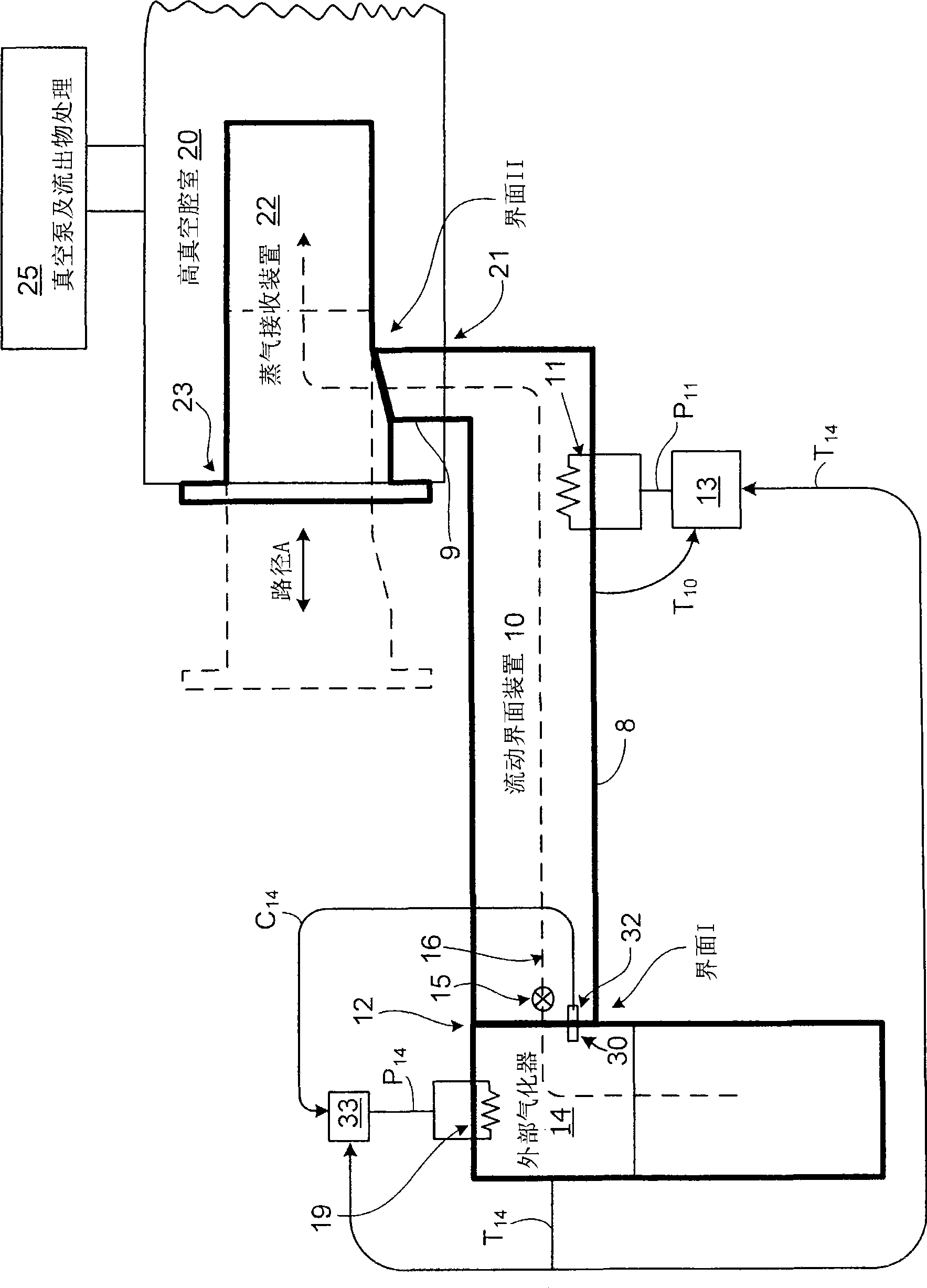

Vapor delivery system useful with ion sources and vaporizers for use in such system

A vaporizer, ion source technology, used in drum brakes, brake types, mechanical equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

