Blended knitting wool pearl yarn and technique for processing the same

A technology of blending yarn and wool, applied in the field of wool spinning, can solve the problems of inability to meet various levels of people, lack of sensory effects, monotonous products, etc., and achieve the effect of rich appearance style, fluffy hand feeling and clear texture.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be further described below in conjunction with the examples.

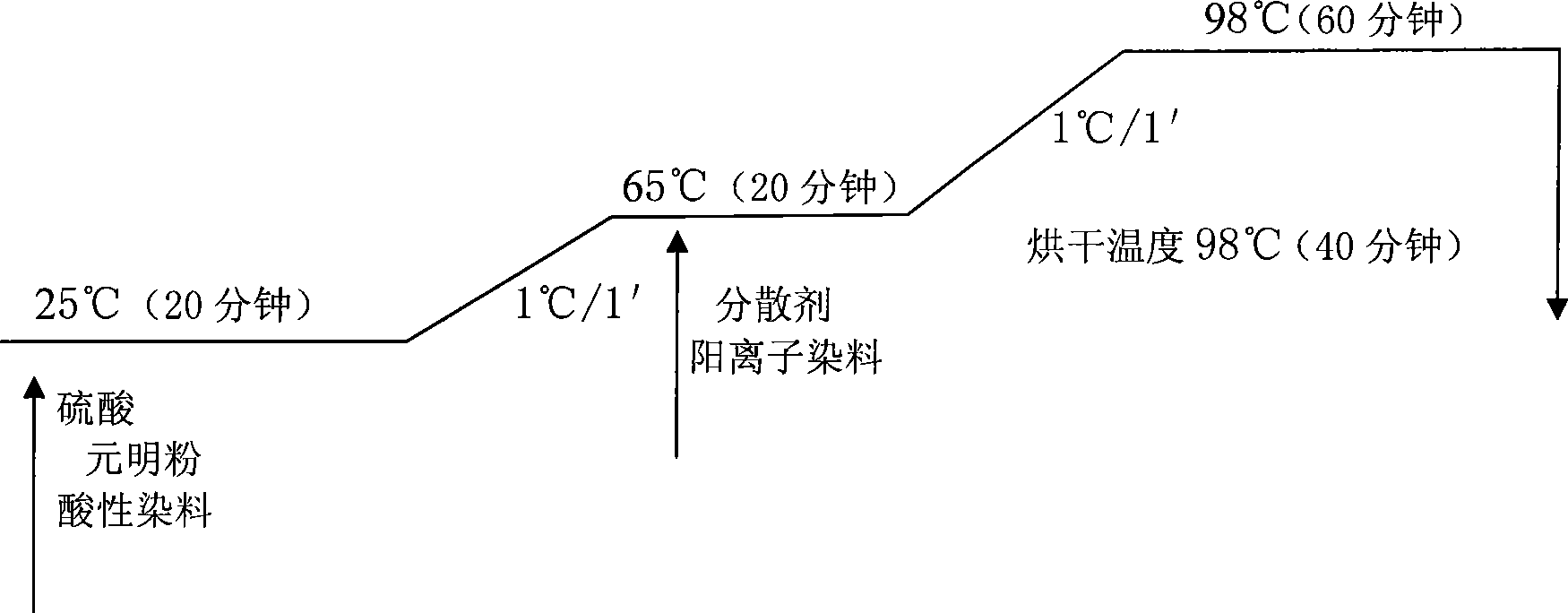

[0025] The blended yarn AB pearl yarn of the present embodiment, the A yarn is the blended yarn of 56 mercerized Australian hairs (shrinkage rate 12%) and 3.3dtex conventional shrinkage rate (shrinkage rate 4%) acrylic fibers, and the blending weight percentage is 80:20; B yarn is a blended yarn of 56 counts of mercerized Australian wool (shrinkage rate 12%) and 3.3dtex high shrinkage rate (shrinkage rate 28%) acrylic fiber, and the blending weight percentage is 80:20. The specific process is as follows:

[0026] (1) Pre-spinning process: as shown in the table below.

[0027]

process

Device model

combined root number

Understretch

multiple Strip weight

(g / 10m)

mixed

Italy

SC400 / 11VA Hair: 8

Sunny: 2

8.3

24±1

a needle comb

Italy

SC400 / 11VA

8

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com