Control method for production according to self-defined production original record

A technology of original recording and control methods, applied in electrical program control, program control in sequence/logic controllers, etc., can solve the problems of data production operation time delay, reduced efficiency, and the inability to realize real-time monitoring of key technical parameters, etc. Achieve the effect of ensuring accuracy, ensuring product quality, saving management costs and labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

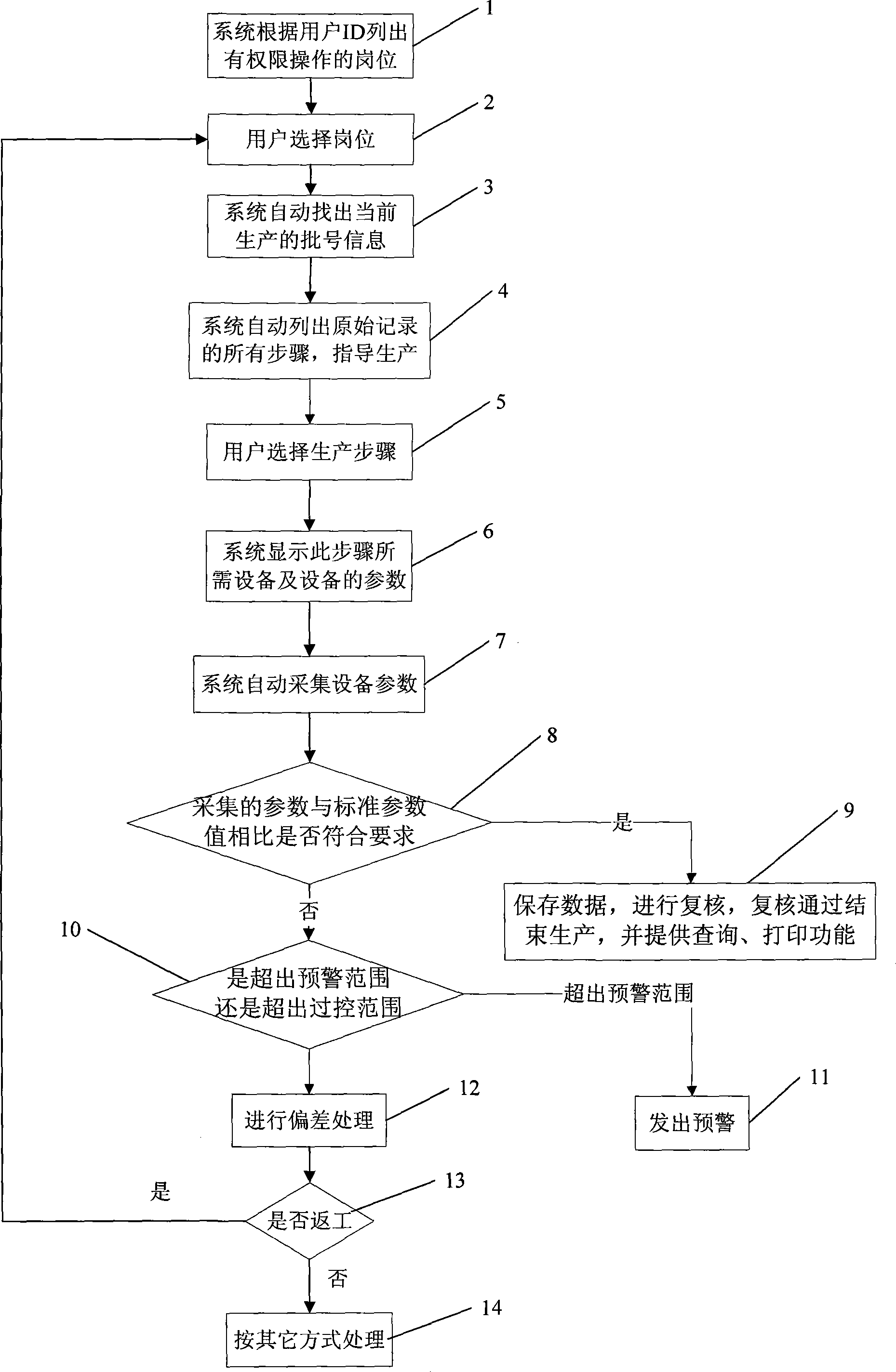

[0024] Such as figure 1 Shown, in the control method that the present invention carries out production according to self-defined production original record, step 1 is initial step, and the system lists the post that has authority to operate according to user ID; In step 2, the user selects post; In step In step 3, the system automatically finds out the batch number information of the current production; in step 4, the system automatically lists all the steps in the original record to guide the production; in step 5, the user selects the production step; in step 6, the system displays the step Required equipment and equipment parameters; in step 7, the system automatically collects equipment parameters; in step 8, detects whether the collected parameters meet the requirements compared with the standard parameter value, if the detection result is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com