Fine filtering process and device for dry-cleaning solvent

A dry cleaning solvent and fine filtration technology, applied in washing devices, loose filter material filters, dry cleaning equipment, etc., can solve the problems of reduced permeability of filter paper, inability to use normally, complicated purification structure, etc. Reduced contact opportunities, small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

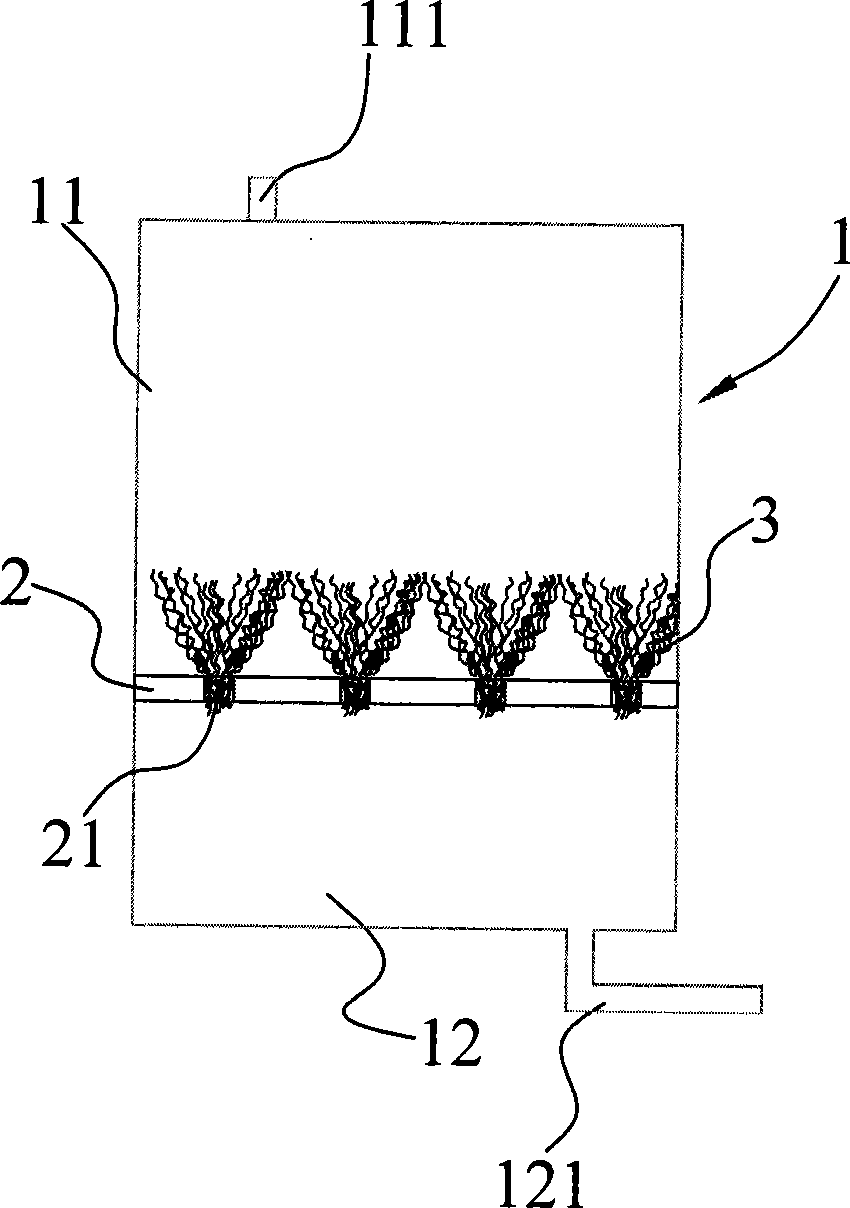

[0023] Embodiment 1: present embodiment also provides the special dry-cleaning solvent fine filter device that adopts above-mentioned method, and this device has special effect for the pre-distillation filtration of the perchlorethylene solvent used in dry-cleaning, figure 1 It is a schematic structural view of the dry cleaning solvent fine filter device of the present invention, as figure 1 As shown, the dry-cleaning solvent fine device of the present invention comprises a casing 1, is provided with a dividing plate 2 in the casing, and this dividing plate divides the casing into the solvent box 11 to be filtered and the solvent box 12 to be cleaned, the solvent box 11 to be filtered The upper part is provided with a liquid inlet 111, the lower part of the cleaning solvent tank 12 is provided with a liquid outlet 121, and a hole 21 is provided on the partition plate 2, and a fiber bundle 3 composed of fiber filaments is inserted in the hole 21, and one end of the fiber bundle ...

