Method for steel product batch hot dip galvanizing

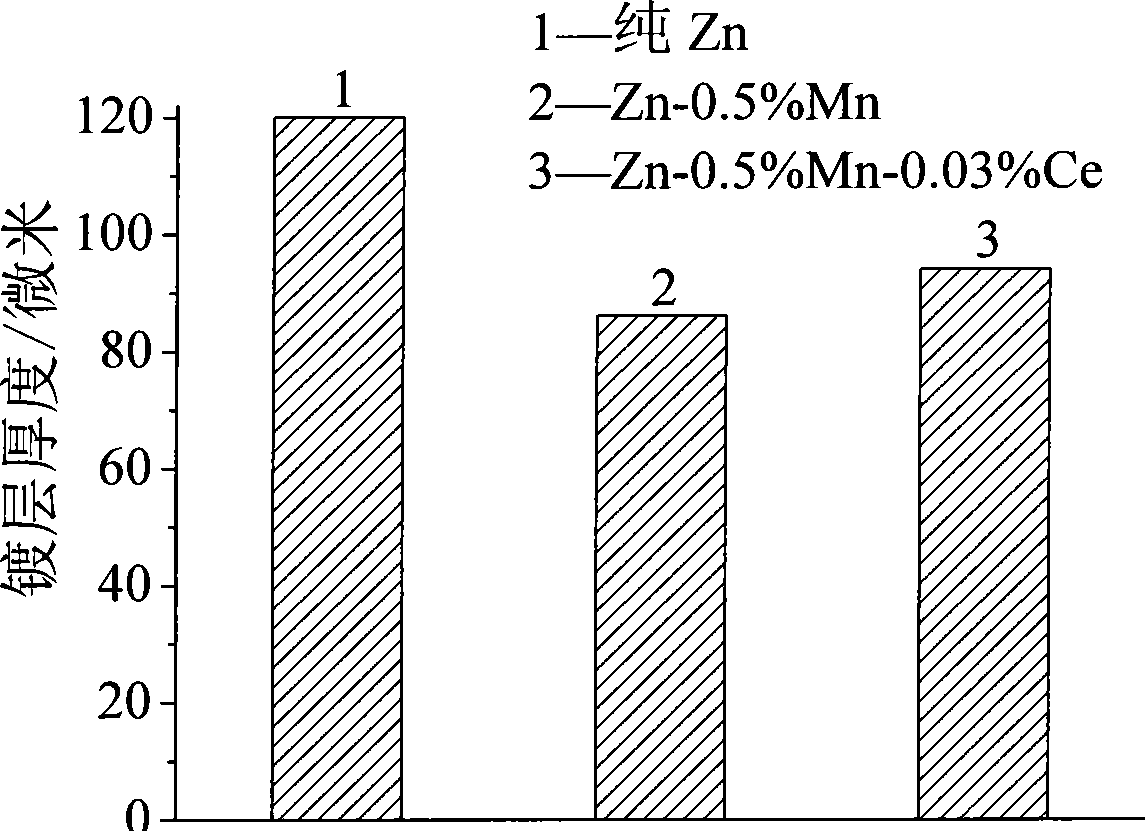

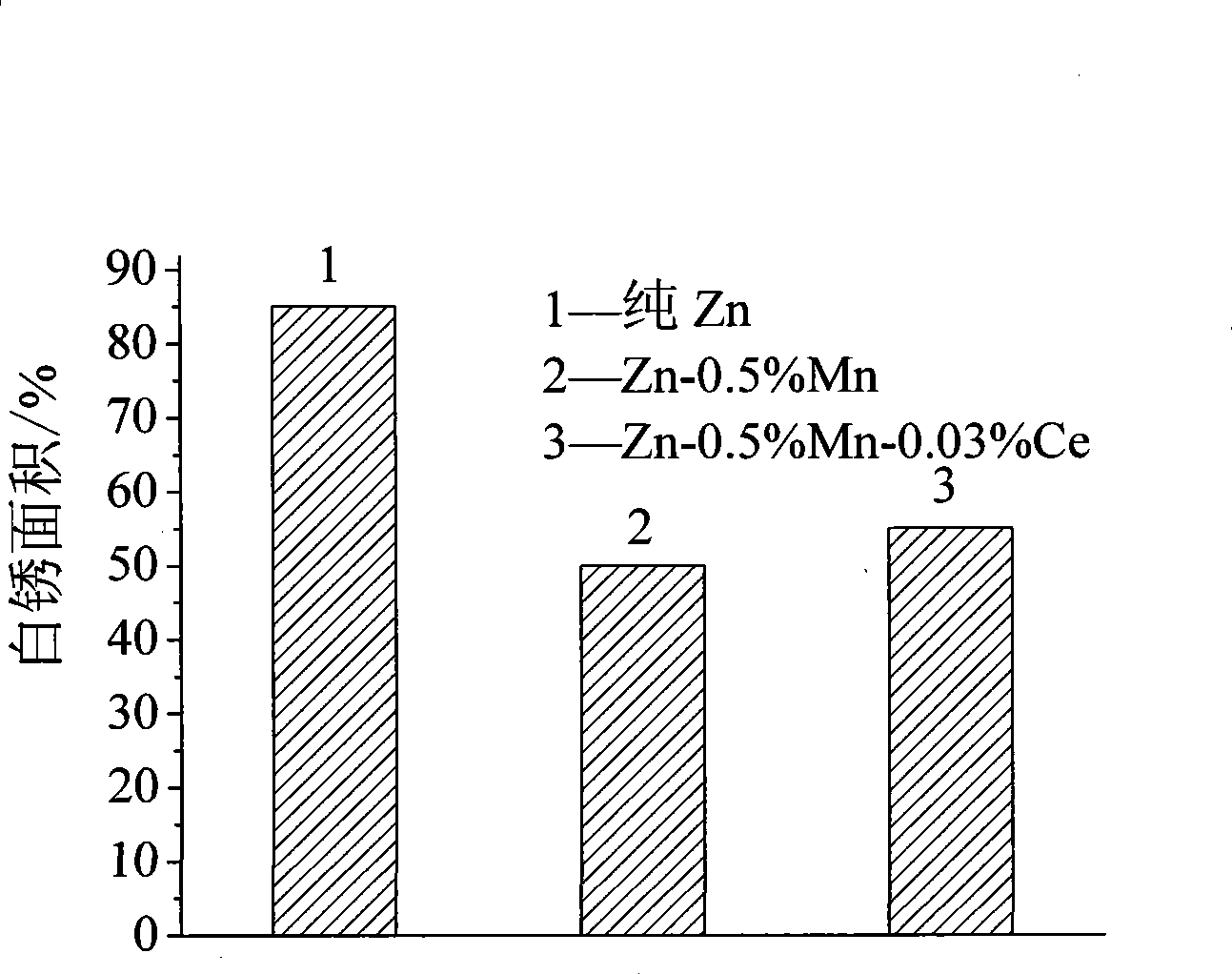

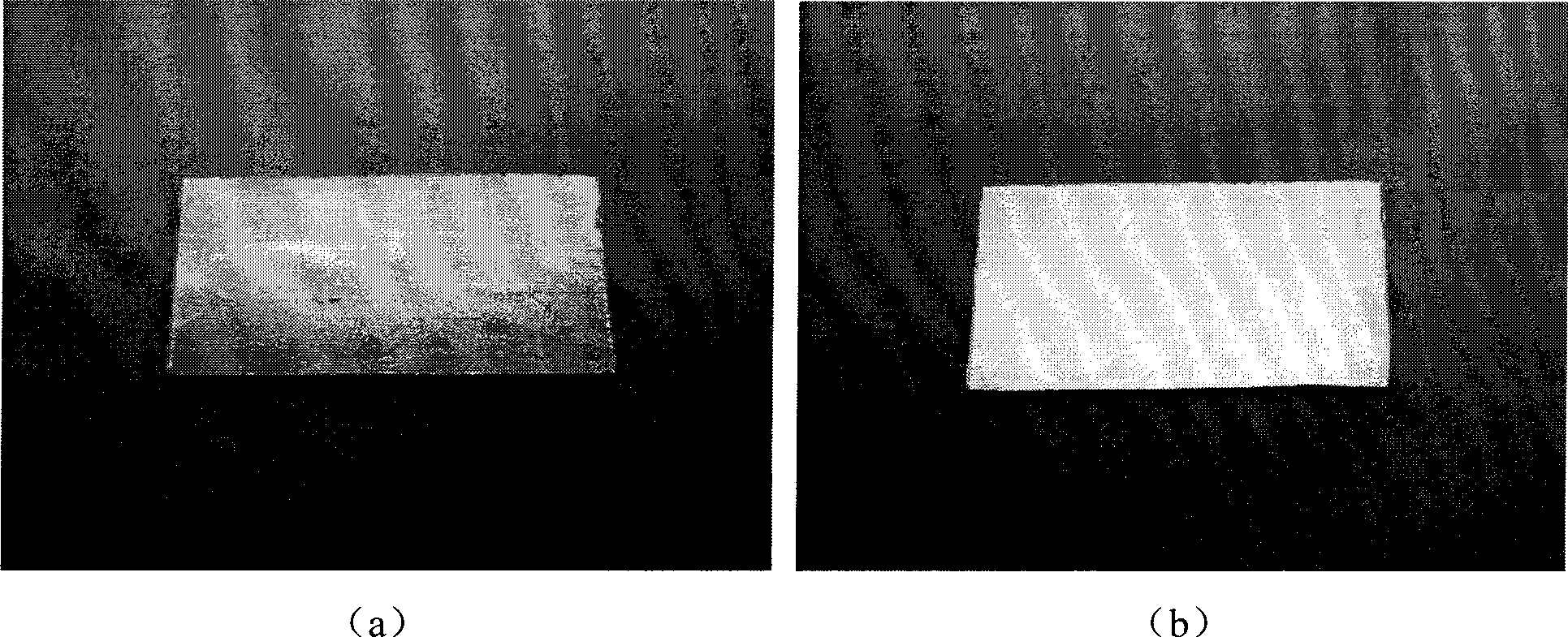

A hot-dip galvanizing and steel technology, applied in hot-dip plating process, metal material coating process, coating and other directions, can solve the problem of inability to suppress the ultra-thick growth of silicon-containing active steel coating, the promotion and application of zinc-manganese alloy coating, Improve the production cost of zinc-nickel master alloys, and achieve the effects of inhibiting super-thick growth, delaying the formation of white rust, and eliminating cluttered and uneven colors.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The steel used for galvanizing is a steel plate containing 0.10% Si, and the chemical composition is shown in Table 1 below. The hot-dip galvanizing method includes the following steps and process conditions:

[0022] (1) Binary master alloy refining: Weigh manganese and zinc, cerium and zinc in proportion by weight, place them in graphite crucibles, and refine them respectively. Among them: the manganese weight content in zinc-manganese binary master alloy is 3%, the melting temperature of zinc-manganese master