Module assembling type rolling writing board

An assembled, writing board technology, applied in the field of writing demonstration equipment, can solve the problems of inability to form a large writing surface, unsuitable for transportation and circulation, limited application scope, etc., to achieve easy maintenance and maintenance, avoid air pollution, easy to package protection Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

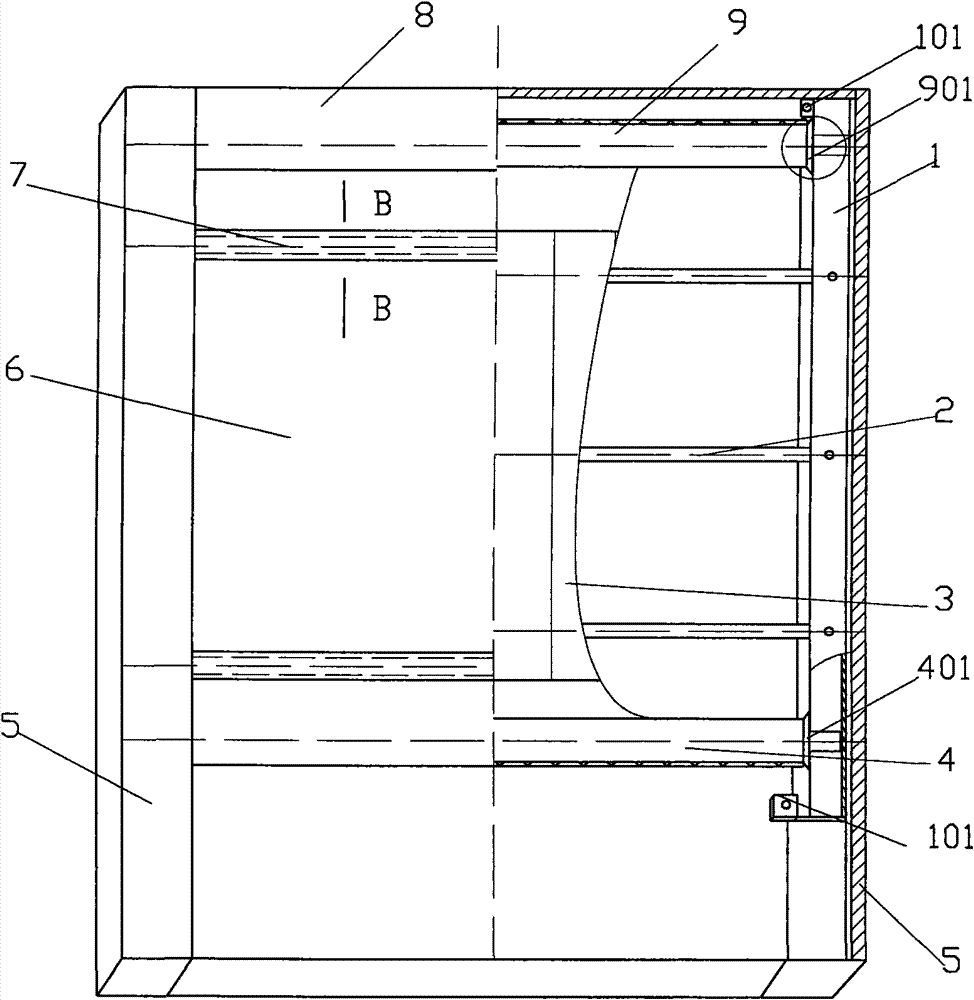

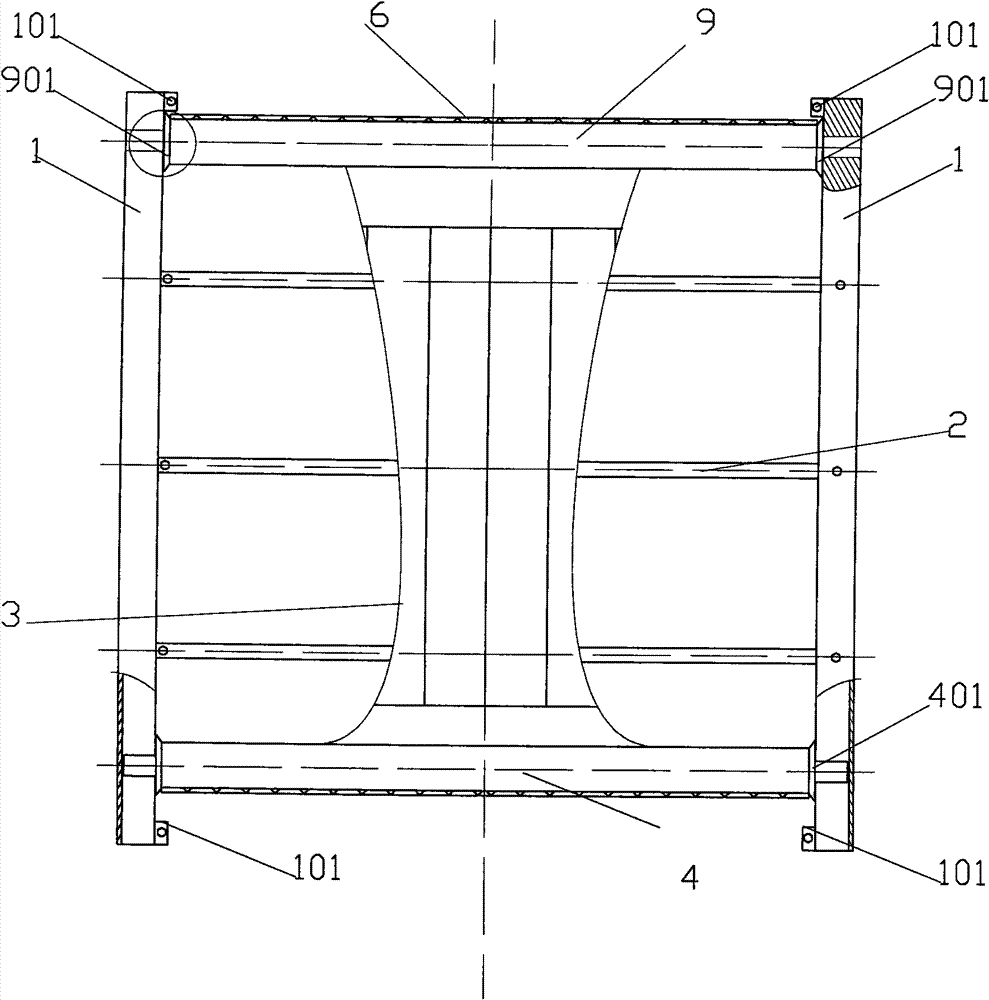

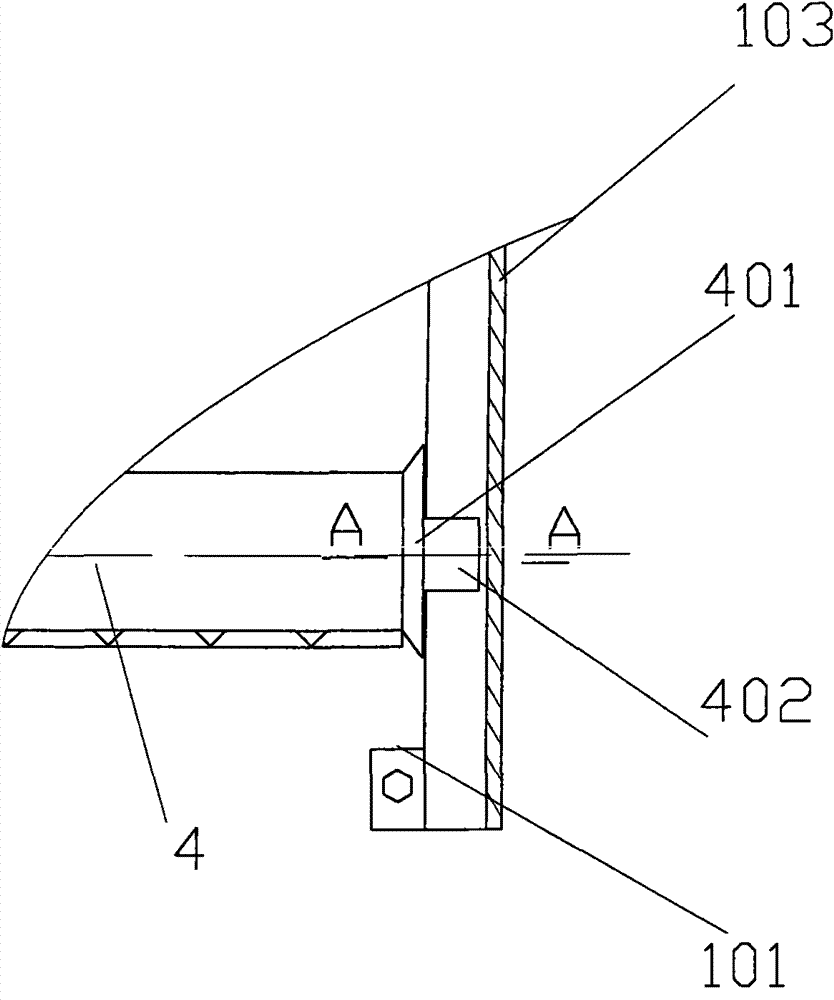

[0037] A manual wall-mounted modular assembled rolling type writing board, such as figure 1 , 11As shown, it adopts a modular assembly structure. It includes: a main body frame 1, a flexible board surface 6 of a rolling writing board, which is wrapped in a ring shape outside the upper rotating shaft 9 and the lower rotating shaft 4, the described main body frame 1 is a left and right column, and the upper rotating shaft 9 and the main body frame 1 is hinged, the lower rotating shaft 4 is rollingly matched with the main body frame 1 through the connecting pair 103; the flexible board surface 6 of the scrolling writing board is connected by the first and last ends of four flexible board surfaces 601 of different materials through the connecting device 7 As a result, the four flexible boards 601 can be made of different materials, so as to be suitable for different demonstration tools. For example: chalk, whiteboard markers, projection, etc. A hard base plate is arranged betwe...

Embodiment 2

[0052] A mobile scrolling tablet such as Figure 12 As shown, its structure is basically the same as that of Embodiment 1, and the difference is that wheels are provided at the bottom of the main body frame 1 . This way it can be moved easily.

Embodiment 3

[0054] An electric modular assembled rolling type writing board, such as Figure 13 As shown, its structure is basically the same as that of Embodiment 1, the difference is that: the shaft end of the upper rotating shaft 9 or the lower rotating shaft 4 is connected with a power transmission device driven by a motor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com