Detection method and optical detection instrument for printed circuit board

A technology for printed circuit boards and optical detectors, which is applied in the directions of optical testing flaws/defects, instruments, and electrical measurement. It can solve the problems of heavy testing workload and complex IC solder pin identification and programming, and achieve the effect of simplifying the programming process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments.

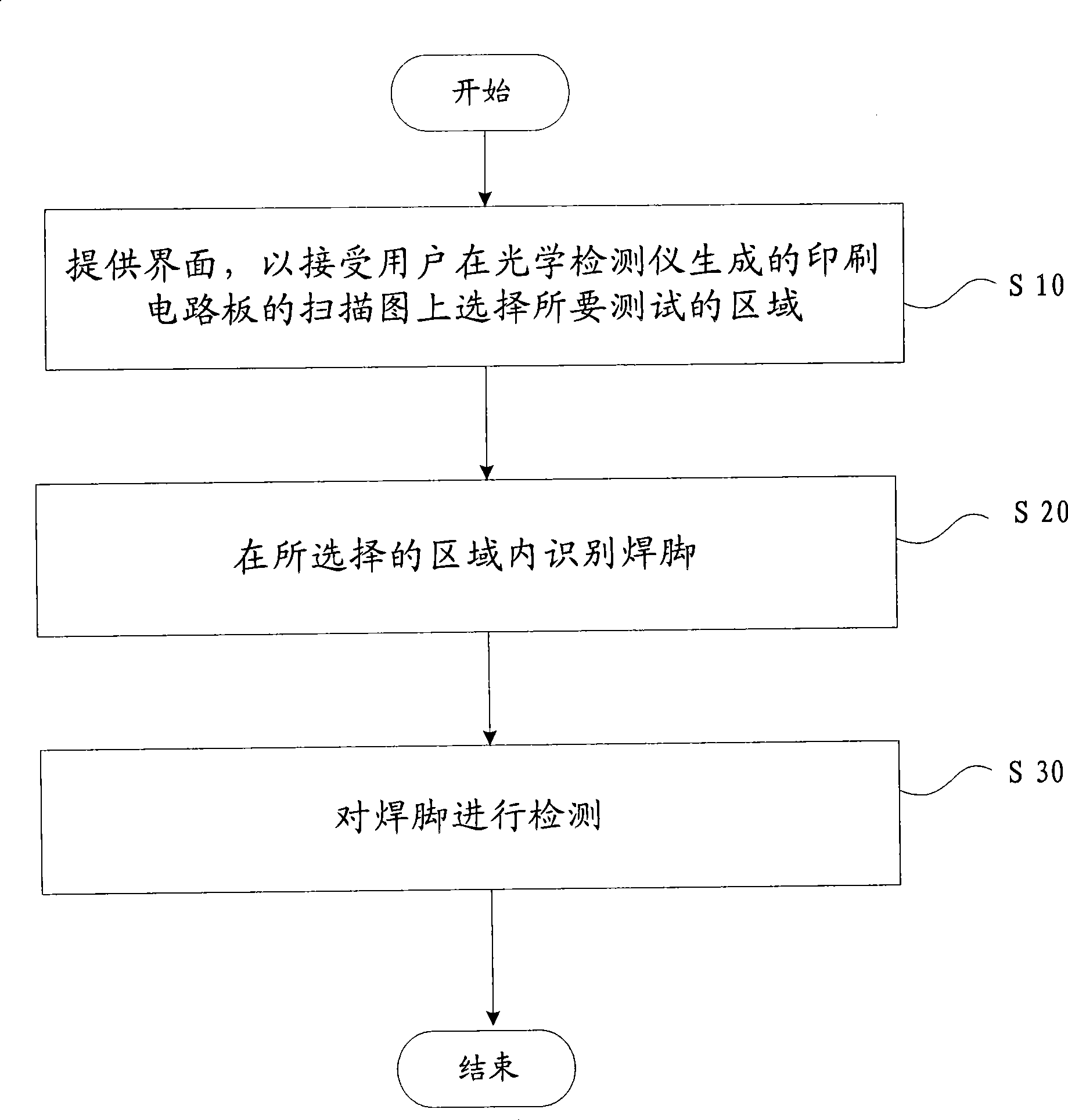

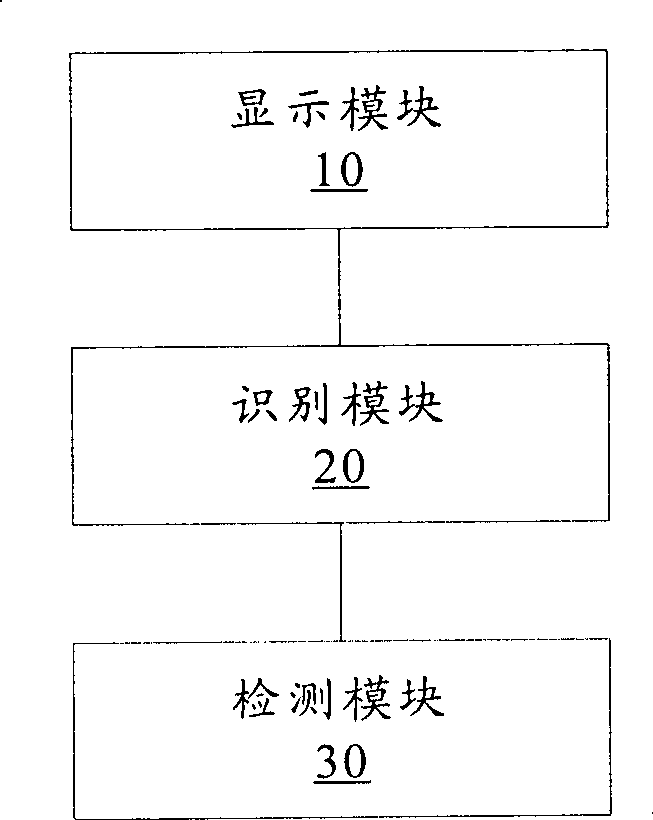

[0028] figure 1 A flow chart showing a method for detecting a printed circuit board according to an embodiment of the present invention includes:

[0029] Step S10, providing an interface to accept the user to select the area to be inspected on the scanned image of the printed circuit board generated by the optical detector, so that a frame can be programmed for a row of IC solder pins;

[0030] Step S20, identify the solder pins in the selected area, so that the number of IC solder pins and solder positions can be automatically identified by software;

[0031] Step S30, detecting the solder fillets.

[0032] This preferred embodiment can automatically identify the welding feet in the area selected by the user during detection, thereby solving the problem that the existing optical detector of the printed circuit board needs to manu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com