Layout structure of circuit board

A layout structure, circuit board technology, applied in multi-layer circuit manufacturing, printed circuit components, etc., can solve the problem of increasing the equivalent impedance of transmission lines, the distance between transmission line segments cannot be increased, and the line thickness, line width and line spacing of transmission lines cannot be reduced And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In the following two embodiments, the same reference numerals represent the same or similar components.

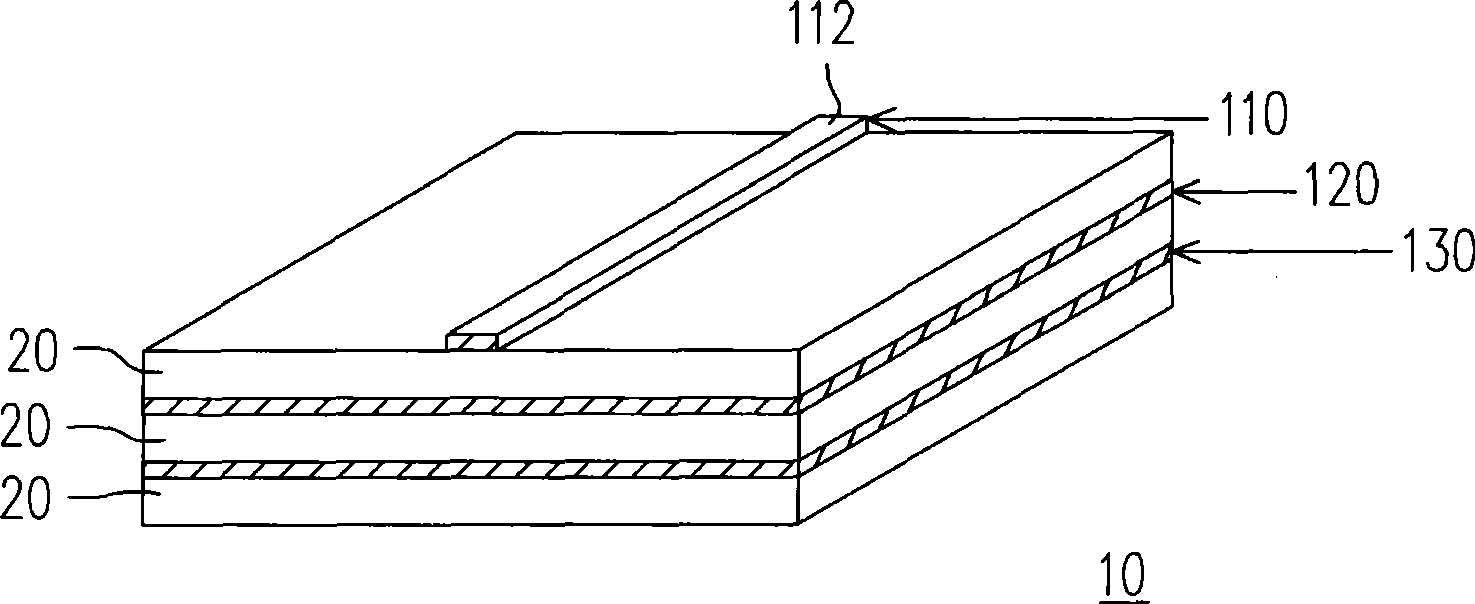

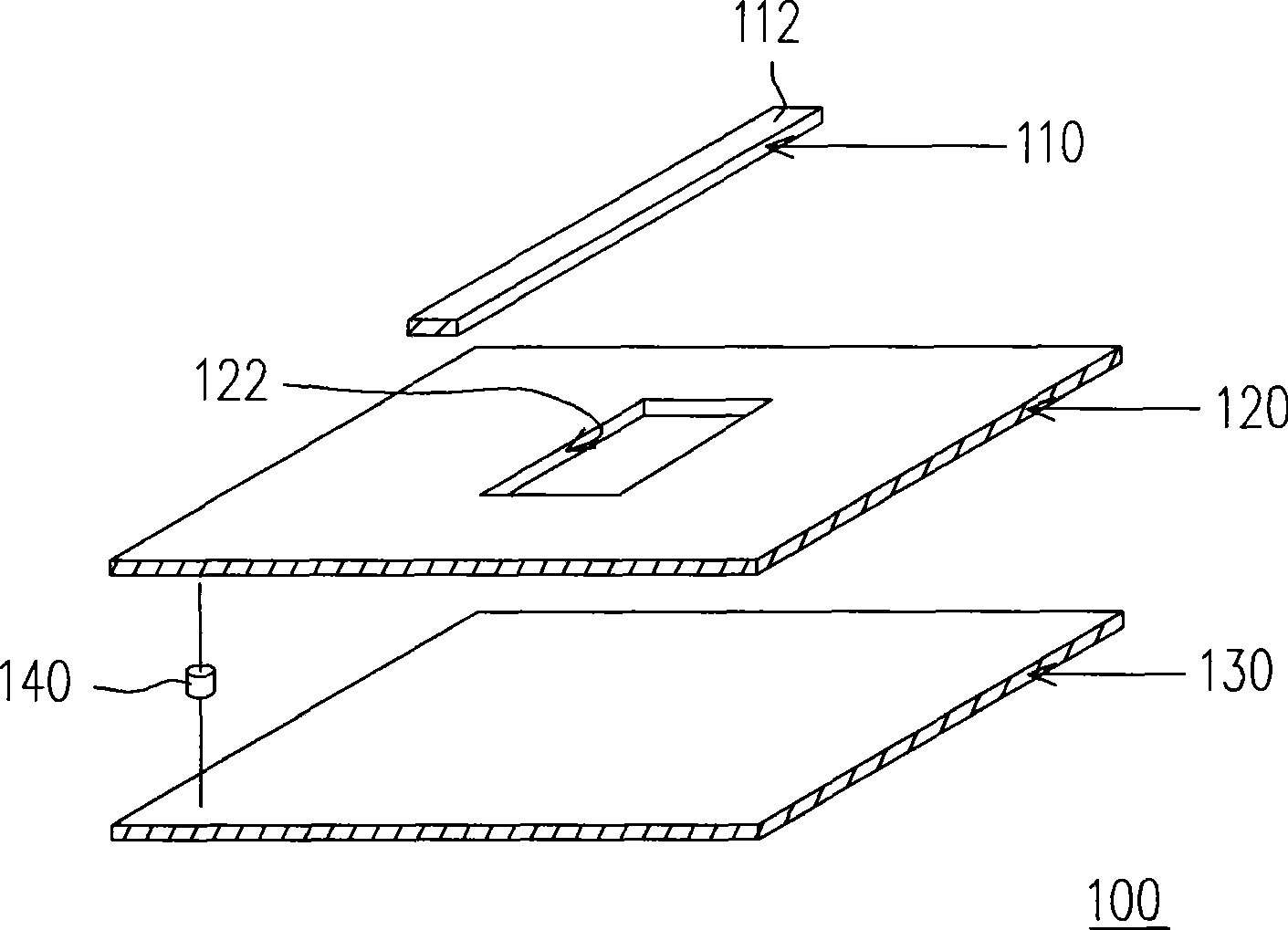

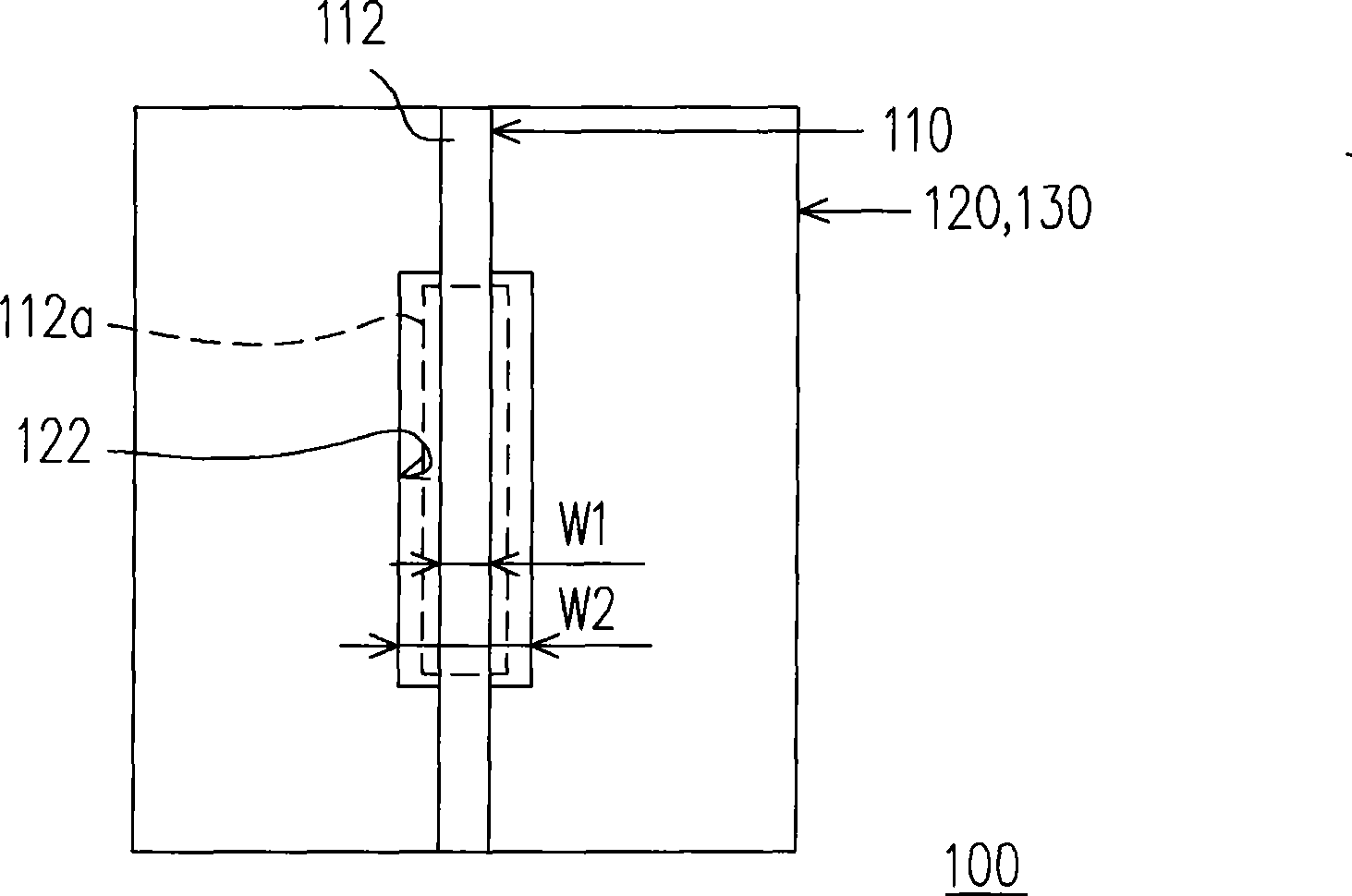

[0034] Figure 1A A circuit board layout structure illustrating an embodiment of the present invention is applied to a circuit board, Figure 1B draw Figure 1A An exploded view of the layout structure, Figure 1C draw Figure 1B A top view of the layout structure. Please refer to Figure 1A to Figure 1C , the circuit board 10 of this embodiment has a layout structure 100, which includes a first signal layer 110, a second signal layer 120 and a third signal layer 130, which overlap in sequence, and the second signal layer 120 is located at the first Between the first signal layer 110 and the third signal layer 130 . In addition, the circuit board 10 also includes a multi-layer dielectric layer 20, which is respectively located between these signal layers 110, 120 and 130 to electrically isolate these signal layers 110, 120 and 130, such as Figure 1A shown.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com