Semiconductor encapsulation conformation throwing in multi-sinuosity connection finger

A semiconductor, zigzag connection technology, applied in the direction of semiconductor devices, semiconductor/solid-state device parts, electric solid-state devices, etc., can solve the problems of false contact of adjacent contacts, electrical short circuits, and different sizes of wafers in arrangement positions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] In order to further explain the technical means and effects that the present invention adopts to achieve the intended purpose of the invention, below in conjunction with the accompanying drawings and preferred embodiments, the structure of a semiconductor package with multiple twists and turns for wire bonding proposed according to the present invention will be described in detail. Embodiments, structures, features and effects thereof are described in detail below.

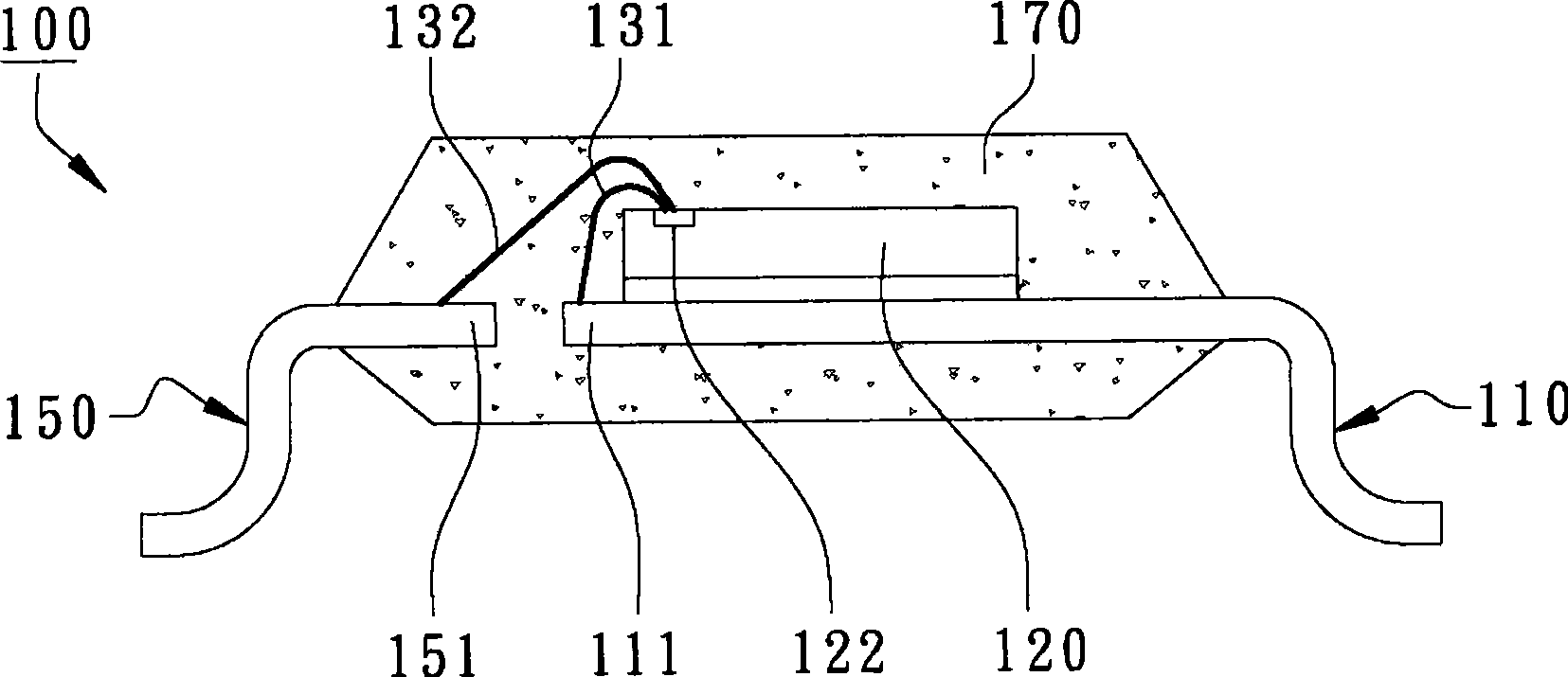

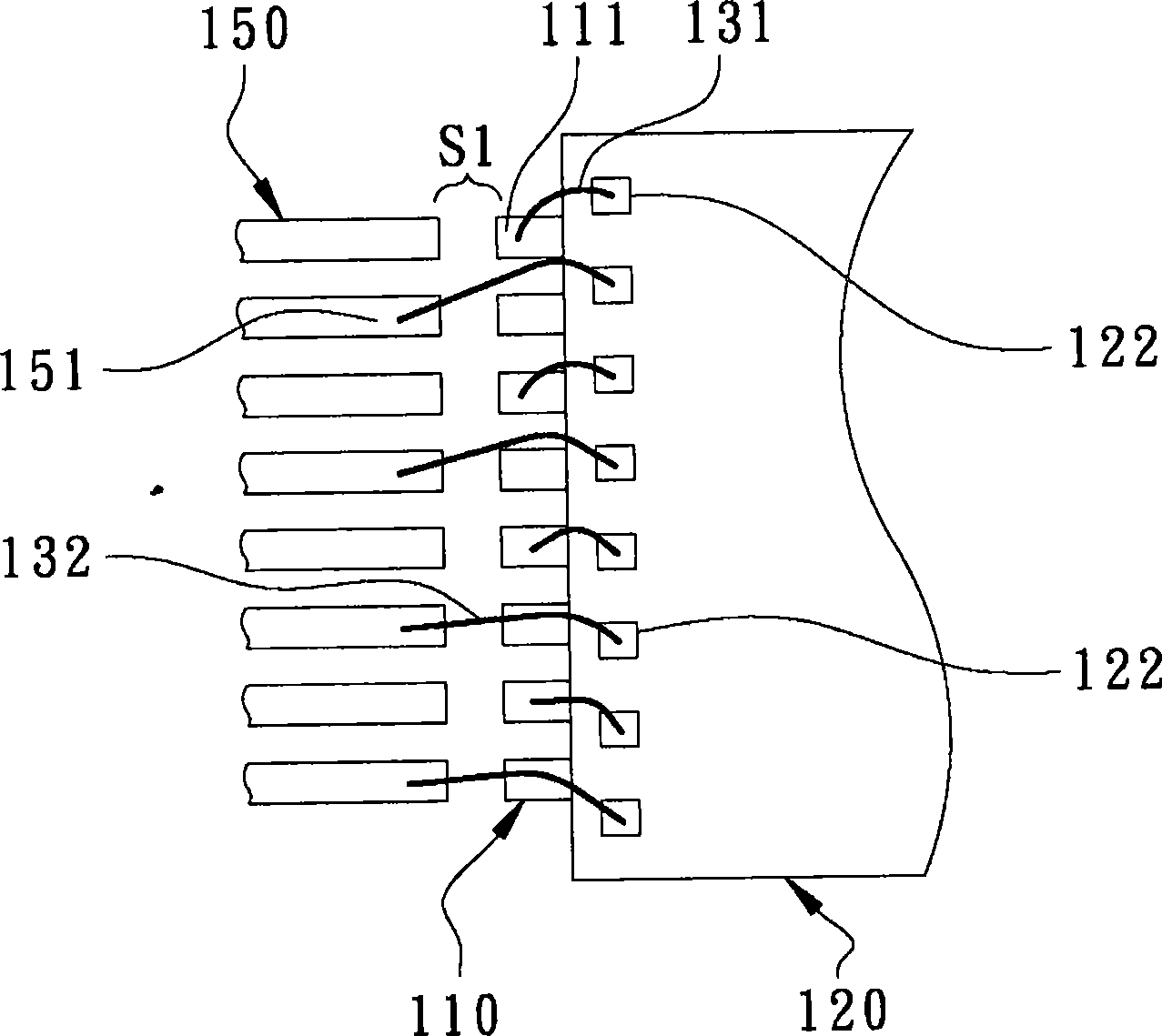

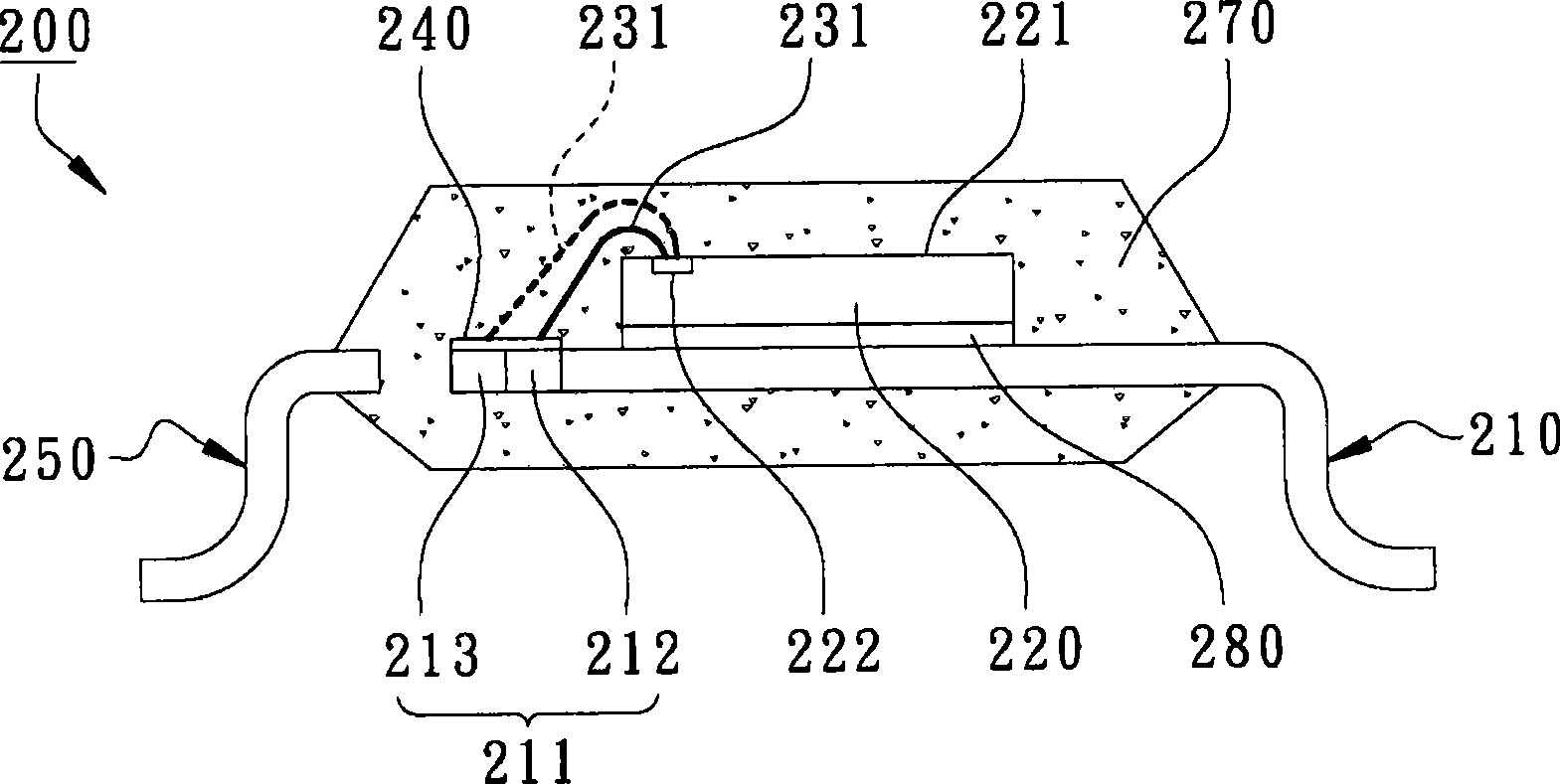

[0072] Figures 3 to 5 It is related to the first specific embodiment of the present invention, which discloses a semiconductor packaging structure in which wires are bonded to multiple fingers. image 3 A schematic cross-sectional view of the first pin is cut for the semiconductor package structure. Figure 4 A schematic cross-sectional view of the second lead is cut for the semiconductor package configuration. Figure 5 is a schematic plan view of the lead frame used in the semiconductor package structu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com