Multi-knife boring processing numerical control borer

A technology for boring and boring machines, applied in the field of multi-tool boring machining CNC boring machines, can solve the problems of affecting the machining accuracy, damage to the tool, easy to generate vibration, etc., and achieve the effects of improved machining accuracy, improved service life, and accurate transmission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

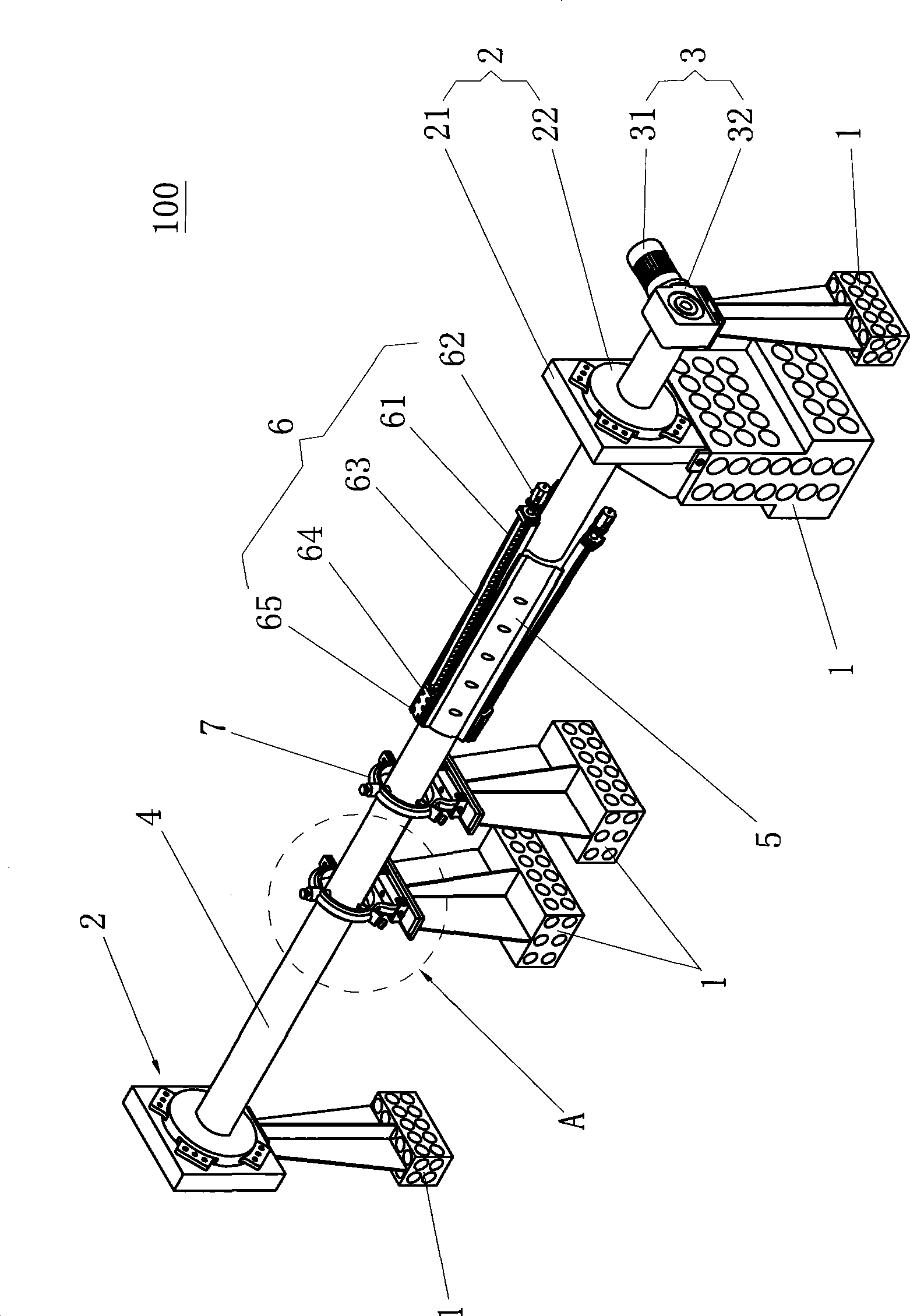

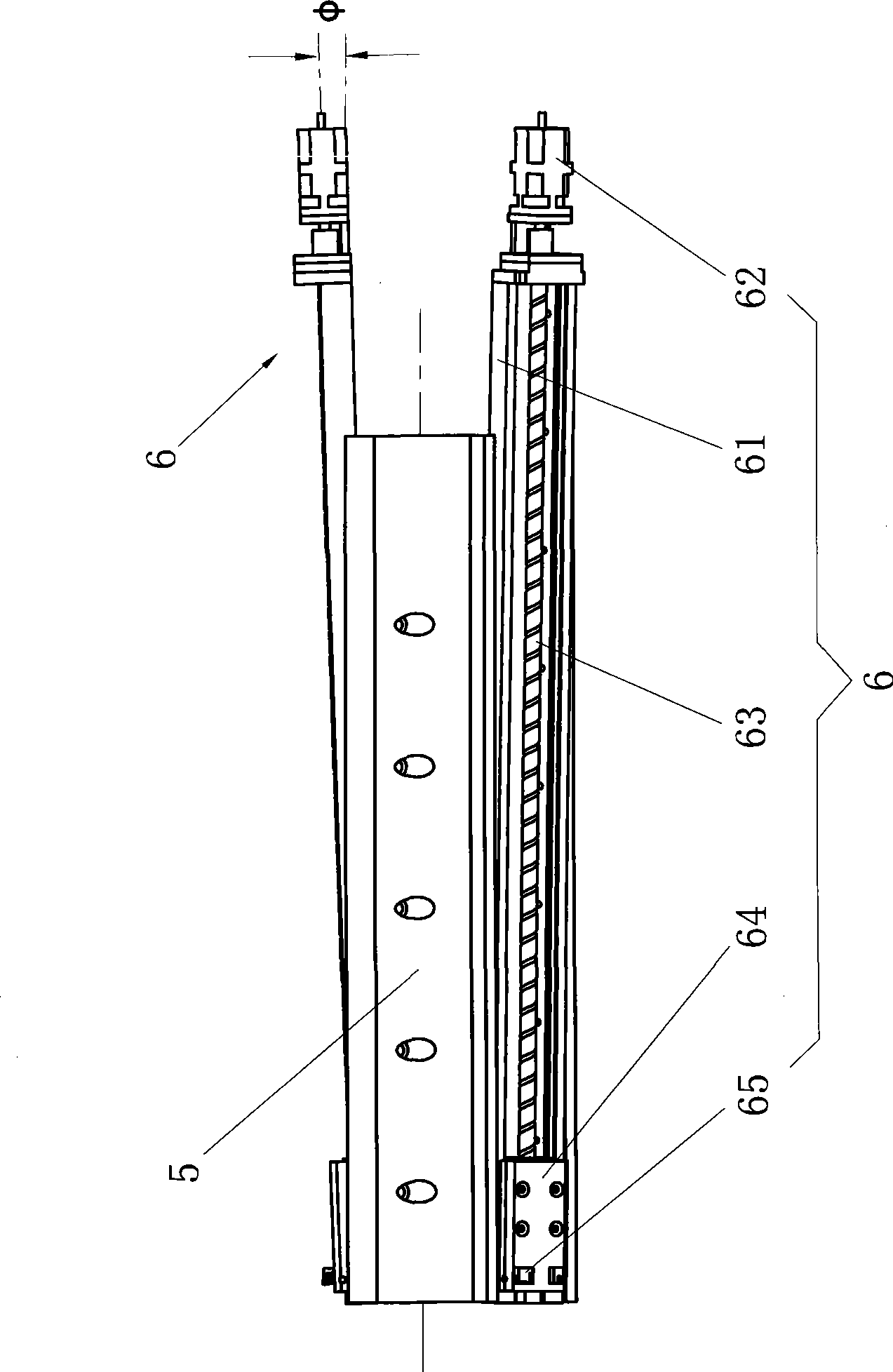

