Stop gear positioning structure of anti-counterfeit winebottle cap

A technology of limiting structure and wine bottle cap, applied in the directions of bottle/container cap, capping, bottle filling, etc., which can solve the problems of easy generation of plastic waste, loss of anti-counterfeiting effect, breakage or falling off, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

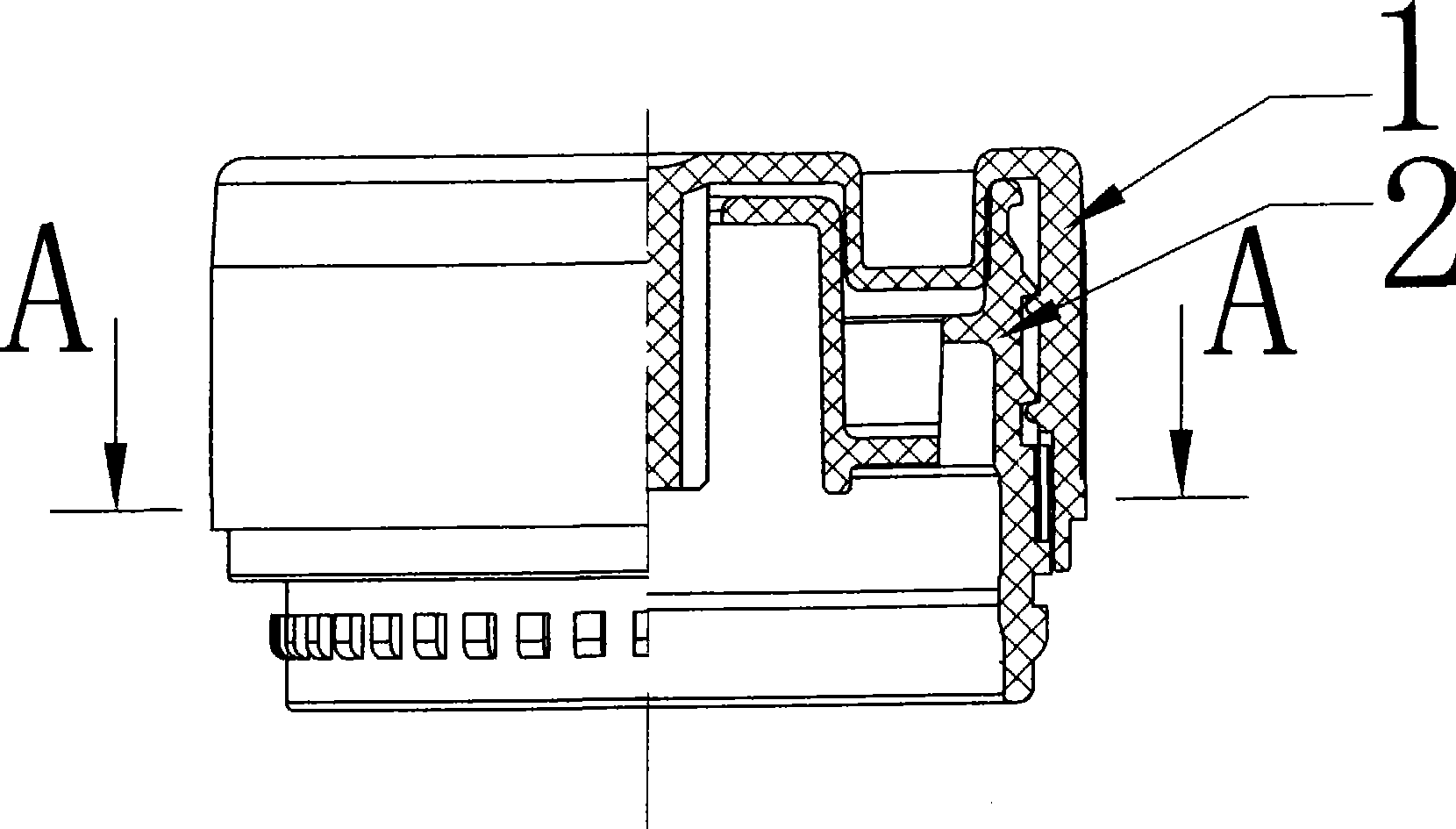

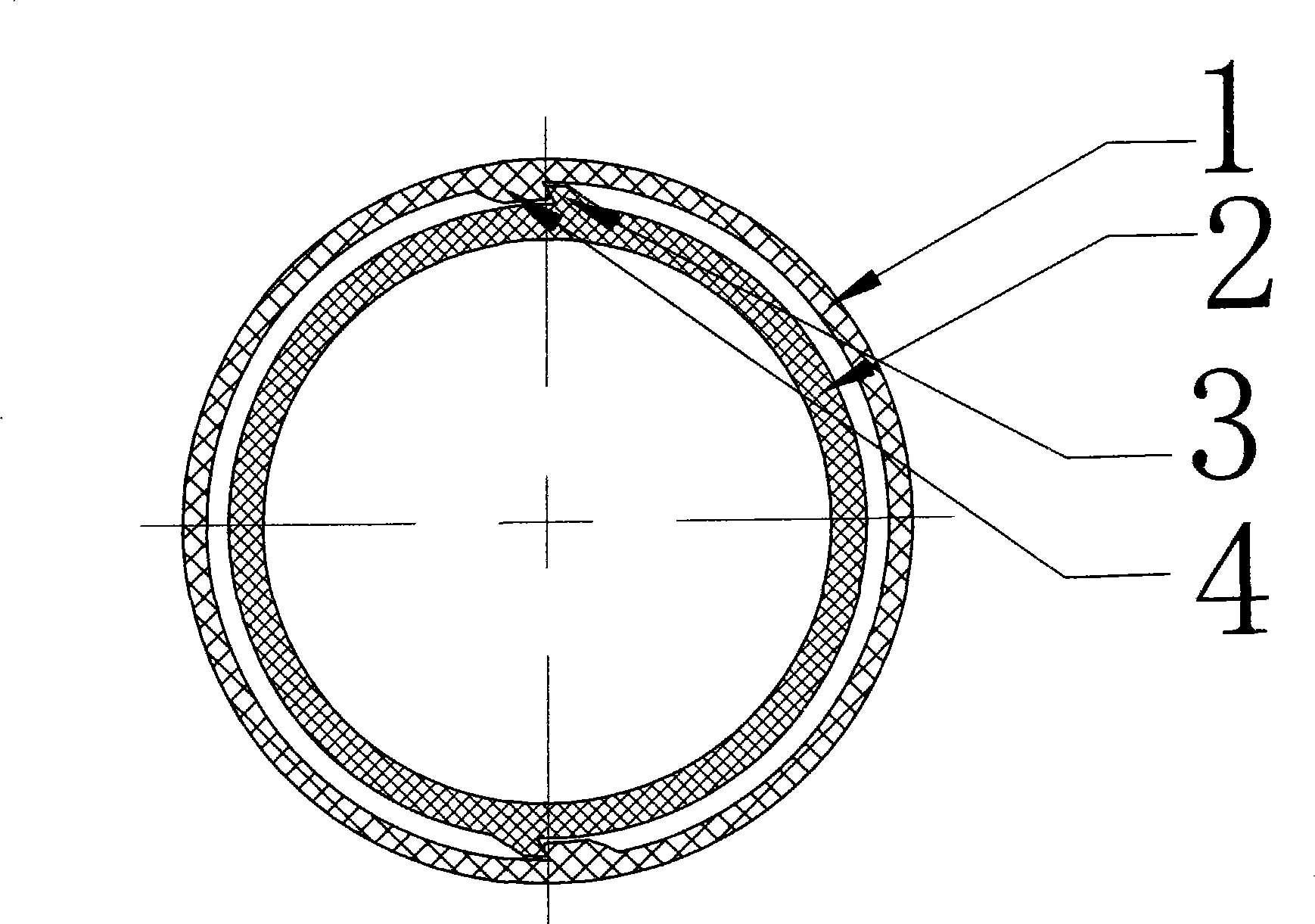

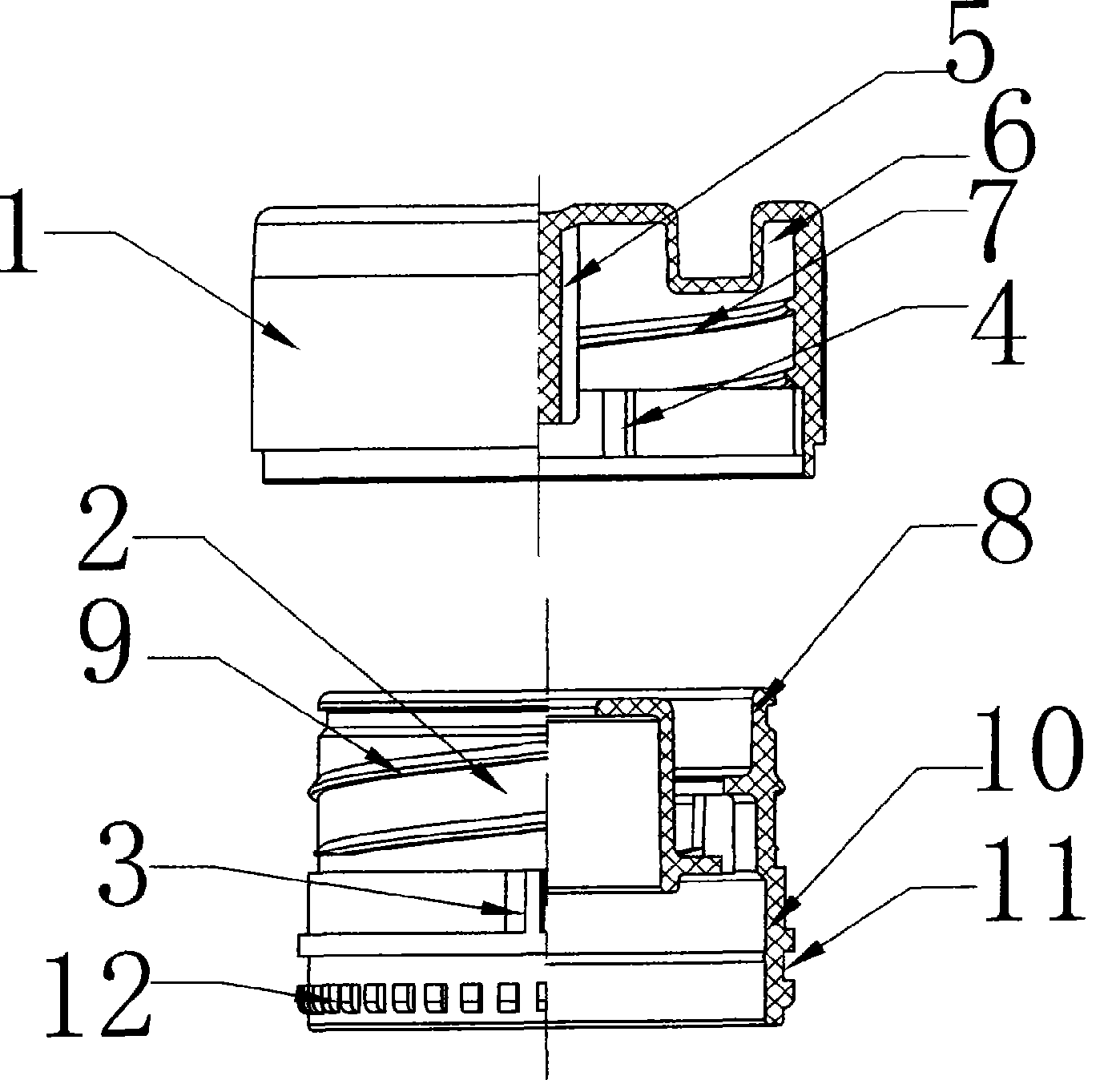

[0018] The present invention mainly consists of an upper cover 1 with internal threads 7, internal resistance teeth 4, outer sealing rings 6, and cross ribs 5, externally equipped with external threads 9, external resistance teeth 3, internal sealing rings 8, 10, and a positioning concave ring 11. , The connecting cover 2 of the outer stop gear 12 etc. constitutes.

[0019] Taking the installation of the present invention on an aluminum-plastic six-piece set as an example, the assembly steps are divided into the following four points:

[0020] 1 Put the lower sleeve on the workbench, press the connecting cover 2 vertically from top to bottom into the lower sleeve, because the positioning concave ring 11 on the connecting cover 2 matches the positioning convex ring in the lower sleeve, the connecting cover will not Can be pulled out; The outer anti-rotation tooth 12 on the connection cover 2 matches the inner anti-rotation tooth in the lower cover, and the connection cover 2 wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com