alloy is 800 ℃, and the holding time is 3 hours; the cerium weight content in zinc-cerium binary master alloy is 2.6%, zinc cerium The melting temperature of the master alloy is 770°C, and the holding time is 2.5 hours. After each intermediate alloy liquid is kept warm, it is stirred, left still and the ash on the surface of the alloy liquid is removed, and then poured into an intermediate alloy ingot.

[0023] (2) Preparation of zinc bath components: Melt the...

Embodiment 2

[0037] The steel used for galvanizing is Q235 containing (0.22% Si) steel plate, and the method adopted comprises the following steps and process conditions:

[0038](1) Binary master alloy refining: Weigh manganese and zinc, cerium and zinc in proportion by weight, place them in graphite crucibles, and refine them respectively. Among them: the manganese content in the zinc-manganese binary master alloy is 2%, the melting temperature of the zinc-manganese master alloy is 790°C, and the holding time is 3 hours; the cerium content in the zinc-cerium binary master alloy is 3%, and the zinc-cerium master alloy The smelting temperature is 760°C, and the holding time is 3 hours. After each intermediate alloy liquid is kept warm, it is stirred, left still and the ash on the surface of the alloy liquid is removed, and then poured into an intermediate alloy ingot.

[0039] (2) Preparation of zinc bath components: Melt the zinc in the zinc pot and keep the temperature at 445°C, then ad...

Embodiment 3

[0043] The steel used for galvanizing is a Q235 containing (0.22% Si) steel plate, and the method adopted comprises the following steps and process conditions:

[0044] (1) Binary master alloy refining: Weigh manganese and zinc, cerium and zinc in proportion by weight, place them in graphite crucibles, and refine them respectively. Among them: the manganese content in the zinc-manganese binary master alloy is 2.5%, the melting temperature of the zinc-manganese master alloy is 780°C, and the holding time is 4 hours; the cerium content in the zinc-cerium binary master alloy is 2%, and the zinc-cerium master alloy The smelting temperature is 780°C, and the holding time is 2 hours. After each intermediate alloy liquid is kept warm, it is stirred, left still and the ash on the surface of the alloy liquid is removed, and then poured into an intermediate alloy ingot.

[0045] (2) Preparation of zinc bath components: Melt the zinc in the zinc pot and keep the temperature at 455°C, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com