Radiating device

A technology of a heat sink and a heat sink group, which is applied in cooling/ventilation/heating transformation, electrical components, electrical solid devices, etc., can solve the problem of increasing material cost and manufacturing cost, short circuit of circuit board, and loose buckle 122, etc. problems, to reduce assembly and material costs, and eliminate circuit board shorts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

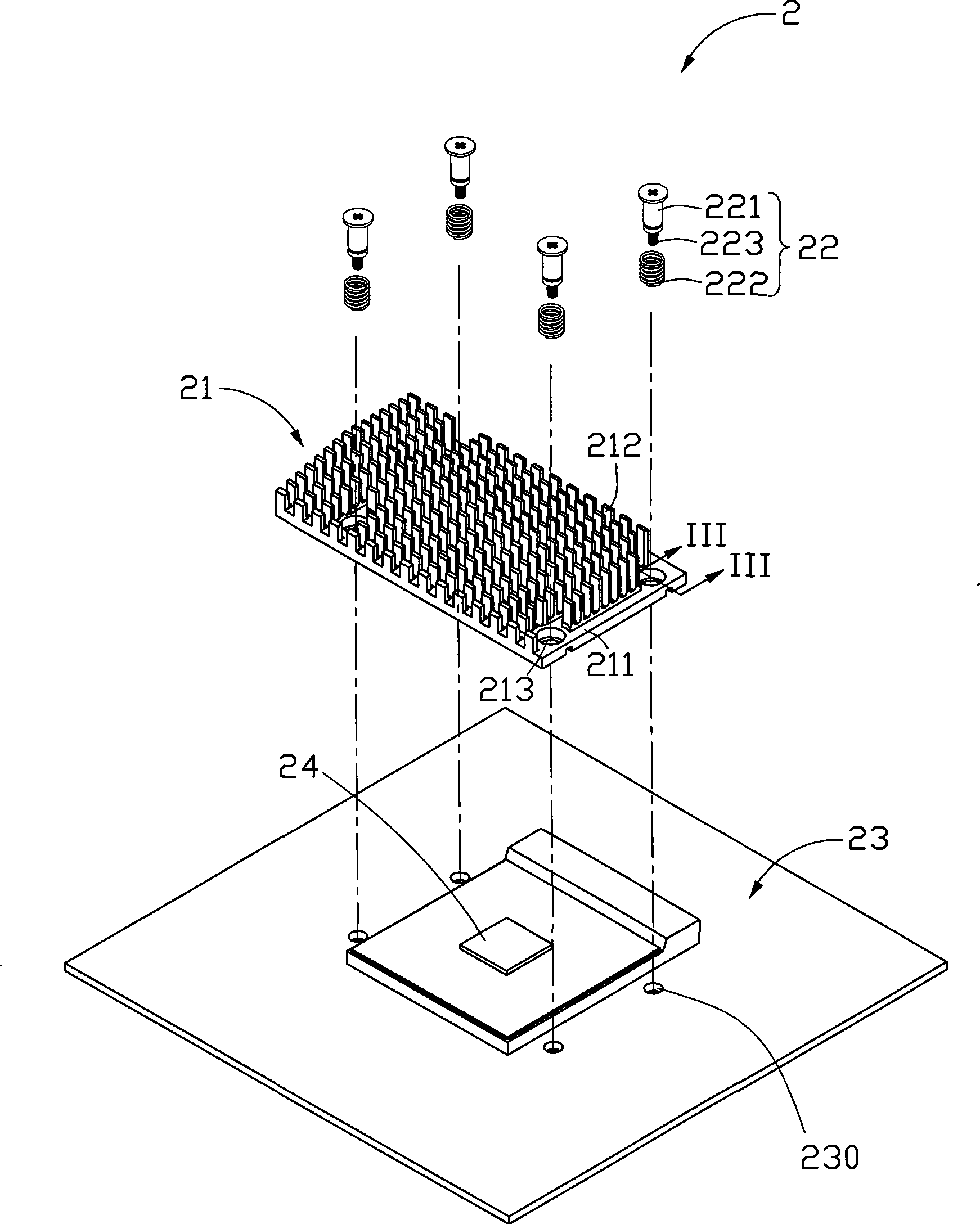

[0014] The heat dissipation device will be further described below with reference to the accompanying drawings. Such as figure 2 , 3 , 4, the cooling device 2 includes a radiator 21, a number of spring fasteners 22, a circuit board 23 and a heating electronic component 24 mounted on the circuit board 23.

