Self balance type punching riveting gun and control method thereof

A self-balancing, punching riveting technology, which is applied in the field of self-balancing riveting guns and its control, can solve the problems of time-consuming and labor-consuming programming of punching riveting robots, insufficient occlusal amount of riveting points, and shape and position deviation of connecting parts. Achieve the effects of shortening the programming time, ensuring the quality of punching and riveting, and eliminating the deviation of shape and position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

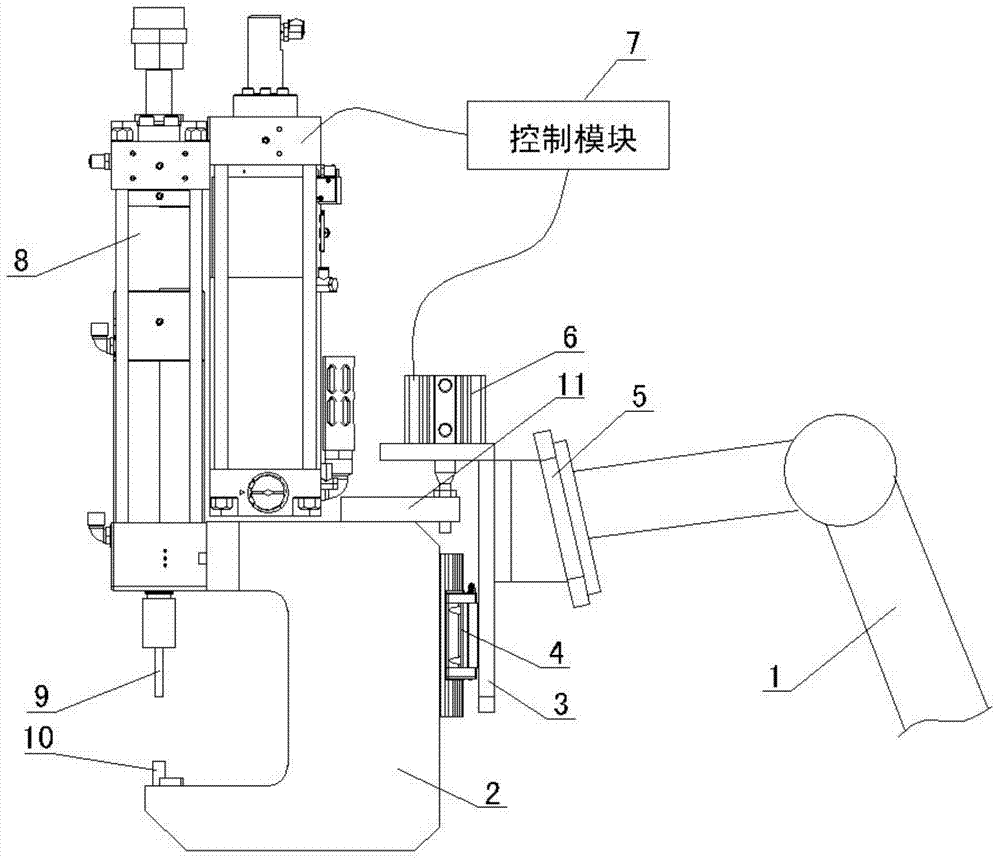

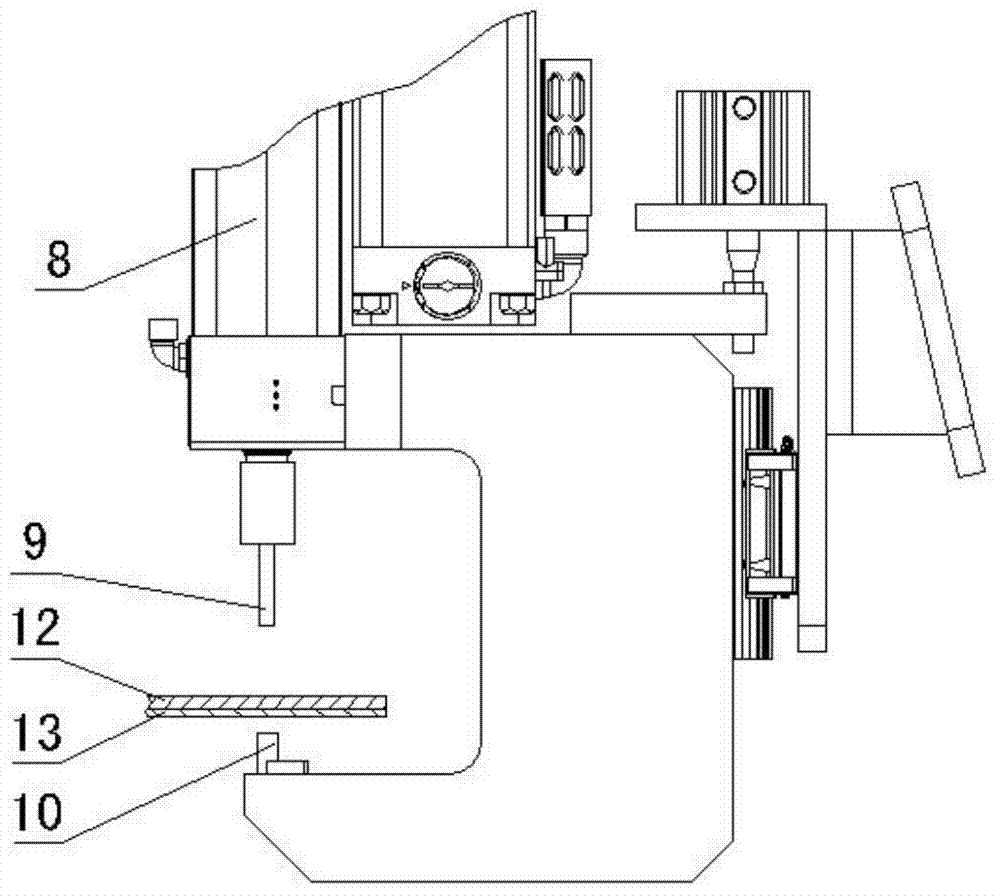

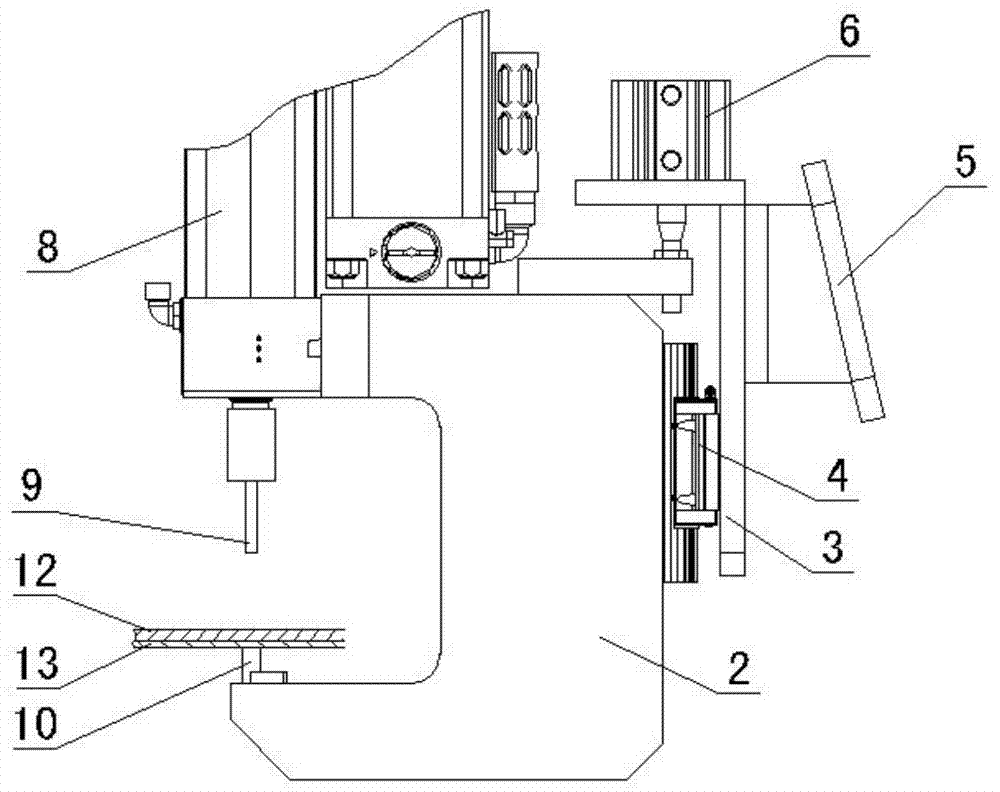

[0020] see figure 1 , the structural form of the self-balancing riveting gun in this embodiment is:

[0021] With the bracket 3 as the base, the bracket 3 is fixedly connected with the mechanical arm 1 through the flange 5 , and the mechanical arm 1 drives the movement of the bracket 3 .

[0022] A "C" type pliers body 2 is set, and its two ends at the upper and lower relative positions respectively form an upper jaw and a lower jaw; The guide rail in the guide rail slider mechanism is a vertical linear guide rail 4; a balance cylinder 6 is fixedly installed on the bracket 3, so that the piston rod in the balance cylinder 6 is fixedly connected with the "C" type pliers, figure 1 Shown in the figure is that the connecting plate 11 is fixedly arranged on the "C" type caliper body 2, the balance cylinder 6 is fixedly arranged on the bracket 3, and the piston rod in the balance cylinder 6 is fixedly connected with the connecting plate 11 at the rod end.

[0023] On the top of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com