Transfer printing component of image forming apparatus and image forming apparatus

A technology for transferring parts and images, which is applied in the direction of electric recording process applying charge pattern, equipment and apparatus of electric recording process applying charge pattern, etc. The layer effect is damaged, and it is difficult to achieve high image quality. It can suppress the charging phenomenon, be less prone to cracks, and achieve the effect of image quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

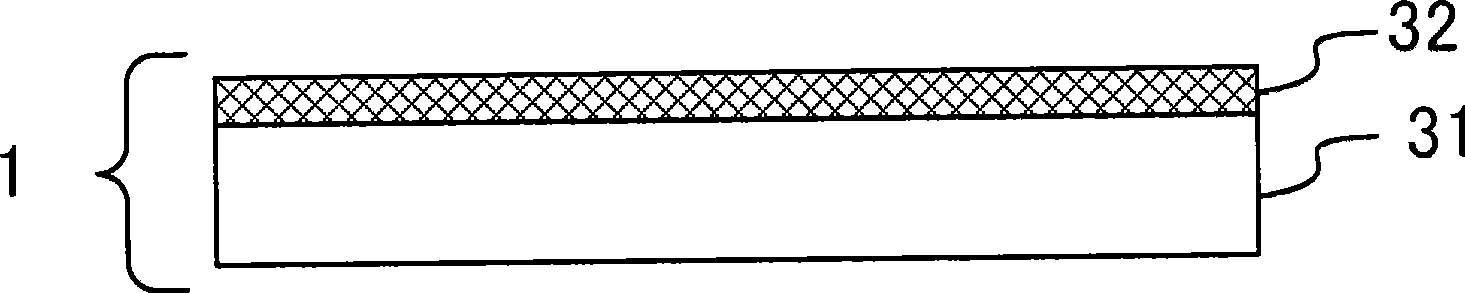

[0097] (Example 1: the surface layer adopts the situation of resin dispersed with diamond particles)

[0098] As the above-mentioned diamond fine particles, for example, products manufactured by NEW METAL AND CHEMICALS CO., LTD. or Sumitomo Carbonyl Mining Co., Ltd. can be used. If the diamond particles are manufactured by blasting, there are many impurities and the particle size distribution is relatively wide, so concentrated sulfuric acid is generally used to clean them.

[0099] In addition, there is also a method of synthesizing from graphite using a high-pressure, high-temperature device, but in the embodiments of the present invention, pre-refined diamond particles are used, so the particle preparation process is omitted. These diamond particles can be dispersed in fluorine-based resins such as PFA or PTFE. Furthermore, since it is used as a transfer material, a conductive agent such as carbon can also be dispersed at the same time if necessary.

[0100] The content o...

