Device for neutralizing static electricity

An electrostatic and electrostatic powder technology, which is applied in the field of electrostatic neutralization devices, can solve the problems of the reduced ability of metal plates to adsorb charged powder, affect the stability of product coating thickness, and difficult to clean quickly. Intelligent and easy to clean up

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

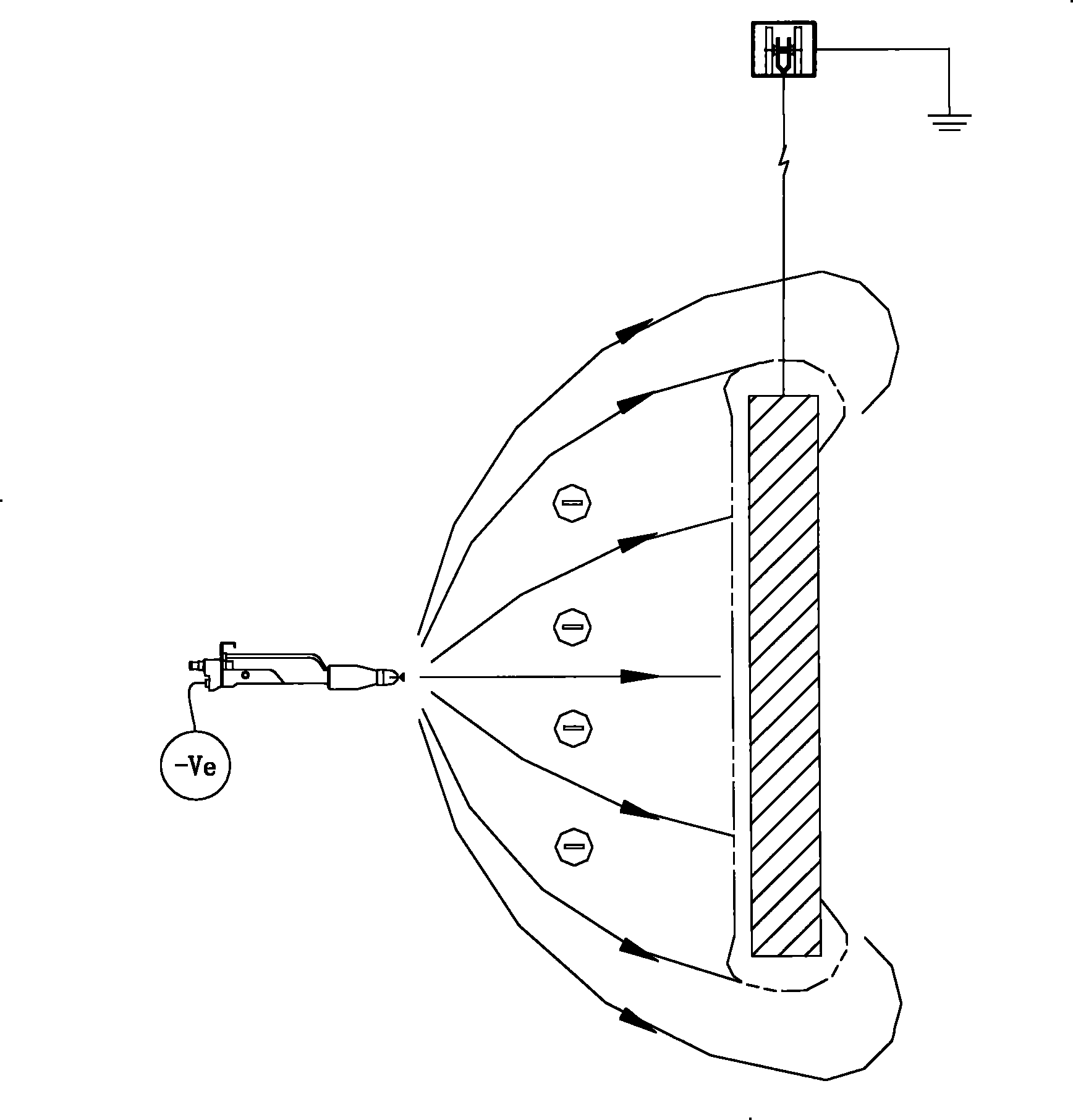

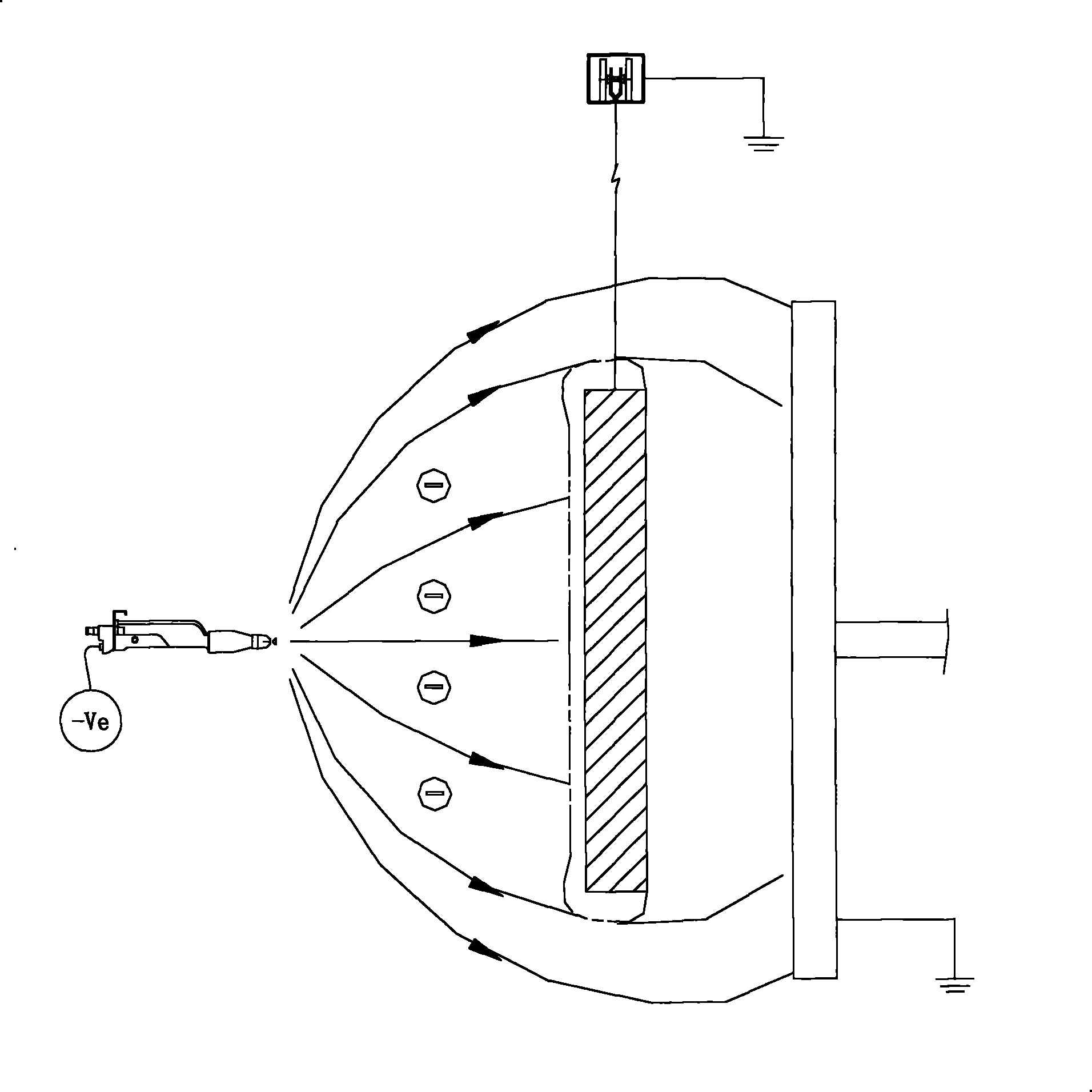

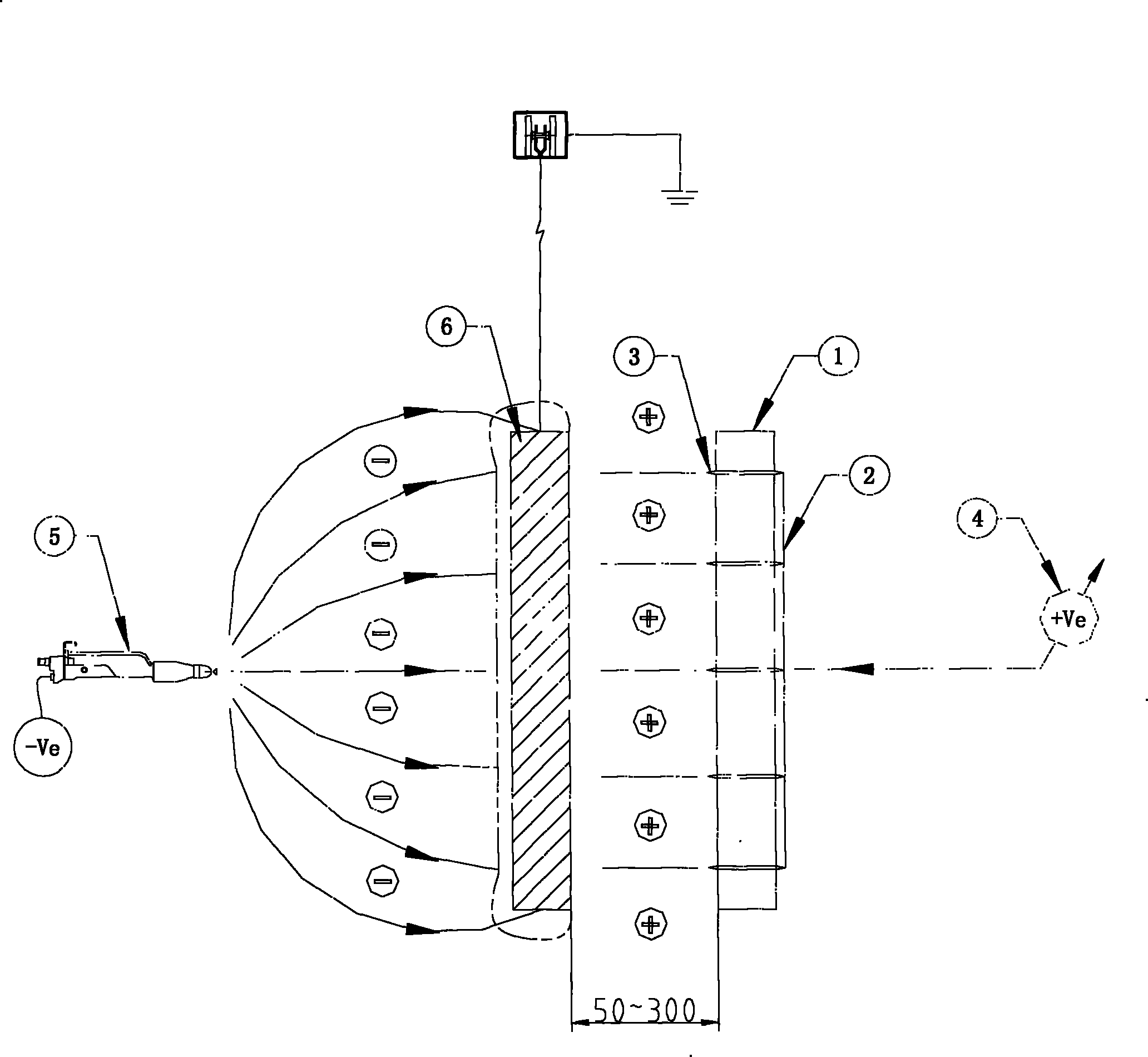

[0021] Such as image 3 , The electrostatic neutralization device according to the present invention comprises: an insulator 1 , a power cord 2 at the back of the insulator 1 , and several discharge needles 3 connected to the power cord 2 . The several discharge needles 3 are installed on the insulator 1 at a certain interval, and are perpendicular to the axial direction of the insulator 1; the discharge needles 3 are connected to the power line 2, and are used to generate charges of opposite polarity to those produced by the electrostatic spray gun Ions, so that the charged powder is neutralized when it exceeds the median line of the spraying piece 6, falls aside, and will not stick to the spraying piece 6.

[0022] The opposite voltage power supply generator 4 is connected to the discharge needle through the power line 2, and the opposite voltage 4 connected to the discharge needle 3 can be adjusted in chain or independently with the voltage 5 of the electrostatic spray gun....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com