Motor for reducing mechanical losses by decreasing base size

A technology of mechanical loss and machine frame size, which is applied in the direction of electromechanical devices, mechanical energy control, electrical components, etc., and can solve problems such as inability to achieve energy saving and consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

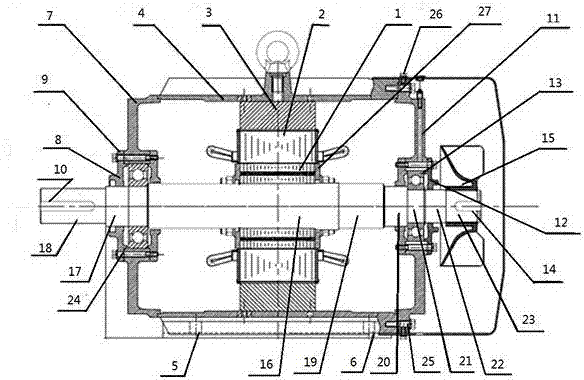

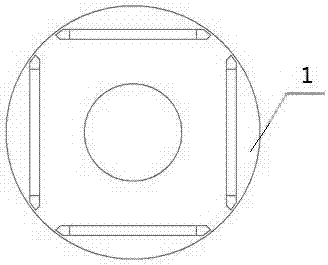

[0039] A kind of novel motor that reduces mechanical loss by reducing frame size, its composition comprises: 110kw / 3000rpm motor, described 110kw / 3000rpm motor has motor shaft, and described motor shaft passes through rotor iron core 1, and described The rotor core is connected to the permanent magnet 27, the rotor core passes through the stator core 2, the stator core is connected to the sleeve 3, the sleeve is connected to the base 4, and the bottom of the base is Open the No. 1 connection hole 5 and the No. 2 connection hole 6, the distance between the No. 1 connection hole and the No. 2 connection hole is 406 mm, the base is connected to the front end cover 7, and the motor shaft Through the front end cover, the distance between the center line of the motor shaft and the bottom of the base is 315 mm.

[0040] The new type of motor that reduces mechanical loss by reducing the size of the frame, the front end cover and the motor shaft are connected through a front bearing se...

Embodiment 2

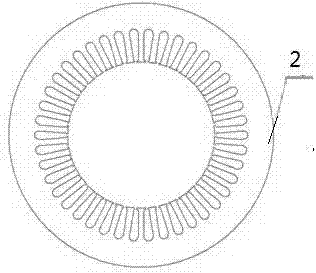

[0047] In the new motor that reduces mechanical loss by reducing the frame size described in Embodiment 1, the outer diameter of the stator core is D1=327mm, the inner diameter of the stator core is Di1=182mm, and the outer diameter of the rotor core is The diameter D2=179.4mm, the length L=260mm of the rotor core.

[0048] The number of stator slots is designed as 42 slots and 4 poles. The inclined slots are reduced from the original Y2 motor inclined 1.25 slots to 0.5 slots, and the leakage reactance of the inclined slots is reduced. At the same time, the span is 9 short-distance windings, and the harmonic content is greatly reduced.

[0049] The new type of motor that reduces the mechanical loss by reducing the size of the frame, the existing 2-pole 3000rpm, in addition to the rotor roughness, air density and surface friction coefficient that affect the loss of the motor, not only the loss increases with the motor speed to the third power At the same time, it is also propor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com