Premixing pre-vortex plasma assistant lighter

A technology of plasma and igniter, applied in the direction of burner, burner, burner ignition device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

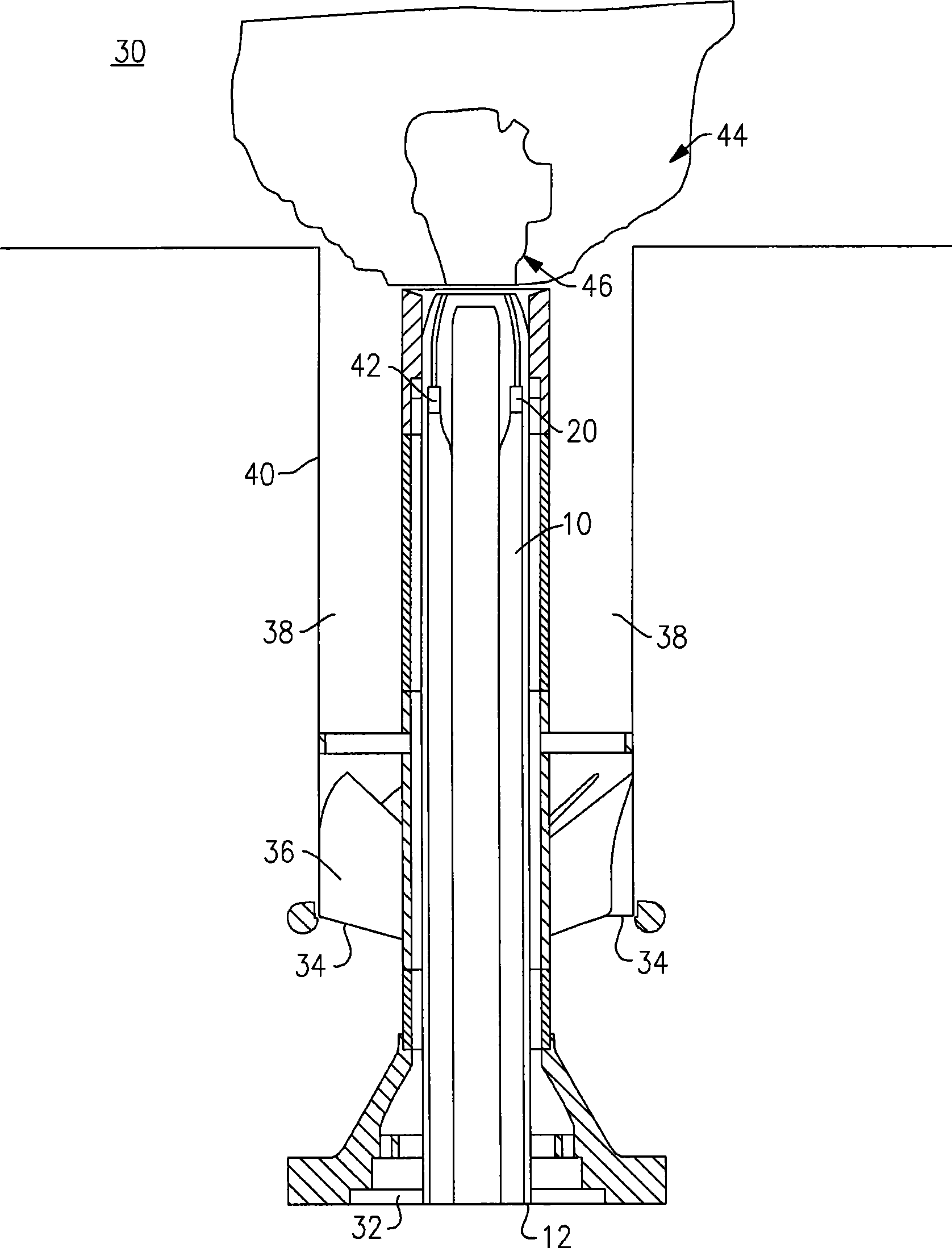

[0058] Here, the embodiments described hereinafter with reference to the drawings are directed to a pilot burner comprising means for swirling air and fuel or a fuel / air mixture to provide pre-mixing pre-swirling plasma assist ( Enhanced) a pilot flame suitable for use with a gas turbine combustor. According to one embodiment, the pilot burner is located in the center body of a premixed fuel / air nozzle of a gas turbine combustor and operates to improve the lean limit of blowout (LBO) of the combustor. Pilots may also, but are not limited to, operate as a source of ignition and / or as a means of reducing combustion instabilities.