Embodiment 1a

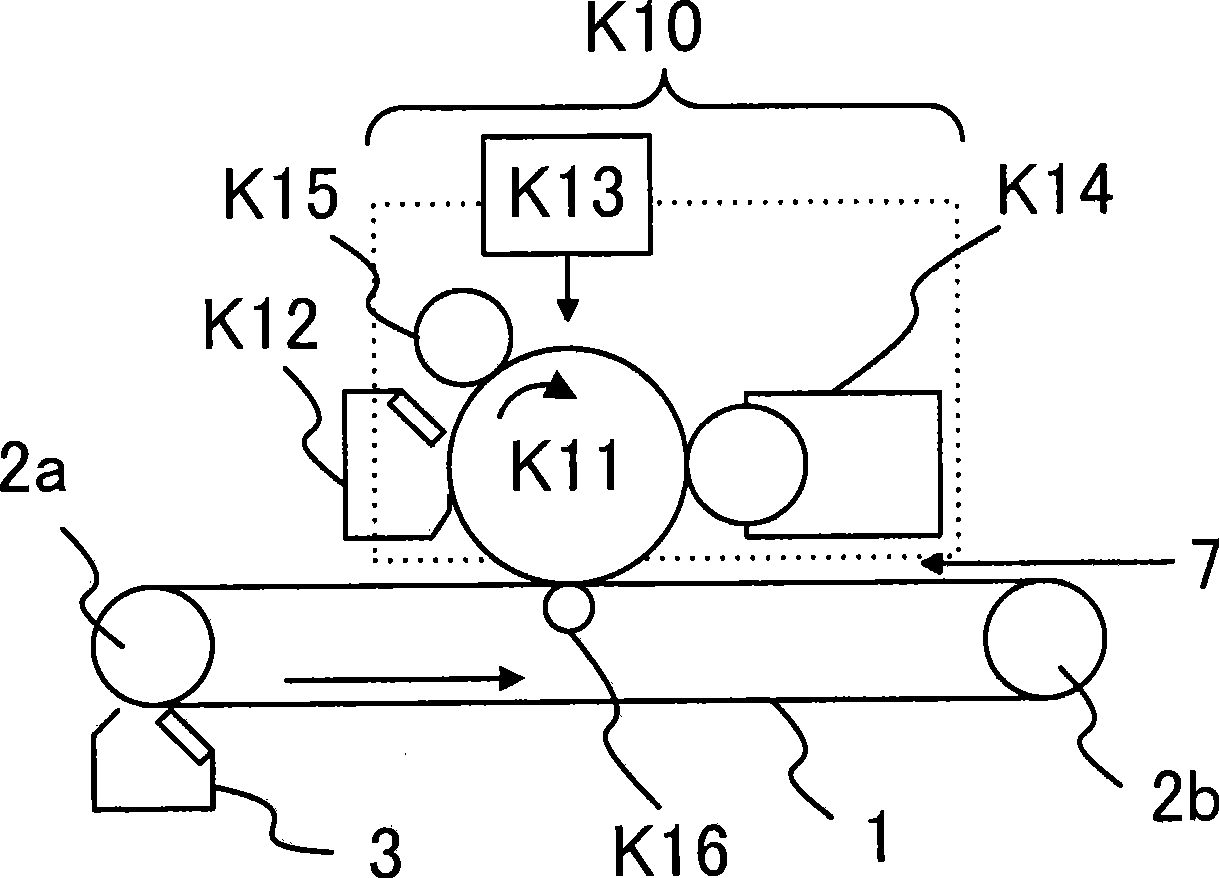

[0103] (Example 1a: When the present invention is applied to a transfer belt of a direct transfer method)

[0104] exist figure 1 In the configuration of the image forming apparatus shown, a durability test was carried out in a state where development was performed without using toner, and in a state where paper was not passed. Furthermore, once every 1k sheets of paper, a halftone image with an area ratio of 50% was printed on the belt, and the cleaning performance of the belt cleaner was confirmed. At this time, the toner on the cleaned tape was extracted with a mending tape, and the reflection density when the adhesive tape without the toner was attached to white paper was judged to be different from that of the adhesive tape with the toner extracted. Whether the difference between the reflection densities of the bands is maintained at no higher than 0.05.

[0105] Reflection density was measured with a Macbeth densitometer. Randomly measure in five places, as long as on...

Embodiment 1b

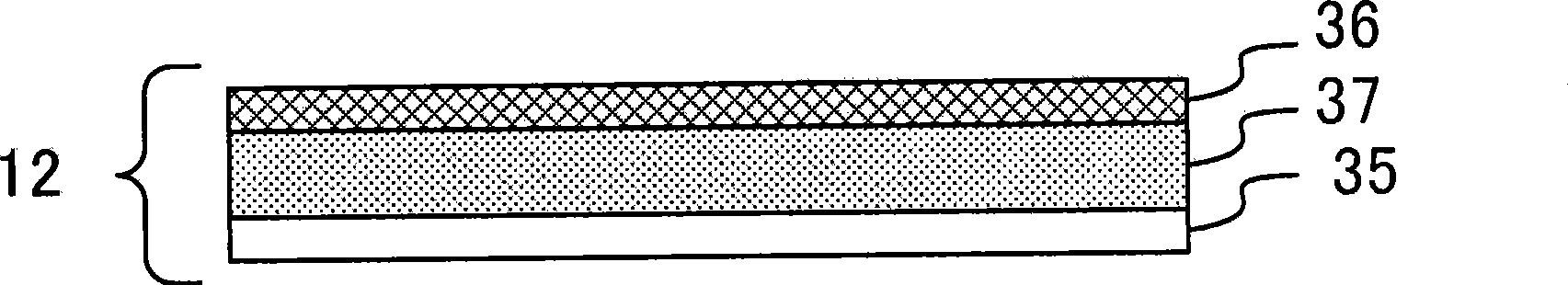

[0120] (Example 1b: When the present invention is applied to an indirect transfer belt of an indirect transfer method)

[0121] The above tests were carried out in the figure 1 The configuration shown is performed in a monochrome image forming apparatus. Also, as mentioned above, transfer printing with rubber substrates is mostly used for monochrome structures. Obviously, as long as the chromatic aberration etc. can be accurately controlled, the transfer belt of this constitution can also be used for such as figure 2 The effect of the present invention is also the same as that of the color image forming apparatus having the configuration shown above.

[0122] Moreover, especially in a tandem color image forming apparatus, since the distance between the stages of each color is short, the charging of the belt surface is a serious problem. Also in this case, even if the surface layer using diamond particles is thinner than the conventional fluorine layer, durability can be ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com