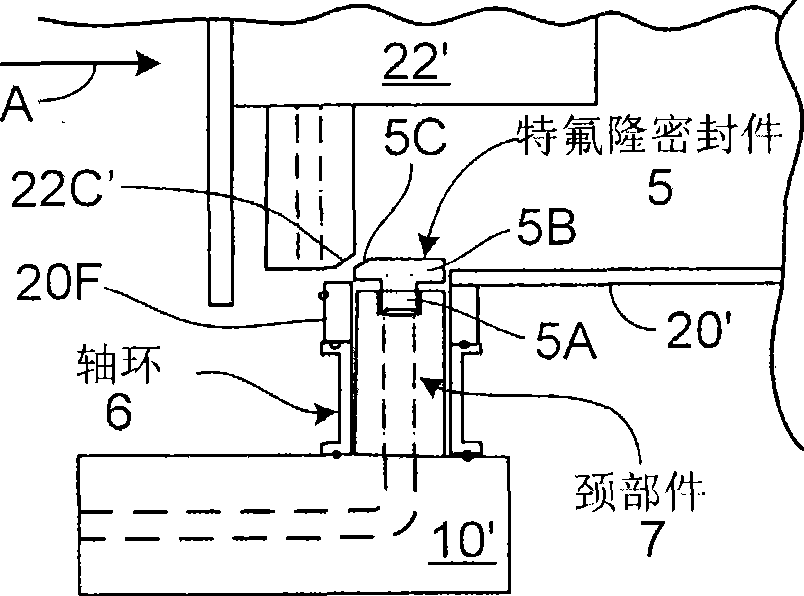

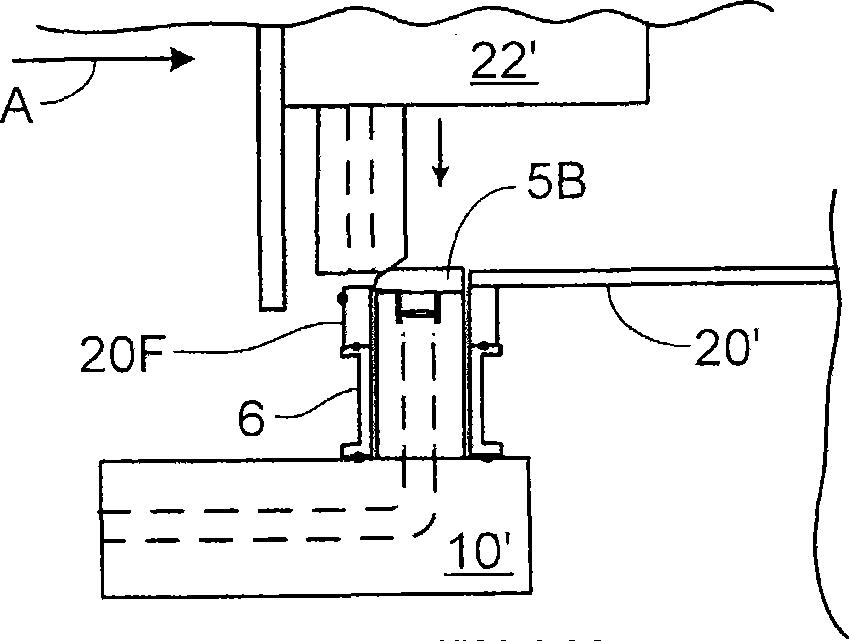

Method used

Image

Examples

example : example 1:1 and 2, or 3 and 4。 example 2

[0156] The tight controls required to prevent mixing of hazardous vapor combinations for enabling flow from the gasifier can be subordinated to pre-established protocols implemented by the control logic in the electromechanical control system. Similarly, mechanical interlocks may have provisions for changing modes of operation. In some cases, controls are established that absolutely prevent communication between gasifiers or between selected gasifiers. On the other hand, the control may implement the allowance of simultaneous flow for certain gasifiers. This is appropriate and applicable where the gasifier contains the same feed material. For example, simultaneous flow can be used when the charge in one gasifier is approaching depletion, and although there is a need to utilize the entire charge for economic reasons, it is also necessary to start using an alternate gasifier. This strategy has the advantage of ensuring an adequate supply of vapor without pushing the heating li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com