Complete fibre vehicle foot pad and method for producing the same

A car floor mat and full-fiber technology, which is applied to vehicle parts, special positions of vehicles, transportation and packaging, etc., can solve problems such as insufficient adhesion, insufficient braking by the driver, and easy falling of coke particles, etc., to achieve Ensure normal and safe operation, ensure the firmness of the combination, and have good anti-skid effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

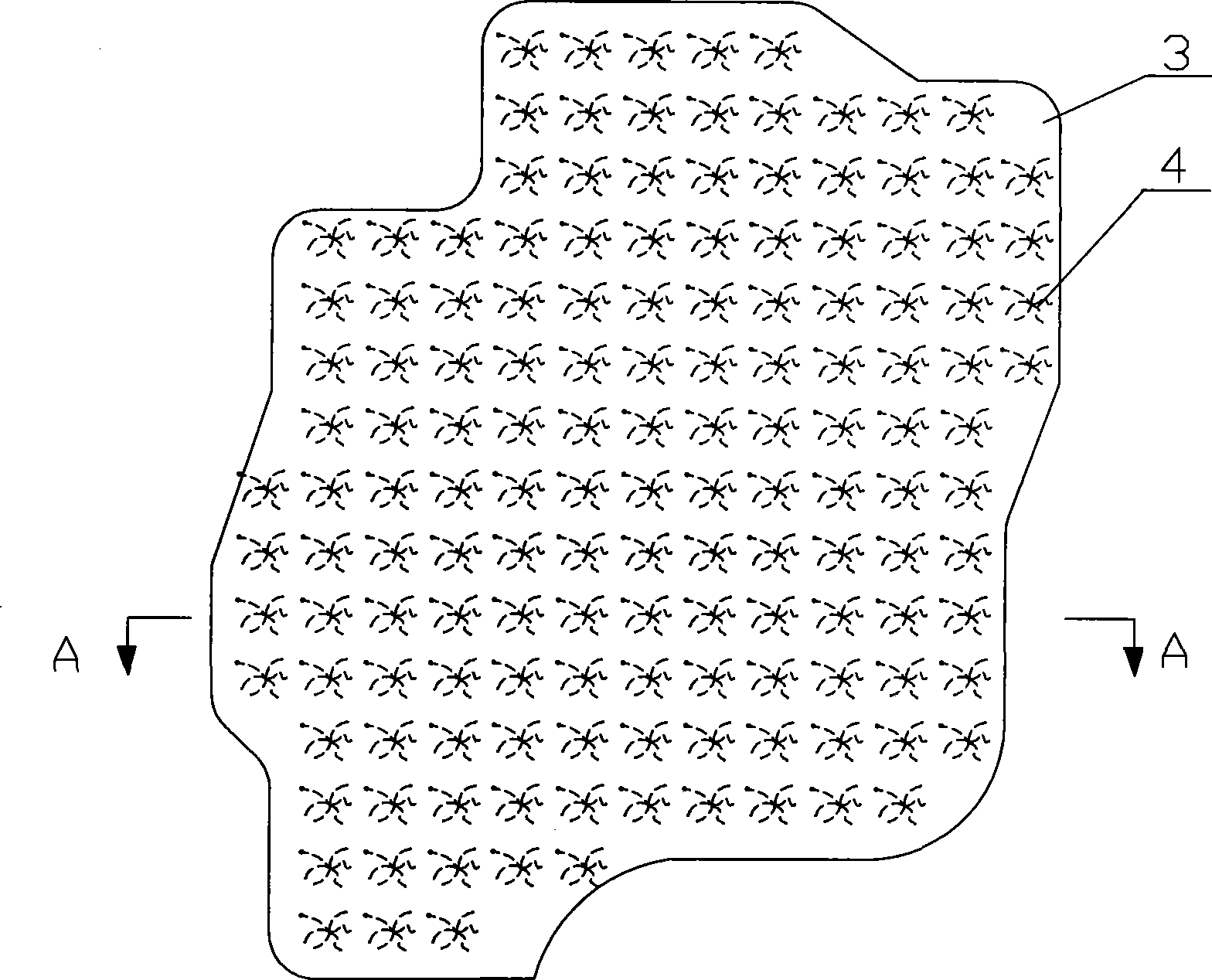

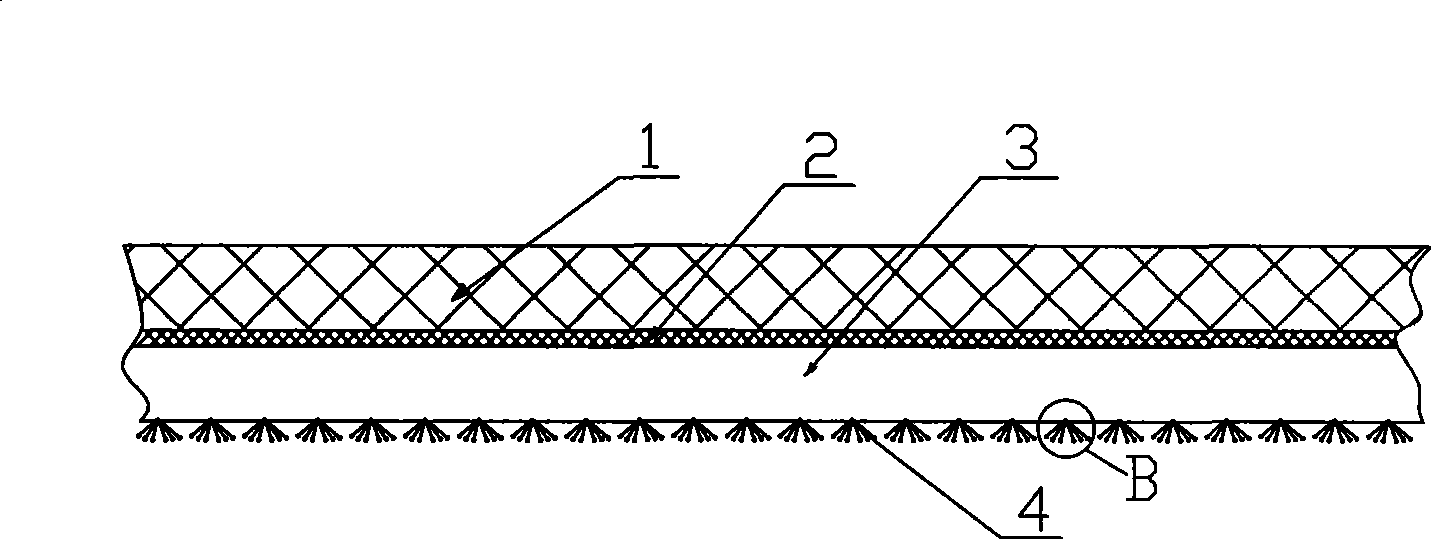

[0024] Such as figure 1 , figure 2 As shown, the full-fiber car floor mat of the present invention comprises a carpet body 1, and the bottom surface of the carpet body 1 is provided