Plug structure

A plug and socket body technology, applied in the field of plug structure, can solve problems such as tip discharge, insertion angle deviation, disasters, etc., and achieve the effect of increasing service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The embodiments of the present invention will be described in more detail below in conjunction with the accompanying drawings, so that any worker who is familiar with the technology can implement it after studying the specification.

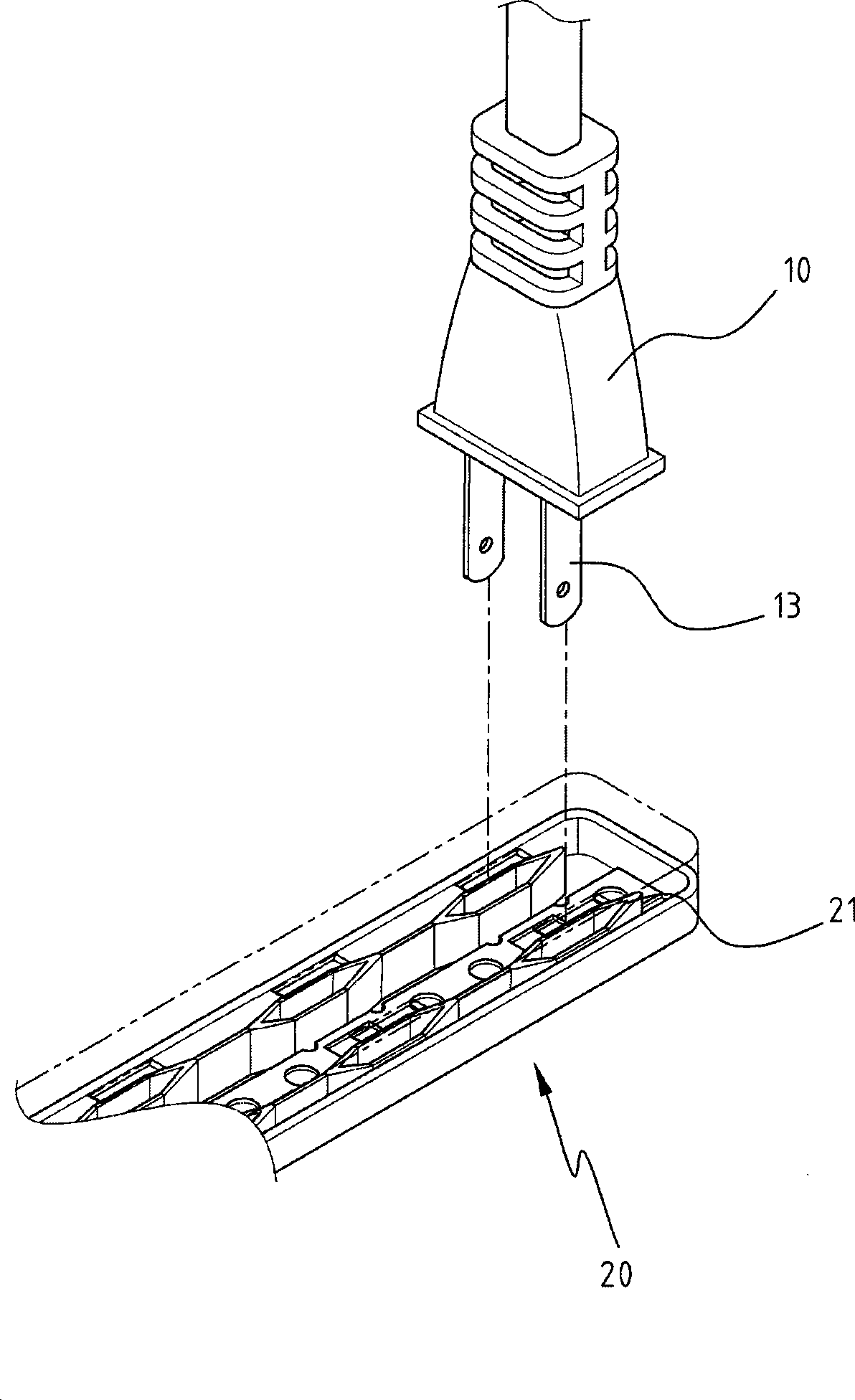

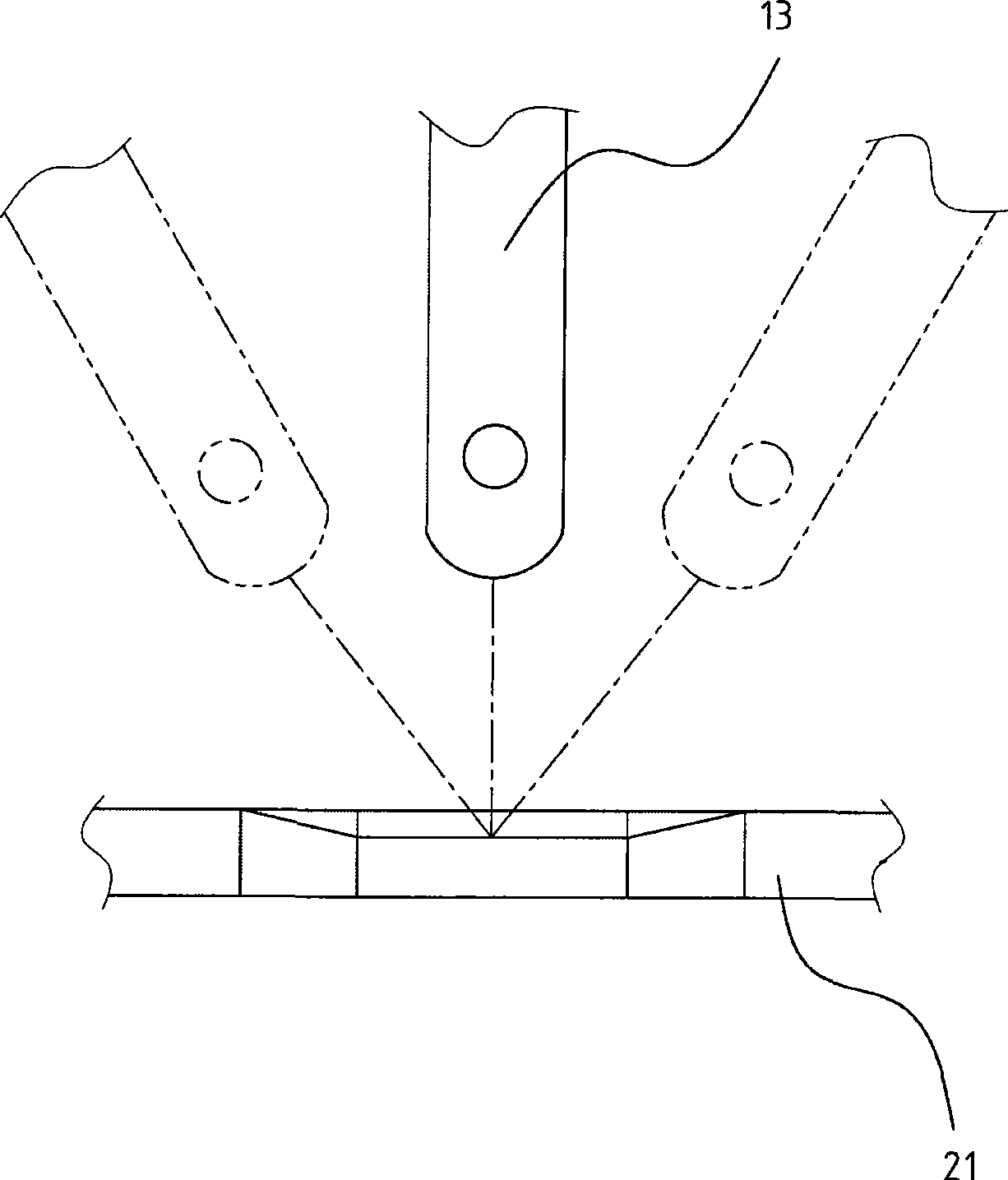

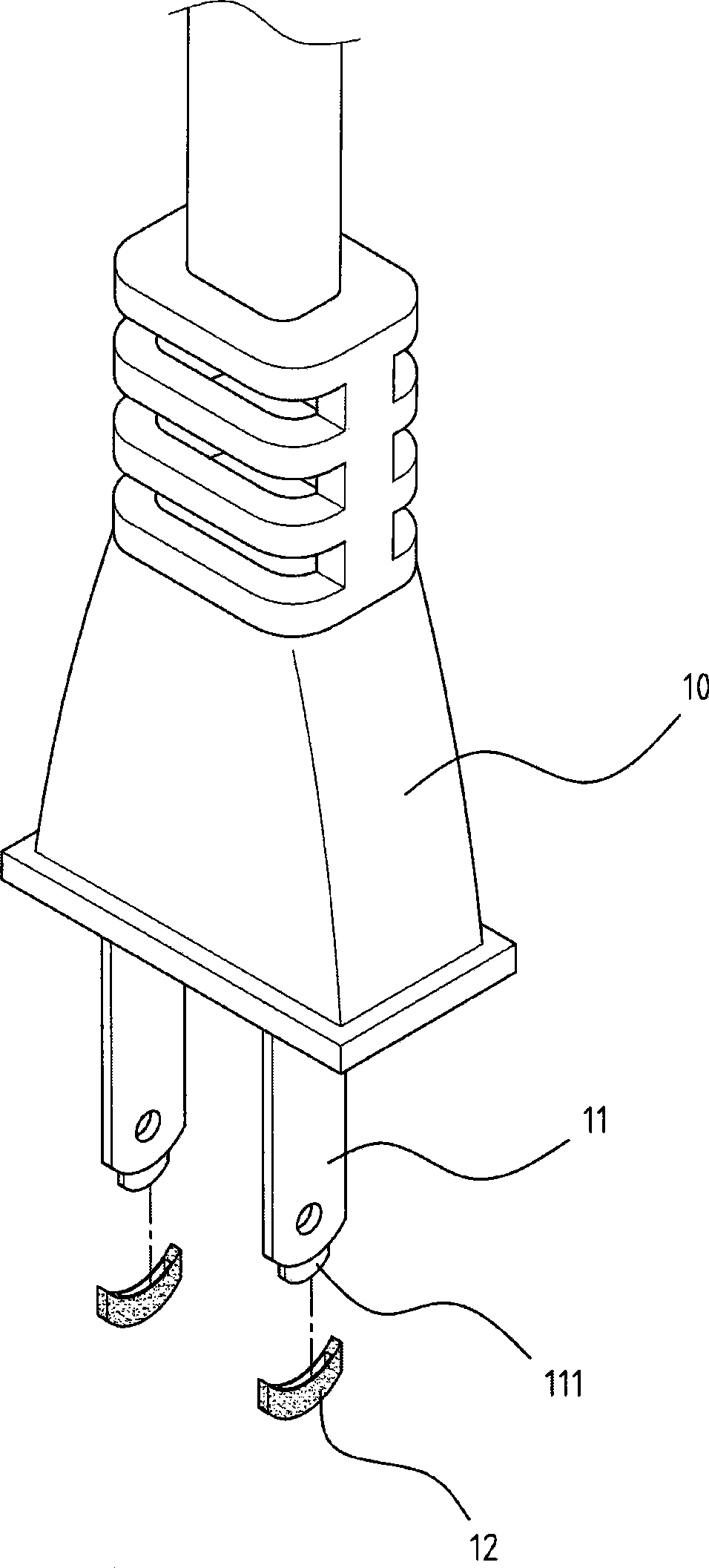

[0033] Please see Figure 3A As shown in the schematic assembly diagram of the structure of the present invention, the plug structure of the present invention has a body size regulated by standard specifications, but according to the plug specifications of various countries, there will be different specifications; Figure 3A It is the standard specification, and the main design feature of the present invention is that the end of the conductive terminal 11 provided on the plug body 10 that is inserted into the power socket 20 is provided with a protruding body whose volume is smaller than the size of the original specification, thereby generating sufficient The space is provided for a certain amount of insulating material to be covered on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com