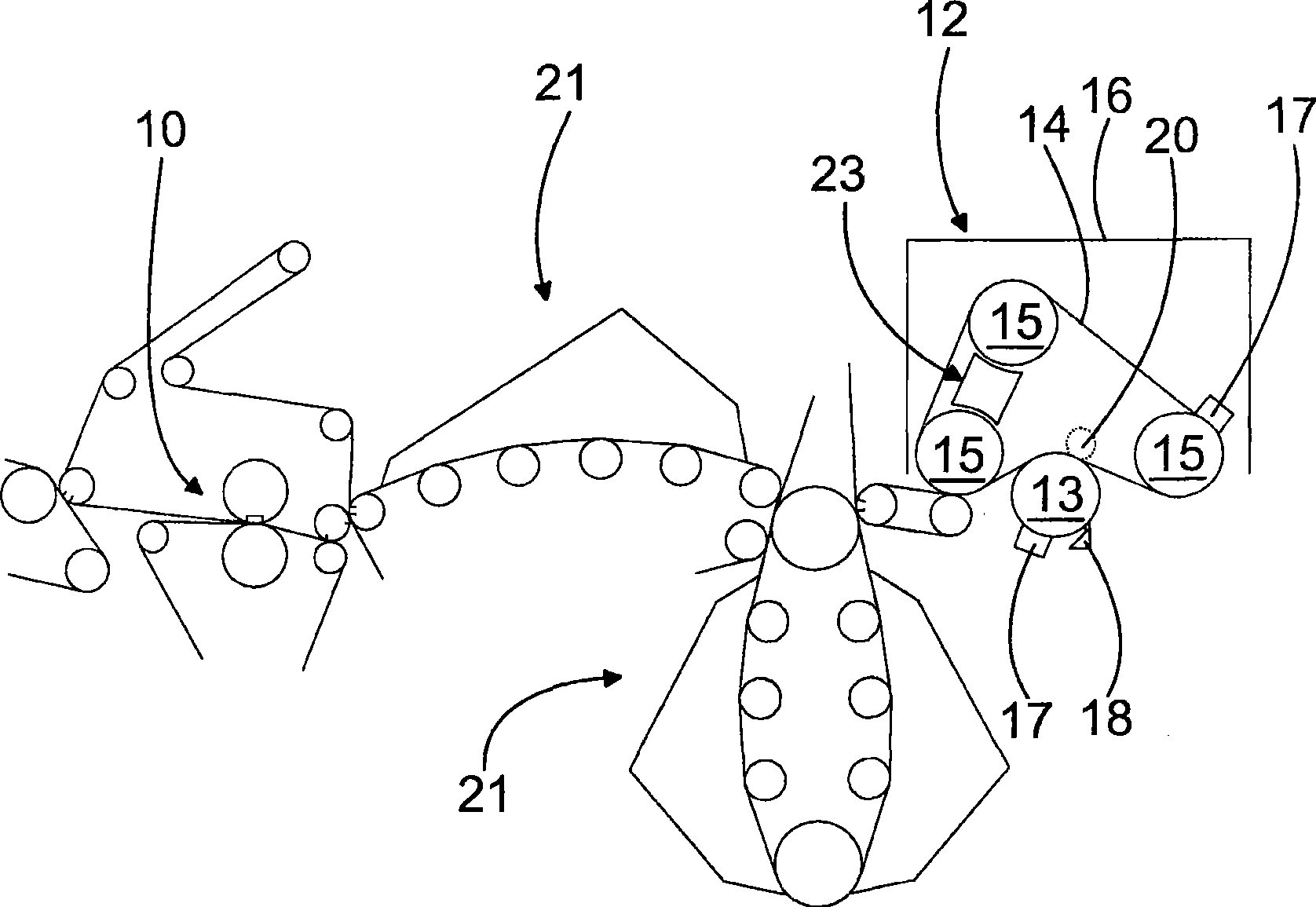

[0011] Figures 1a-2b Some equipment related to the press section of a web forming machine according to the invention is shown. The apparatus comprises at least one press nip 10 for dewatering a web 11 produced on a web forming machine. exist Figure 1a , actually has three press nips. The plant also comprises a smoothing press 12 comprising smoothing rolls 13 . Smooth rolls 13 are arranged after the press nip 10 . When reaching the smoothing press, before the can dryer section, the dry matter content of the web is above 45%, preferably above 55%. According to the invention, the smoothing press 12 also comprises a smoothing heating carrier 14 ′, such as a belt 14 . Preferably, the band is partly or completely made of metal. This metal strip is smooth and has no void volume for moisture removal. The belt 14 is arranged as a loop around at least two guide rollers 15 . The smoothing roller 13 is then arranged in contact with the belt 14 between two guide rollers 15 . Thus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com