with a bottom layer 3 made of a needle-punched carpet body, and a heating layer is arranged between the bottom layer 3 and the carpet body 1. The melt adhesive layer 2 is characterized in that: the bottom surface of the bottom layer 3 is also provided with a woven plastic yarn tuft 4, the material of the plastic yarn tuft 4 can be selected as PET or PA, and the plastic yarn tuft 4 is The number and length of the plastic wires can be adjusted according to the adhesion required by the car floor mat.

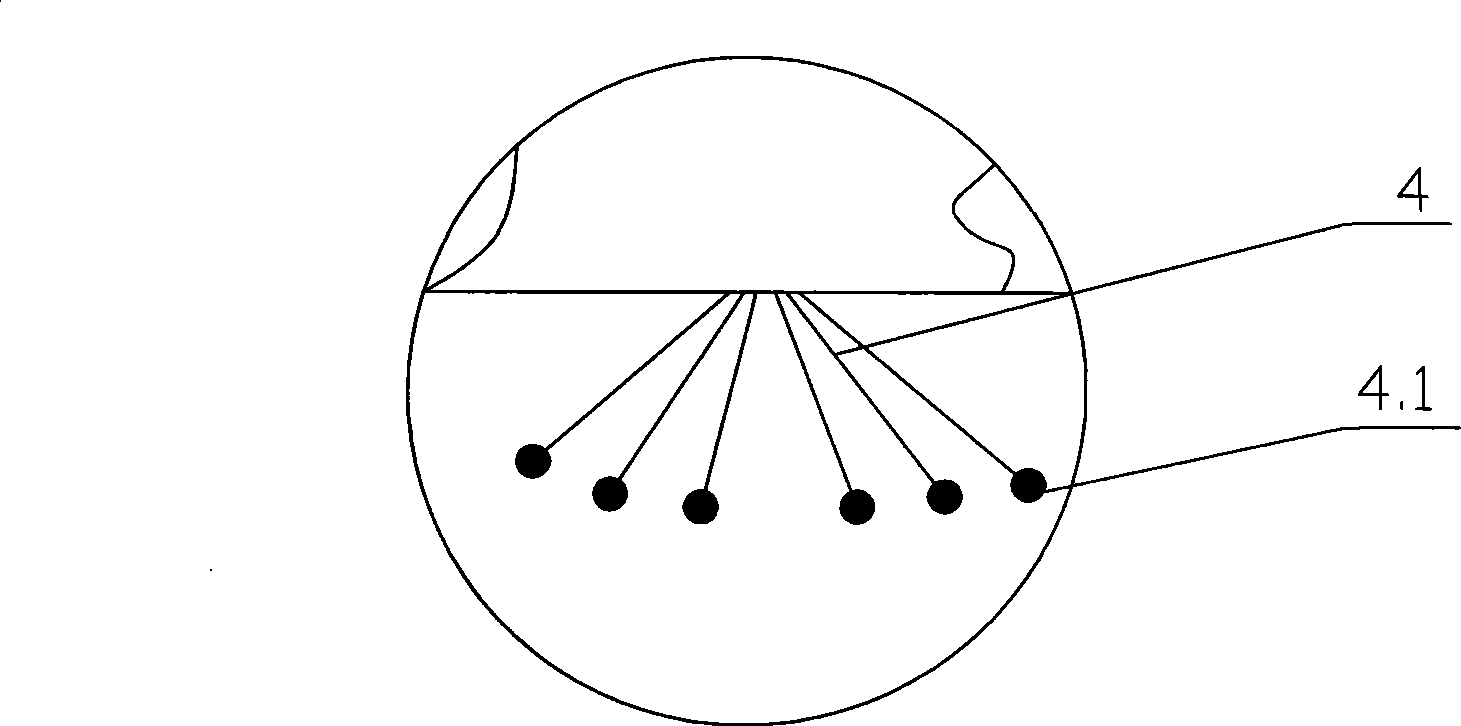

[0025] Such as image 3 As shown, the ends of the plastic filaments of the plastic filament tuft 4 are blanched protrusions 4.1.

[0026] The plastic filament clust...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com