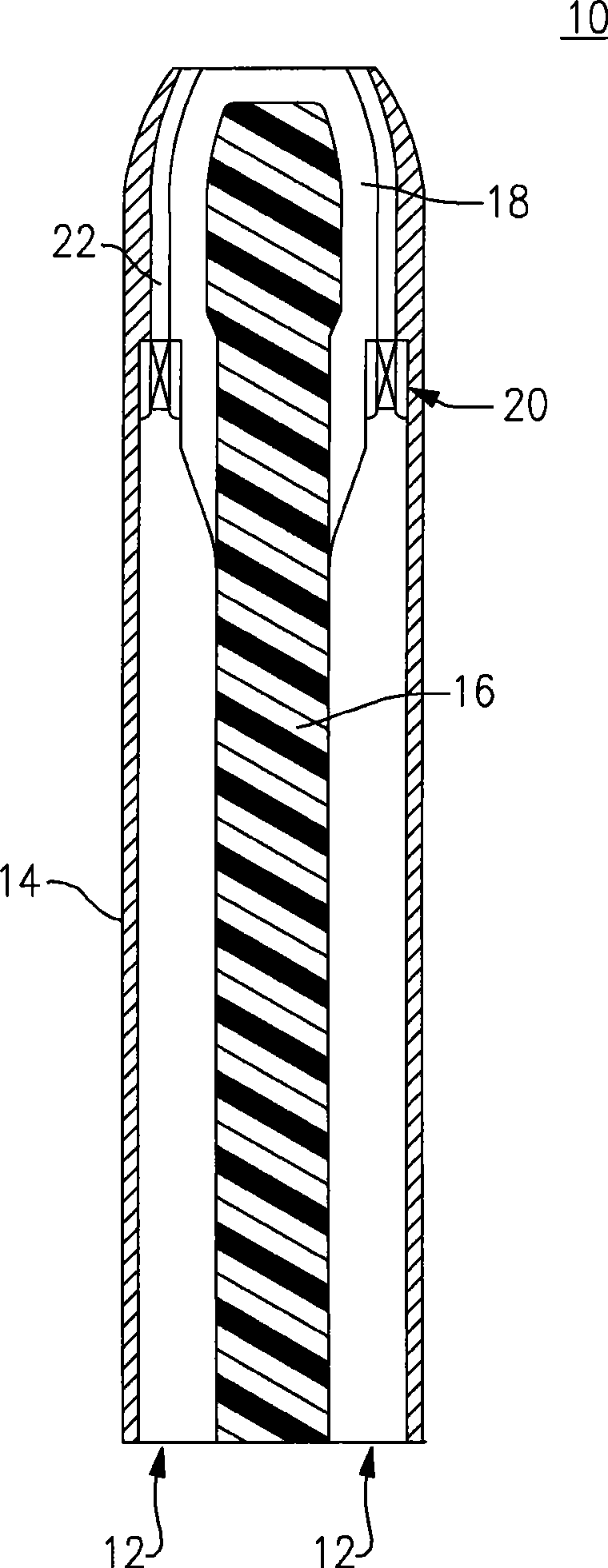

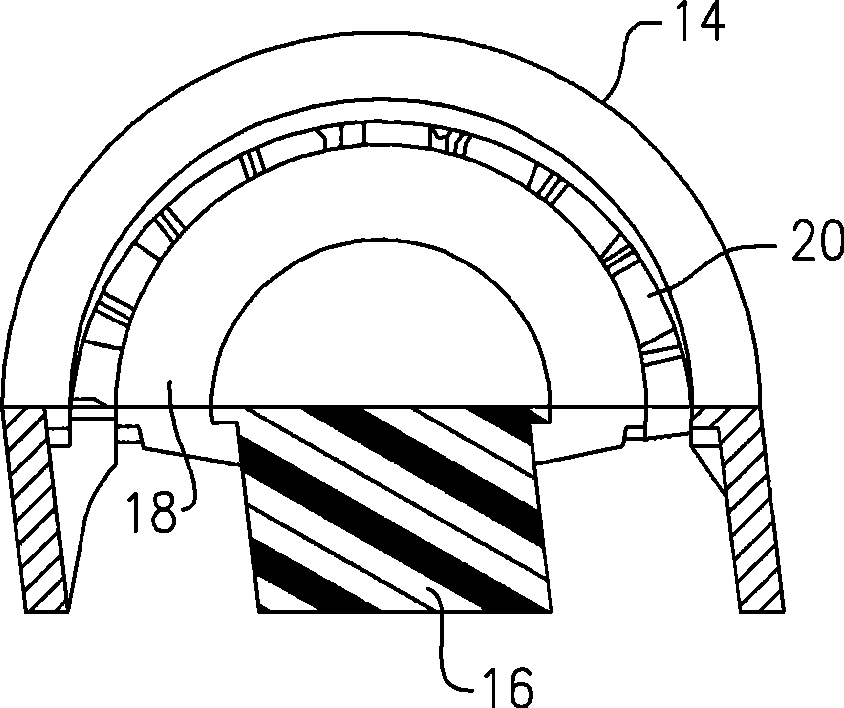

[0059] look now figure 1 , a side cross-sectional view diagrammatically shows a premixed prevortex plasma assisted pilot burner 10 in accordance with one aspect of the present invention. The pilot burner 10 includes a swirler arrangement 20 to induce swirling of the air and fuel or fuel / air mixture entering the pilot burner 10 through one or more in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com