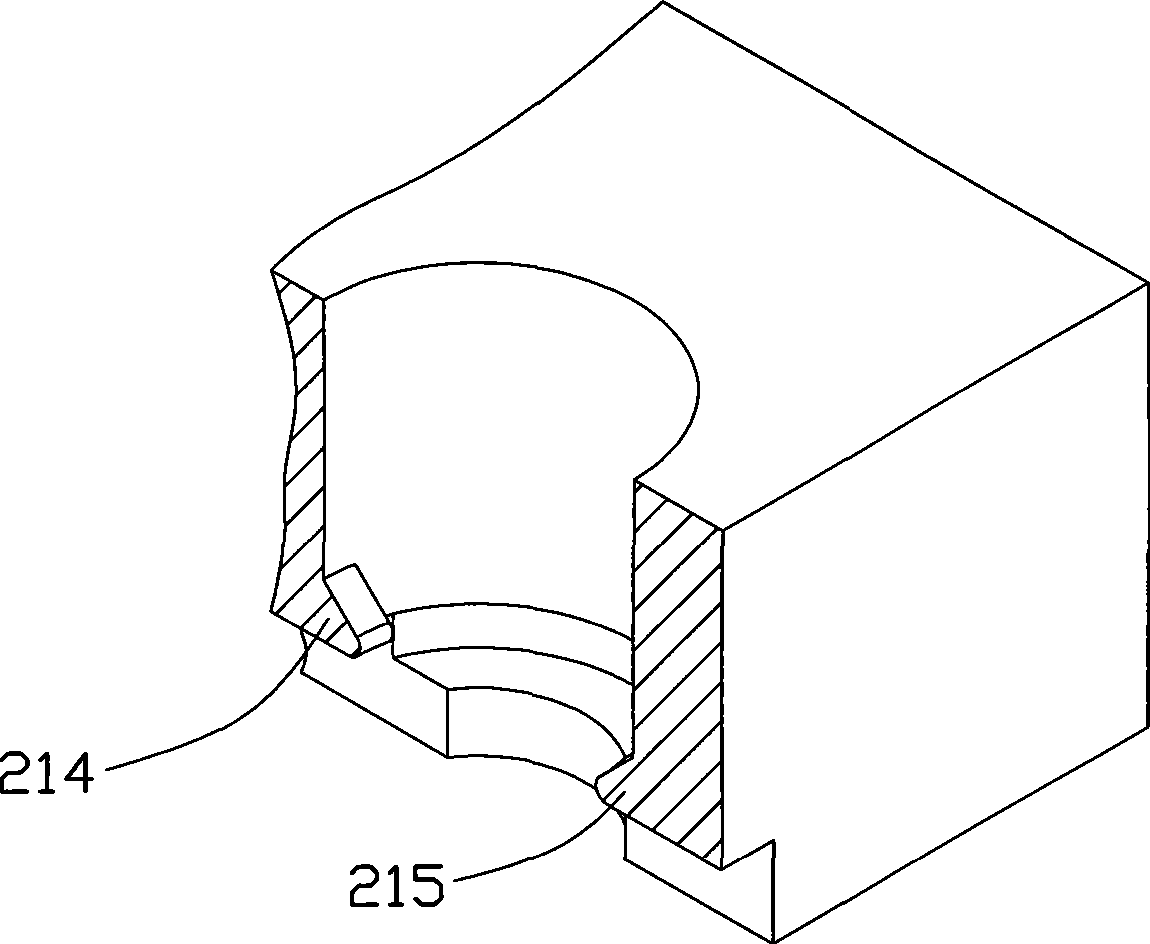

[0015] The spring fastener 22 includes a fastener 221 and a spring 222 . The spring 222 is sheathed on the fastener 221 . In this embodiment, the spring fastener 22 is a spring screw with a thread 223 at its bottom. The fastener 221 forms a threaded connection with the threaded hole 230 on the circuit board 23 . In order to firmly cover the spring 222 on the fastener 221, an annular protrusion 2212 protrudes from the outer surface near the top of the fastener 221, and a groove 2211 is formed between the top of the fastener 221 and the annular protrusion 2212, and the spring 222 The top ring 2221 is set in the groove 2211. When the spring fastener 22 is installed, due to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com