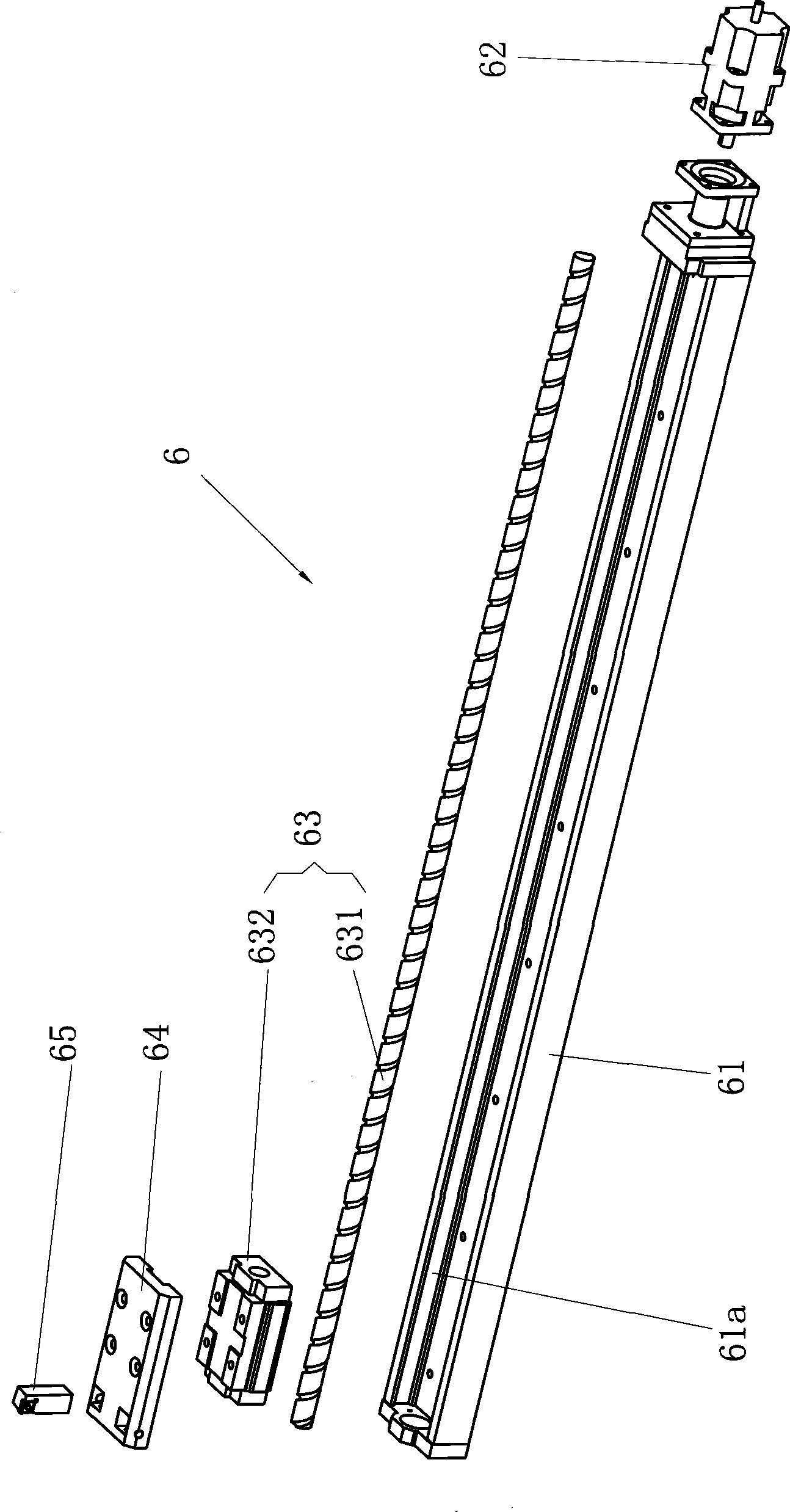

[0021] Such as figure 1 , figure 2 As shown, the CNC boring machine 100 for multi-tool boring processing includes five support components 1, self-aligning bearing components 2, main drive components 3, spindle 4, CNC platform (not shown in the figure), fixed sleeve 5 and three tapers Boring mechanism 6, the main shaft 4 is pivotally connected to the self-aligning bearing part 2, the self-aligning bearing part 2 is fixed on the support part 1, and the main driving part 3 is installed on one end of the main shaft 4 , the fixed sleeve 5 is detachably covered and fixed on the main shaft 4, and the three taper boring mechanisms 6 are evenly distributed on the fixed sleeve 5, and the main driving part and the taper boring mechanism are all compatible with the The numerical control platform is electrically connected, and the multi-cutter boring processing numerical control boring machine 100 of the present invention includes at least two tapered boring mechanisms 6 evenly distribut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com