Complex birefringent medium, polarizing plate, and liquid crystal device

A liquid crystal display device, birefringence technology, applied in the directions of optics, polarizing elements, optical elements, etc., to achieve the effect of improving the degree of freedom, easy control, and realizing broadbandization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

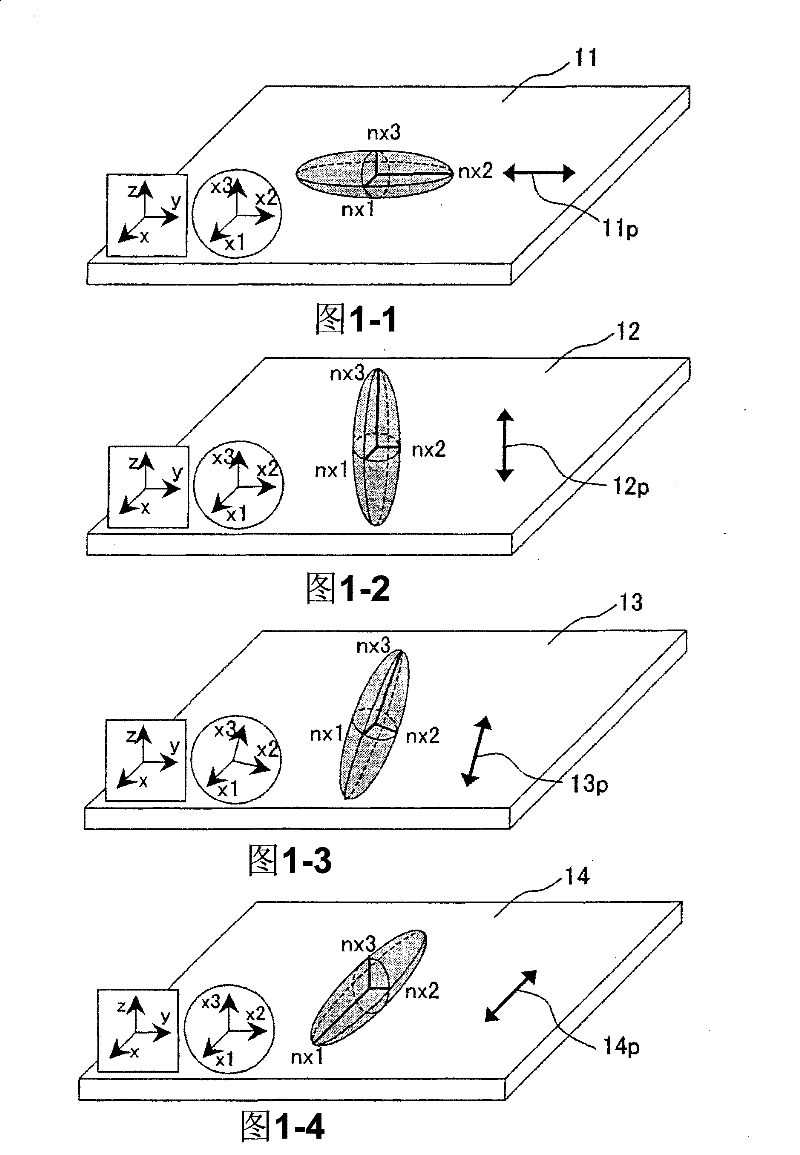

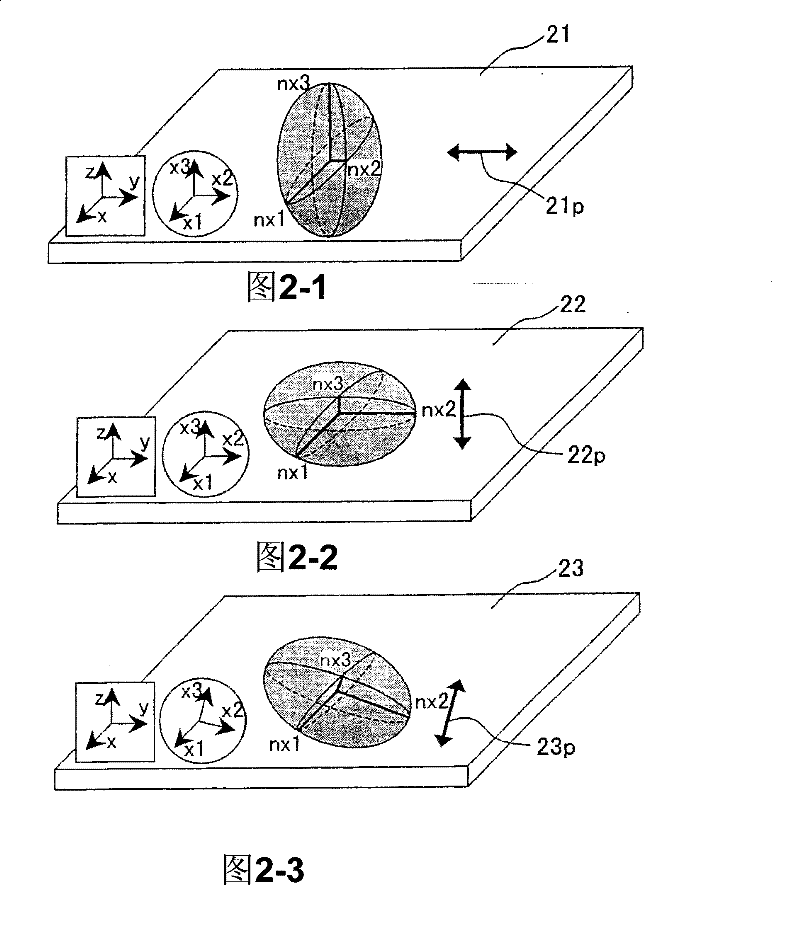

Method used

Image

Examples

Embodiment 1

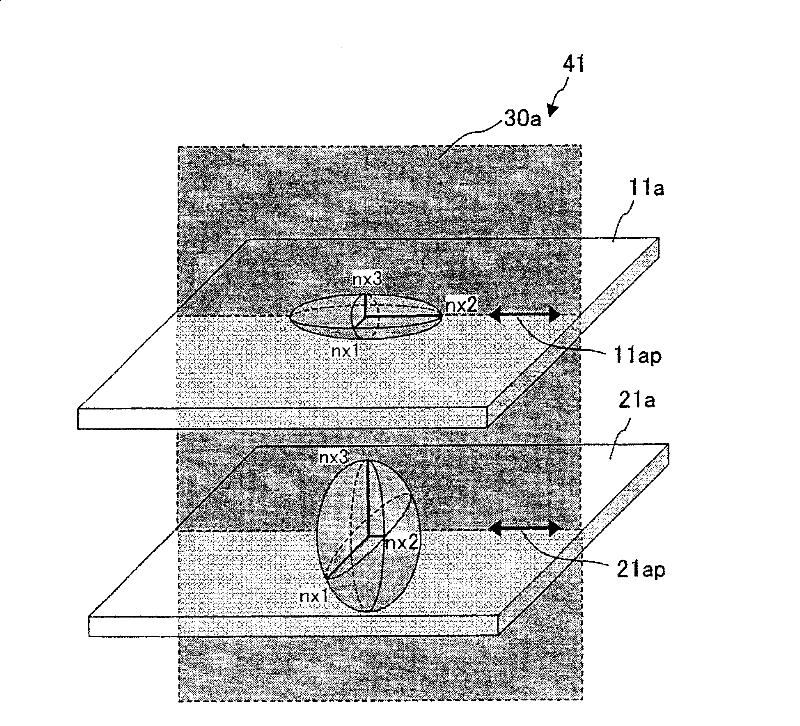

[0283] The first birefringent layer (first birefringent layer) formed by uniaxially stretching a norbornene resin (NB) film and the second birefringent layer (second birefringent layer) formed by uniaxially stretching a polystyrene resin (PS) film Two kinds of birefringent layers) are laminated through a transparent acrylic adhesive without birefringence to form the composite birefringent medium of Example 1.

Embodiment 2

[0285] The first birefringent layer (first birefringent layer) formed by uniaxially stretching a norbornene resin film laterally and the second birefringent layer (second birefringent layer) formed by laterally uniaxially extending a polystyrene resin film layer) was laminated with a transparent acrylic adhesive having no birefringence to form the composite birefringent medium of Example 2.

Embodiment 3

[0287] The first birefringent layer (first birefringent layer) formed by biaxially stretching a norbornene resin film and the second birefringent layer (second birefringent layer) formed by laterally uniaxially stretching a polystyrene resin film ) are laminated with a transparent and non-birefringent acrylic adhesive to form the composite birefringent medium of Example 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com