Optical film having reverse wavelength dispersibility and display device comprising same

A technology of optical film and chemical formula, applied in the field of optical film, can solve the problems of loss of liquid crystal characteristics, inability to induce reverse wavelength dispersion, etc., and achieve the effect of thin thickness and excellent reverse wavelength dispersion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

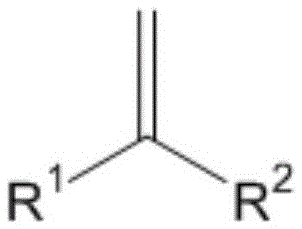

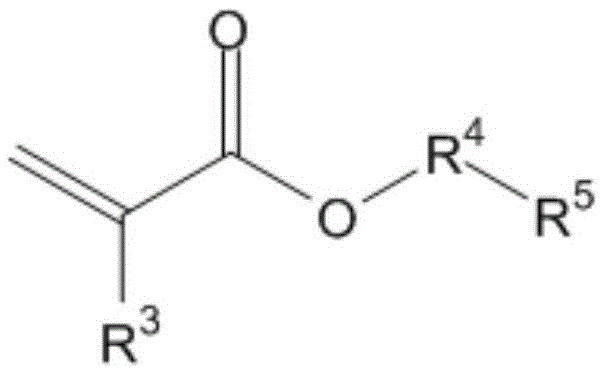

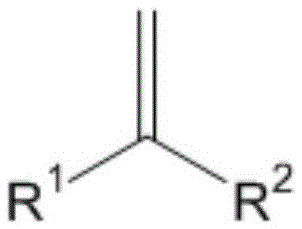

Method used

Image

Examples

preparation example Construction

[0085] In the preparation method of another embodiment of the present invention, the step of preparing the copolymer can be carried out by the following process: at a temperature of 20 to 120° C., while stirring, polymerizing the compound containing 80-99.99% by weight of the chemical formula 1 The compound and the monomer mixture of 0.01-20% by weight of the acrylate-based compound, the organic solvent and the polymerization initiator are combined for 1 to 24 hours.

[0086] Here, organic solvents and polymerization initiators commonly used in the art to which the present invention pertains may be used in the polymerization reaction, and their types are not particularly limited.

[0087] According to one embodiment of the present invention, the organic solvent may include: aromatic hydrocarbons, such as toluene, xylene, etc.; esters, such as ethyl acetate, butyl acetate, ethylene glycol monomethyl ether acetate, ethylene glycol Monoethyl ether acetate, propylene glycol monome...

Embodiment 1

[0098] A monomer mixture comprising about 90% by weight of N-vinylcarbazole and about 10% by weight of acrylic acid, about 200 parts by weight of solvent toluene based on 100 parts by weight of the monomer mixture, and 0.05 parts by weight of a polymerization initiator Azobisisobutyronitrile was added to the reactor, and then at about 70° C., polymerization was carried out for 18 h while stirring, to obtain a compound containing a copolymer (having a weight average molecular weight of about 120,000 and a glass transition temperature of about 197° C.). solution.

[0099] The solution was cast on a cycloolefin polymer film (having a thickness of about 100 μm), then dried, and stretched (about twice) in the longitudinal direction to obtain an optical film having a thickness of about 67 μm (including the substrate).

[0100] Measure the retardation value of the optical film, the result is Δn (450nm) =0.88, Δn (550nm) = 1.00 and Δn (650nm) =1.07, confirming that the optical film...

Embodiment 2

[0102]In the same manner as in Example 1, except for using a monomer mixture containing about 95% by weight of N-vinylcarbazole and about 5% by weight of acrylic acid, a copolymer (having a weight average molecular weight of about 130,000 and about 202 °C glass transition temperature) solution. An optical film having a thickness of about 65 μm was obtained by performing solution casting and stretching processes in the same manner as in Example 1 except for using the above solution.

[0103] Measure the retardation value of the optical film, the result is Δn (450nm) =0.88, Δn (550nm) = 1.00 and Δn (650nm) =1.06, confirming that the optical film satisfies the conditions according to Formula I and Formula II.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com