Fixed screw rod for plasma cutting machine transformer

A technology of plasma cutting machine and fixing screw, which is applied in the direction of transformer/reactor installation/support/suspension, etc. It can solve the problems of short service life, large loss and low efficiency of the whole machine, and achieve the effect of reducing leakage reactance and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

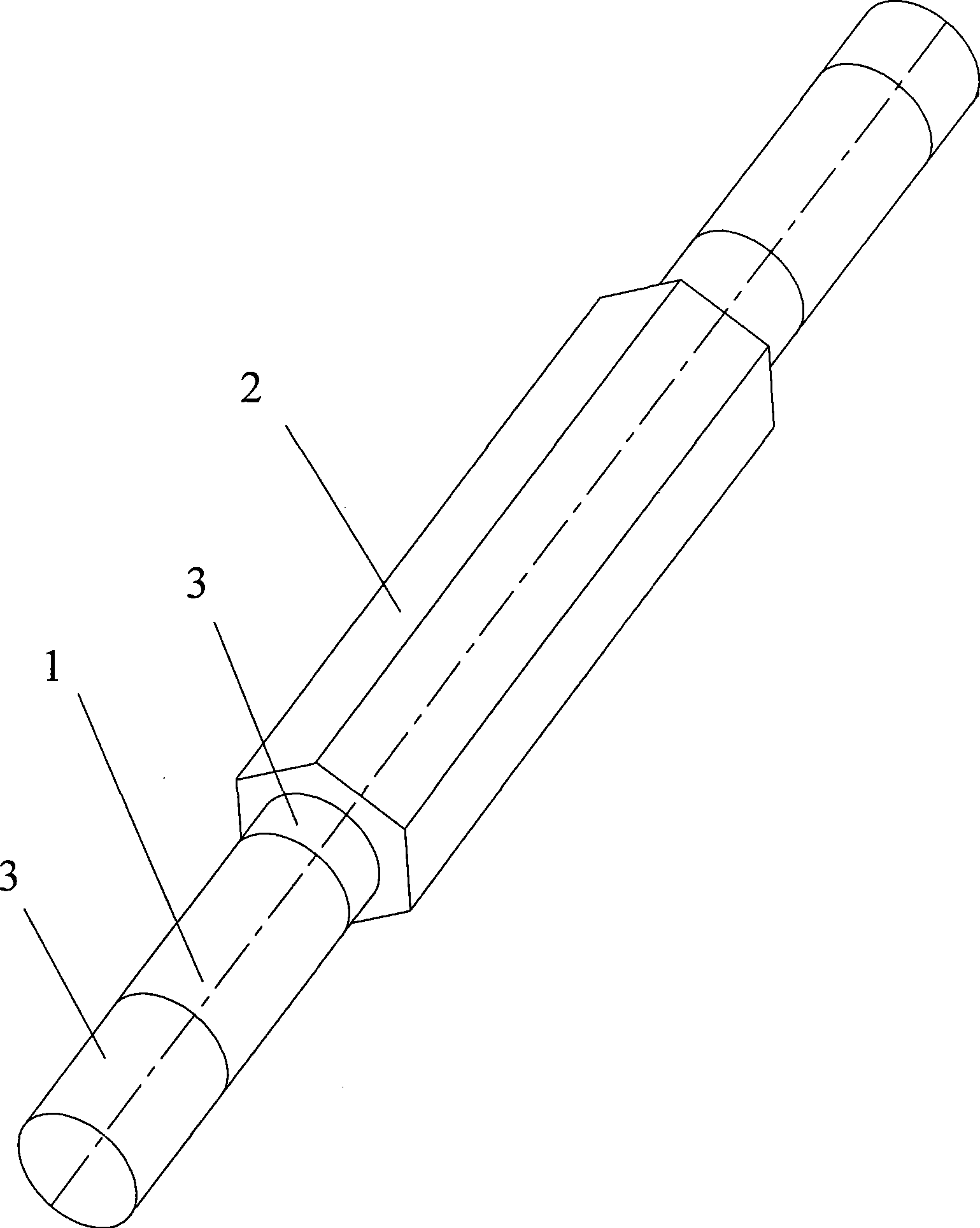

[0010] As shown in the figure: a non-magnetic material layer 2 is provided on the surface of the middle section of the screw body 1 . The two ends are still ordinary iron screws. And external threads 3 are respectively arranged at the middle section and both ends of the screw body 1 .

[0011] The non-magnetic material layer 2 is a copper alloy layer.

[0012] The non-magnetic material layer 2 and the screw 1 are connected to each other by an external thread 3 located in the middle.

[0013] The shape of the non-magnetic material layer 2 is a hollow polygonal cylinder.

[0014] The screw achieves the best match between performance and cost, and has great practicability in high leakage reactance transformers.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com