Embodiment 2

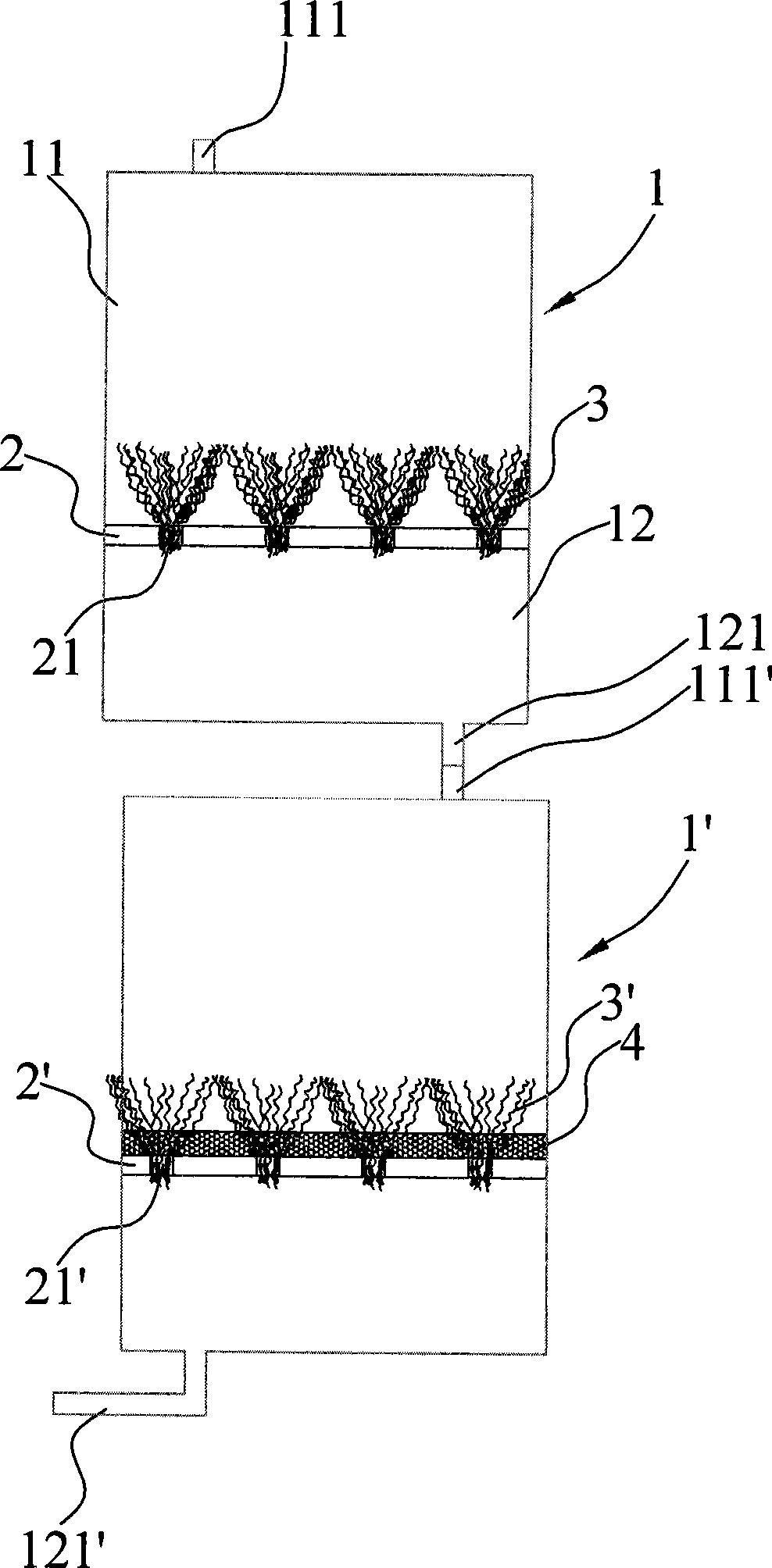

[0025] Embodiment 2: This embodiment provides a kind of technical scheme aiming at using petroleum solvent in the dry cleaning industry, figure 2 It is a schematic structural view of the dry cleaning solvent fine filter device of the present invention, as figure 2 As shown, the dry-cleaning solvent fine device of the present invention comprises a casing 1, is provided with a dividing plate 2 in the casing, and this dividing plate divides the casing into the solvent box 11 to be filtered and the solvent box 12 to be cleaned, the solvent box 11 to be filtered The upper part is provided with a liquid inlet 111, the lower part of the cleaning solvent tank 12 is provided with a liquid outlet 121, and a hole 21 is provided on the partition plate 2, and a fiber bundle 3 composed of fiber filaments is inserted in the hole 21, and one end of the fiber bundle 3 passes through The partition hole 21 extends to the cleaning solvent tank 12 .

[0026] The lower liquid outlet 121 communic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com